Micro CNC Machining: Precision at Its Best

At TMC Technologies, we’ve carved a niche in the precision manufacturing world, specializing in Micro CNC Machining Iowa, a process that underpins the technological advancements seen across various industries. Our journey, rooted in a mission to exceed customer expectations through unmatched service and quality, has seen us become a beacon of innovation in custom-designed products. From the intricate components hidden within the gadgets we use daily to the critical parts that power aerospace exploration, our capabilities in micro CNC machining stand unrivaled.

Why Micro CNC Machining Is Crucial

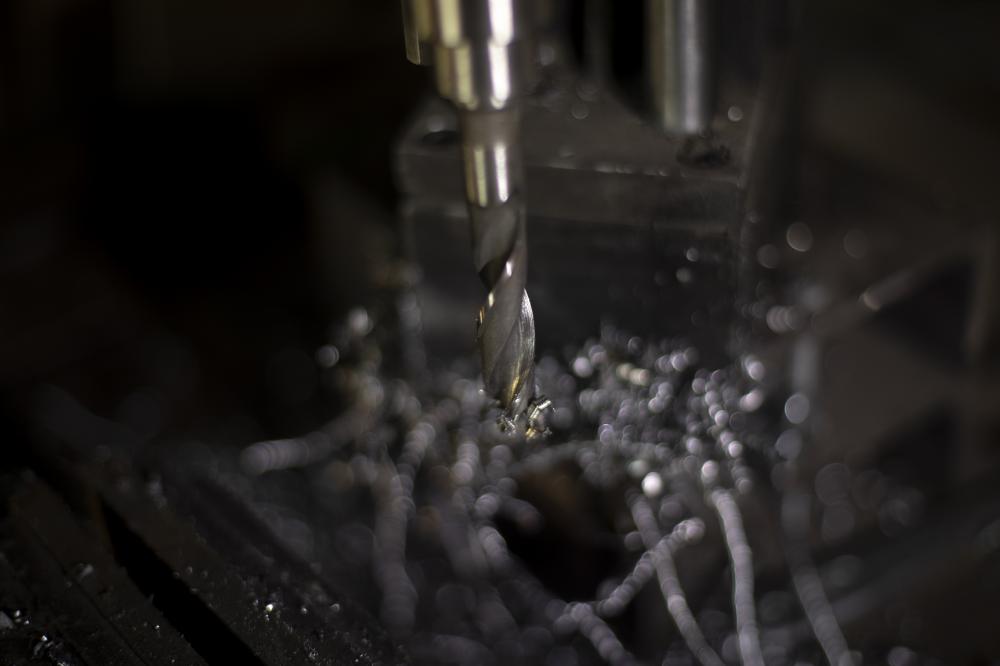

The marvel of micro CNC machining lies not just in the ability to produce small parts, but in the precision it brings to manufacturing. As we navigate a world where devices become smaller yet increasingly complex, the demand for micro CNC Machining in Iowa and beyond has surged. This technique allows for the creation of components with tolerances measured in micrometers, showcasing an unparalleled level of detail that traditional machining methods could never achieve.

Driving Innovations Across Industries

The implications of micro CNC machining are vast, touching upon sectors as diverse as healthcare, aerospace, and consumer electronics. By fostering advancements in these areas, we’re not just machining parts; we’re enabling progress and supporting innovations that shape our future.

TMC Technologies’ Capabilities in Micro CNC Machining Iowa

Our facility, nestled in the heart of Carol, Iowa, is a testament to our commitment to precision and quality. Equipped with state-of-the-art machinery and technology, we offer a suite of services that encompass the entire micro CNC machining process. From 3D modeling to CNC turning and machining, our in-house capabilities ensure that we maintain control over the quality and delivery of our products.

Industries We Serve

Our expertise in micro CNC machining allows us to serve a wide array of industries, including but not limited to Agriculture, Food Processing, Industrial Manufacturing, Firearms, and Medical/Military/Aerospace sectors. Each industry presents unique challenges and requirements, to which we’ve continuously adapted and excelled, thanks to our skilled team and flexible manufacturing processes.

Our Approach to Micro CNC Machining

At the core of TMC Technologies’ operations is a customer-centric approach. We understand that each project is unique, with its own set of complexities and challenges. This understanding drives our collaborative efforts, from initial design consultations to the final delivery of high-quality components. Our focus on service, quality, and innovation has not only set us apart but also cemented our reputation as a trusted partner in the manufacturing industry.

Quality, Precision, and Innovation

In the world of micro CNC machining, there’s no room for error. Precision is the name of the game, and at TMC Technologies, it’s a standard we live by. Our commitment to quality is evident in every component we produce, subjected to rigorous quality control measures to meet, if not exceed, customer expectations.

Staying Ahead with Advanced Technology

- State-of-the-art CNC Machinery

- Innovative 3D Modeling and Design

- Comprehensive In-House Capabilities

- Adaptability to Complex Projects

Embracing the latest advancements in CNC machining technology not only allows us to enhance our productivity but also to tackle projects of any complexity. This adaptability is crucial in an industry where the demands and specifications can change rapidly.

