Introduction: The Machine Shop Landscape in Iowa, USA

Tucked away in the heartland of the United States, Iowa is more than just rolling fields of corn and soybeans. It’s a hidden gem for the manufacturing industry, a haven for machine shops. These establishments, including the top-rated CNC lathe shops in Iowa, USA, play a vital role in the state’s vibrant manufacturing sector. From aerospace to automotive to medical industries, machine shops in Iowa provide a wide array of services, delivering precision-made parts that ensure the accuracy and longevity of industrial machinery.

In this article, we’re going to delve into the machine shop landscape in Iowa, exploring what these shops do, their prevalence in the US and specifically in Iowa, and highlighting some of the notable machine shops in the state. We’ll also shine a spotlight on TMC Technologies, a highly regarded CNC machine shop located in Carroll, Iowa.

If you’re a manufacturing company in need of CNC lathe parts or additional machining services for custom applications, this guide will help you navigate through the machine shop landscape in Iowa and find the perfect match for your needs. With a strong commitment to quality and reliability, these Iowan machine shops could be the solution to your pain points, ensuring the accuracy and longevity of your machinery. So let’s dive in and discover what the machine shop landscape in Iowa, USA has to offer.

Understanding What a Machine Shop Does

A machine shop is like the heartbeat of the manufacturing industry, tirelessly working to keep things running smoothly. But what exactly does a machine shop do? To fully appreciate the value that machine shops in Iowa, USA bring, we need to delve into the core functions of these establishments.

The Role of a Machine Shop in Manufacturing

Machine shops, such as TMC Technologies, are primarily involved in the production of precision components, which are critical elements in the function and longevity of various types of machinery. These specialized establishments utilize advanced technology and skilled craftsmanship to transform raw materials into finished products with exact specifications.