Collaborative Solutions for Every Need

One of the keystones of our success in micro CNC Machining Iowa has been our ability to collaborate closely with our clients. Understanding their needs, challenges, and objectives allows us to offer tailored solutions that are both practical and innovative. This partnership approach has led to numerous successful projects, with solutions that are as unique as the problems they solve.

Custom-Designed Products

Our specialization in custom-designed products means that we’re not just another machining company. We’re problem solvers, innovators, and partners in every project we undertake. Whether it’s a single prototype or a full production run, we apply the same level of dedication and precision to ensure the final product meets our high standards and client expectations.

Commitment to Sustainability

In every aspect of our operations, we strive to minimize our environmental impact. This commitment to sustainability is reflected in our efficient use of materials, energy-efficient processes, and waste reduction practices. We believe that being a leader in micro CNC machining also means being a steward of the environment, ensuring that our manufacturing processes are as sustainable as they are innovative.

Connect with TMC Technologies

Interested in learning more about our micro CNC Machining Iowa services or have a project in mind? Our team at TMC Technologies is ready to bring your ideas to life with precision and expertise. Contact us at 712-792-5512 or via email at [email protected] to discuss your project or inquire about our services. We’re more than just a manufacturing company; we’re your partner in precision and innovation.

As we continue to explore new horizons and push the boundaries of what’s possible in micro CNC machining, we invite you to join us on this journey of precision, innovation, and excellence. At TMC Technologies, we’re not just machining parts; we’re crafting the future, one micron at a time.

How much does CNC machining cost per hour?

When clients approach us at TMC Technologies, one of the first questions they often have is about the cost of CNC machining per hour. It’s a vital piece of information, especially when budgeting for projects. Directly speaking, CNC machining costs can vary widely depending on several factors including the complexity of the parts being produced, the type of material being used, and the specific machining processes required. Generally speaking, hourly rates can range anywhere from $75 to $125 or more. However, at TMC Technologies, we assess each project individually to ensure the most cost-effective approach without compromising quality. We believe in transparency, so we discuss all costs upfront and strive to optimize efficiency, passing on the benefits to our clients.

How much does CNC cutting cost?

CNC cutting costs are influenced by the type of operation needed, the material being cut, and the time required for the job. For example, cutting complex shapes from harder materials like stainless steel or titanium will naturally be more costly than simpler operations on softer materials like aluminum. At TMC Technologies, we leverage our state-of-the-art CNC machinery and our team’s expertise to provide cost-effective solutions. We always aim to offer competitive rates and can provide quotes based on your specific project requirements. Remember, investing in quality CNC cutting can save you time and money in the long run by minimizing the need for secondary processing and ensuring precision from the start.

Why is CNC milling so expensive?

CNC milling can be perceived as expensive due to the precision, expertise, and technology it requires. The cost is associated with several factors, including the sophistication of the machinery used, the time spent on design and programming, and the material costs. Moreover, the level of precision CNC milling provides, particularly in micro CNC machining, can’t be compared to any other method. At TMC Technologies, we see it as an investment rather than a cost. High-quality milling extends the life of the parts, improves performance, and often reduces the overall expense by minimizing failures and the need for replacements. We strive to provide value through our expertise, ensuring that every dollar you spend brings tangible benefits to your project.

What is CNC micro machining?

CNC micro machining is a specialized manufacturing process where parts are made with extremely tight tolerances, often measured in micrometers. It’s an area where we, at TMC Technologies, excel. Micro machining allows for the production of small, complex parts with an unprecedented level of precision, which is essential in industries such as medical, aerospace, and electronics. The intricacy of the components produced requires not just advanced CNC machinery but also a significant level of expertise. Our team’s ability to work at such small scales allows us to tackle projects that many other shops simply cannot, leading to innovations that push the boundaries of what’s possible in precision manufacturing.

How does micro CNC machining drive innovation across industries?

Micro CNC machining is not just about making parts smaller; it’s about making them smarter. By enabling the production of intricate components that fit into increasingly compact spaces, micro machining opens up new possibilities for product design and functionality across various industries. For example, in the medical field, it allows for the creation of highly precise surgical tools and implantable devices, directly impacting patient outcomes. In aerospace, it facilitates the development of lightweight, high-strength components that can withstand extreme conditions. At TMC Technologies, we see ourselves as more than manufacturers; we’re enablers of innovation. Through close collaboration with our clients, we help turn visionary ideas into tangible solutions, driving progress that can change the world.

Resources

- Machining Cloud – Machining Cloud is a cloud-based platform that provides access to cutting tool data, tool assemblies, and 3D cutting tool models, helping streamline the tool selection process for CNC machining.

- National Tooling and Machining Association (NTMA) – The NTMA is a trade association that represents the precision custom manufacturing industry in the United States, offering resources, networking opportunities, and advocacy for its members.

- National Institute of Standards and Technology (NIST) – NIST is a non-regulatory federal agency that promotes innovation and industrial competitiveness by advancing measurement science, standards, and technology.

- Society of Manufacturing Engineers (SME) – SME is a professional association for individuals and organizations in the manufacturing industry, offering resources, training, and certifications to advance manufacturing knowledge and skills.

- International Organization for Standardization (ISO) – ISO is an independent, non-governmental international organization that develops and publishes international standards to ensure the quality, safety, and efficiency of products, services, and systems.