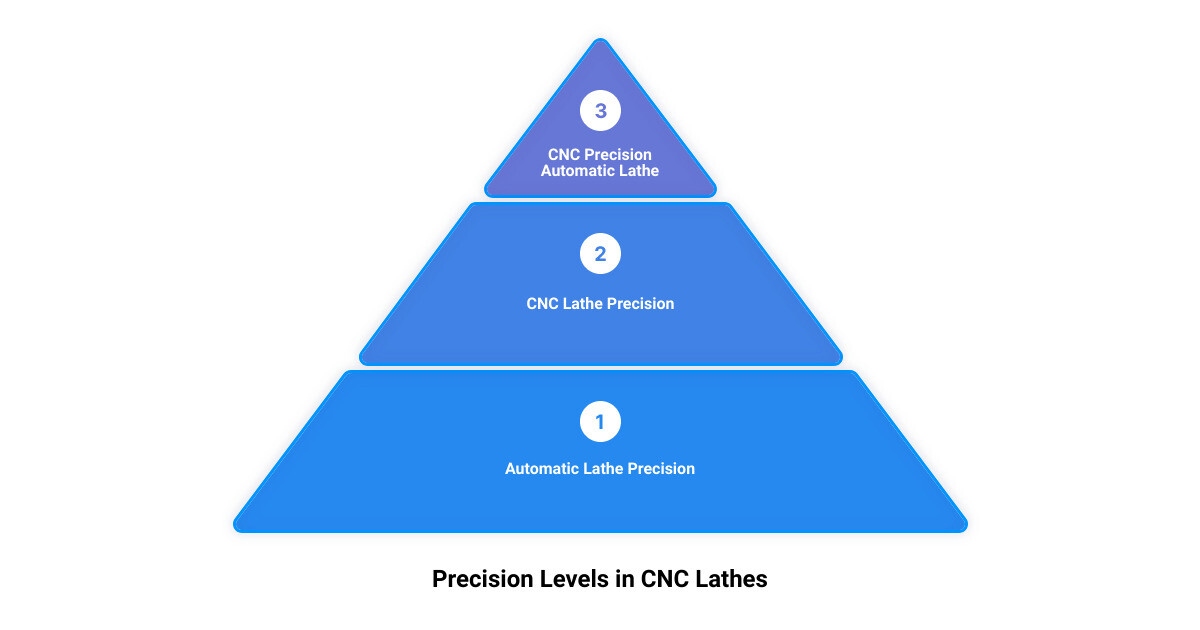

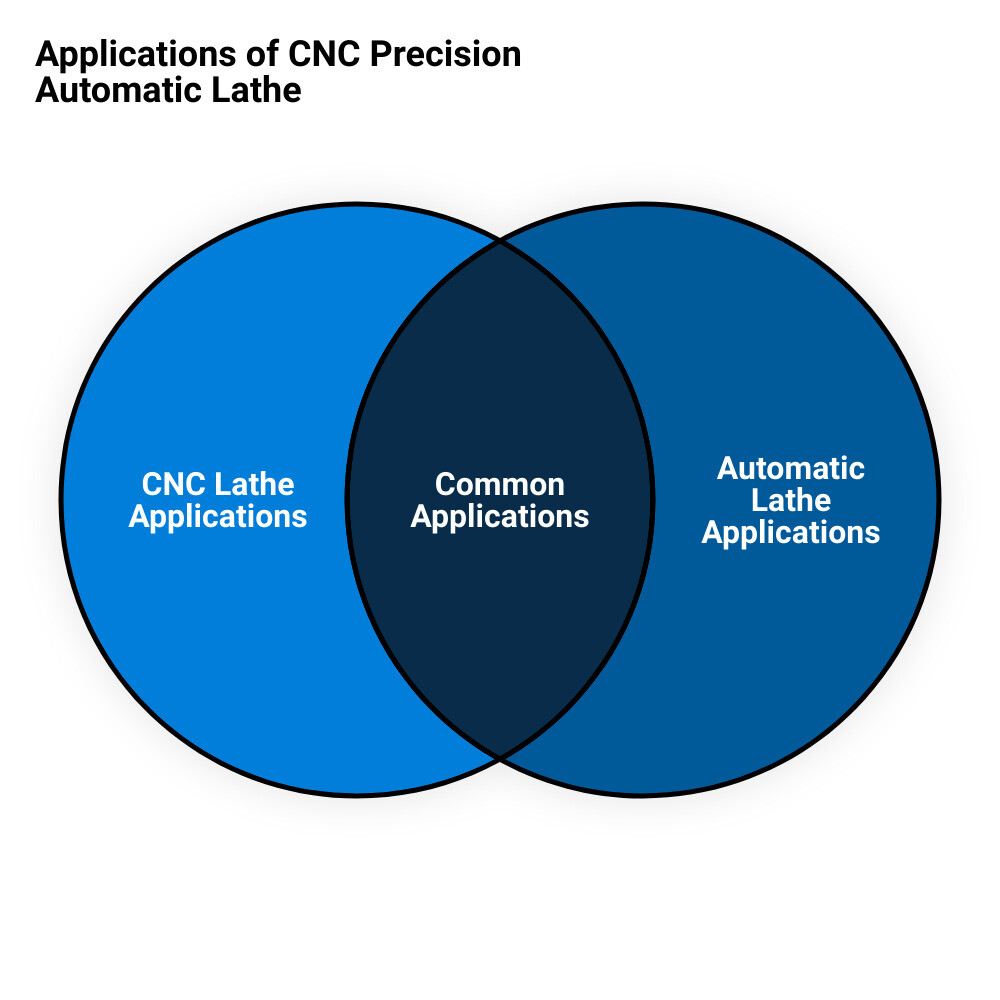

The heart of a machine shop is its CNC lathe, a highly sophisticated machine that shapes a workpiece through a process known as turning. Controlled by a computer program, CNC lathes ensure impressive accuracy and repeatability, taking machining from a manual, labor-intensive process to an automated, highly precise one. This precision is crucial in industries ranging from automotive to aerospace, medical devices to intricate firearms, where even the slightest deviation from specifications could lead to significant problems.

The Variety of Materials Worked on in a Machine Shop

Machine shops are not limited to working with just one type of material. They handle a wide array of materials, each bringing its unique challenges and opportunities in the machining process. This versatility is a testament to the machine shop’s adaptability and technical prowess.

Some of the most common materials machine shops work with include stainless steel, aluminum, and production-grade polymers. However, the list doesn’t end there. Some machine shops can also work with other materials, such as glass or wood, depending on the specific needs and requirements of their clients.

In a machine shop, the possibilities are endless, and the boundaries are continually being pushed. From prototype parts to high-volume production runs, machine shops offer a range of solutions and can provide a variety of surface finishing options such as anodizing, electroless nickel plating, and powder coating.

As we journey through the landscape of Iowa’s machine shops, it’s clear that these establishments play a vital role in the manufacturing sector. They are the silent heroes behind the products we use every day, and their contribution to the economy cannot be overstated. Now, let’s delve deeper into the prevalence of machine shops in Iowa and the US.

The Prevalence of Machine Shops in the US and Iowa

Stepping into the world of manufacturing, one can’t help but notice the sheer number of machine shops scattered across the United States. These facilities serve as the backbone of various industries, providing high-quality parts that keep the wheels of the economy turning. But how many of these establishments are there, and what is Iowa’s contribution to this landscape? Let’s find out.

The Number of Machine Shops in the US

From the bustling streets of New York to the quiet corners of small towns, machine shops are a ubiquitous sight in the US. As of September 24, 2023, the United States is home to a staggering 27,126 machine shops. These facilities offer a broad array of services, from traditional machining to advanced CNC operations, catering to diverse industries, from automotive to aerospace.

The Significance of Iowa in the US Machine Shop Industry

But what about Iowa? Where does it stand in this bustling machine shop ecosystem? While the specific number of machine shops in Iowa isn’t stated, the state has a robust presence in the machining and manufacturing industry. Iowa is home to top-rated CNC lathe shops like TMC Technologies, which are known for their high-quality services and commitment to customer satisfaction.

Iowa’s machine shops serve a multitude of industries, showcasing their versatility and adaptability. These establishments contribute significantly to the local economy, providing jobs and supporting local businesses. Moreover, they offer a range of services, from precision machining to supply chain management, meeting the diverse needs of their clients.

It’s also worth noting that Iowa’s central location in the US makes it a strategic hub for manufacturing and distribution. This, coupled with the state’s strong work ethic and commitment to quality, has made it a preferred destination for businesses seeking reliable machining services.

So, whether you’re in need of complex CNC lathe parts for your industrial machinery or additional machining services for custom applications, Iowa’s machine shops are ready to deliver. With their expertise and dedication, they’re indeed a testament to the state’s significant role in the US machine shop industry.

Highlighting Notable Machine Shops in Iowa

Beyond its vast fields of corn and soybeans, Iowa is also home to a wealth of machine shops, each with its unique strengths and specialties. Let’s highlight some notable industry players that are helping shape Iowa’s vibrant machine shop sector.

Eldridge Welding & Machine: A Century-Old Institution

Established in 1895, Eldridge Welding & Machine has served the Des Moines area with high-quality machine and welding work for over a century. With their large capacity machinery and a reputation for delivering excellent service, Eldridge Welding & Machine is a testament to Iowa’s rich industrial heritage.

P & P Small Engines: A Testament to Quality Service

Although the source did not provide information on P & P Small Engines, it is worth noting the importance of small engine repair shops in the state, given Iowa’s large farming community.

Marlie’s Garage: A One-Stop Shop for Auto Repair

While the source did not specifically mention Marlie’s Garage, auto repair shops in Iowa play a crucial role in keeping the state’s transportation systems running smoothly.

Earl’s Tire: A Leader in Automotive Services

Again, although the source did not mention Earl’s Tire, tire shops in Iowa are critical in maintaining the safety and efficiency of vehicles on the road.

Tinker Tooling: A Specialist in Local Services

While the source did not include specifics on Tinker Tooling, local service providers, in general, are key to supporting the needs of the community and contributing to the local economy.

Hawkeye Machine: A Silent Contributor

Details on Hawkeye Machine were not provided in the source, but any machine shop in Iowa contributes to the local economy and provides essential services to various industries.

Koenig Engineering & Machine: A Pioneer in Metal Fabrication

Although not specifically mentioned in the source, engineering and machine shops like Koenig Engineering & Machine provide specialized metal fabrication, a crucial service in many industries.

Fontanini Machining & Tooling: A Master of Sandblasting

Once again, while the source did not mention Fontanini Machining & Tooling, it’s important to note the role of shops specializing in specific services like sandblasting in the broader machine shop industry.

Howe Welding and Metal Fabrication: A Veteran in the Field

While the source did not provide information on Howe Welding and Metal Fabrication, welding and fabrication shops are integral to the machine shop industry, providing a wide range of services from simple welding jobs to complex metal fabrications.

These diverse machine shops, and many others like them in Iowa, play a crucial role in supporting the state’s robust manufacturing sector, contributing to its economic growth, and providing invaluable services to numerous industries. They truly set Iowa apart as a machine shop haven.

Spotlight on TMC Technologies: A CNC Machine Shop in Carroll, Iowa

When it comes to machine shops in the heartland of America, one standout is TMC Technologies. Tucked away in Carroll, Iowa, TMC Technologies has been a cornerstone in the realm of CNC lathe parts manufacturing for over three decades.

TMC Technologies: A Provider of High-Quality CNC Lathe Parts

TMC Technologies has built a reputation for delivering high-quality, precision-machined components that are crucial for various industrial machinery. The company’s focus on precision and quality is evident in every CNC lathe part they produce. Whether it’s a prototype part or a full production run, TMC Technologies ensures that each component meets stringent quality standards and precise specifications.

The Unique Selling Proposition of TMC Technologies

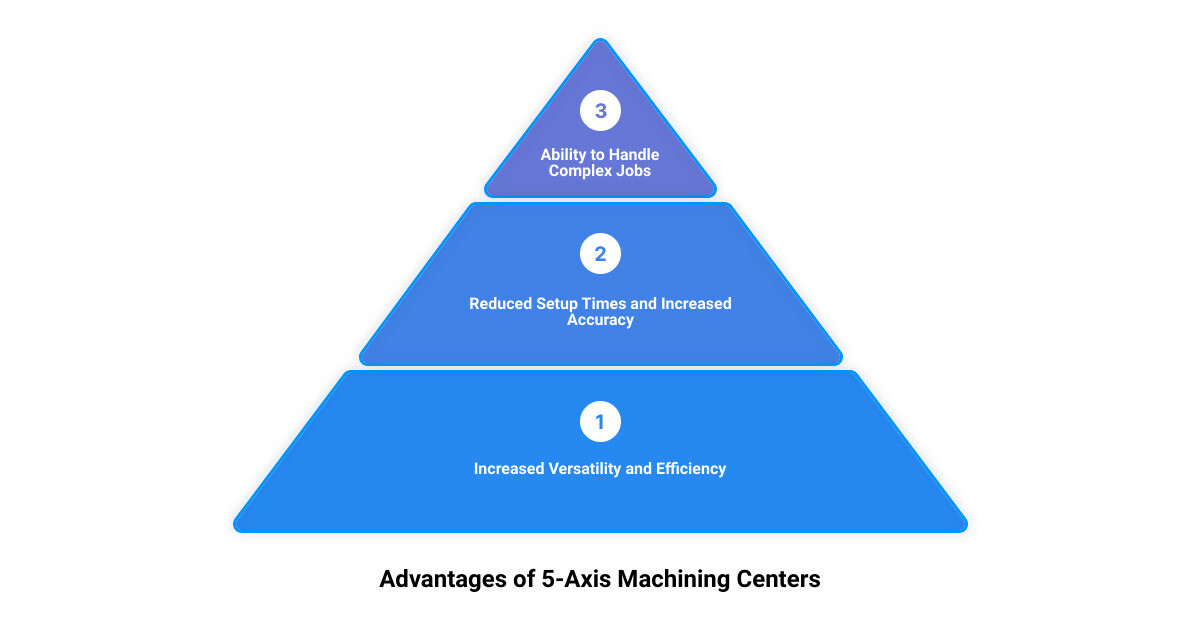

TMC Technologies distinguishes itself with an unwavering commitment to precision, quality, and customer satisfaction. But their uniqueness doesn’t stop there; it extends to their ability to offer a comprehensive suite of machining services. From CNC milling and turning to grinding and fabrication, TMC Technologies cover all bases of CNC machine shop services. Their team of highly trained CNC machinists, armed with the most advanced CNC machines, ensure that each project is completed accurately and on time.

The Additional Services Offered by TMC Technologies

Beyond CNC lathe parts, TMC Technologies also offers design and fabrication services for custom applications. Recognizing that every client has unique needs, they are committed to providing tailored solutions. This focus on customization sets TMC Technologies apart as a leader in precision machining parts manufacturing.

Their service portfolio also encompasses grinding, various secondary operations, heat treating, and light fabrication/assembly. This range of services allows TMC Technologies to position itself as a one-stop-shop for all things CNC, offering convenience and efficiency for their clients.

In the landscape of machine shops in Iowa, TMC Technologies shines as a beacon of precision, quality, and customer satisfaction. Their dedication to their craft, coupled with their vast range of services, makes them a top choice for businesses seeking top-tier CNC lathe parts and machining services. TMC Technologies is an essential pillar in the robust machine shop industry of Iowa, further solidifying the state’s reputation as a machine shop haven.

The Importance of Supporting Local Machine Shops in Iowa

Just as a well-oiled machine relies on each component to function optimally, so does the economic engine of Iowa. Supporting local machine shops in Iowa is not just about sourcing high-quality CNC lathe parts; it’s about fueling the local economy and fostering a thriving manufacturing industry. Two key elements play pivotal roles in this endeavor: business-friendly leaders and the economic impact of local machine shops.

The Role of Business-Friendly Leaders in Supporting the Manufacturing Industry

The manufacturing landscape is heavily influenced by policies and regulations set by leaders in government and industry. As Pete Beatty, owner of MediaWebLink, points out, the decline of some American machine shops can be attributed to professional politicians with little or no business experience. This emphasizes the need for business-friendly leaders who understand the intricacies of the manufacturing industry and can implement policies that foster its growth.

In Iowa, this means advocating for tax policies that incentivize manufacturing, streamlining regulations that impede growth, and promoting training and education programs that equip the workforce with necessary skills. Such leadership can create a nurturing environment where machine shops like TMC Technologies can flourish and contribute to the local and national economy.

The Impact of Local Machine Shops on the Iowa Economy

Machine shops are more than just providers of precision-made parts. They are significant contributors to Iowa’s economy, providing employment, boosting local spending, and contributing to the state’s GDP. With a total of 27,126 machine shops in the United States as of September 24, 2023, the potential economic impact is substantial.

Machine shops in Iowa, like TMC Technologies, not only manufacture high-quality products but also create jobs, pay taxes, and contribute to the local economy. By choosing to support these local businesses, companies are investing in Iowa’s economic resilience. Furthermore, supporting local machine shops promotes a sustainable supply chain, minimizing the environmental impact of long-distance shipping and promoting responsible manufacturing practices.

It’s clear that Iowa’s machine shops aren’t just important for manufacturing CNC lathe parts. They play a crucial role in supporting the local economy, creating jobs, and promoting sustainable business practices. In this context, Iowa truly stands as a machine shop haven, and supporting these local businesses is an investment in the state’s economic future.

Conclusion: Iowa as a Machine Shop Haven

As the sun sets on our exploration of the vibrant machine shop landscape of Iowa, USA, it’s clear that this midwestern state stands as a beacon for precision machining and manufacturing services. With a rich history of manufacturing and a promising future, Iowa indeed shines as a machine shop haven.

The state’s machine shops, such as the top-rated TMC Technologies and Sadler Machine Co., have proven time and time again their commitment to delivering high-quality services. From producing high-quality CNC lathe parts to offering additional services like prototyping or reverse engineering, these shops have shown remarkable expertise and dedication. They’ve adapted to new technologies, maintained stringent quality control procedures, and managed to keep their services cost-effective, which is a testament to their resilience and innovation.

Furthermore, these local machine shops play an integral part in boosting the Iowa economy. They are job creators, innovation hubs, and drivers of sustainable business practices. By supporting these local businesses, we are not only investing in high-quality, precision-made parts for our own operations but also contributing to the prosperity of the state and its residents.

Of course, the search for the perfect machine shop doesn’t end at Iowa’s borders. Neighboring states like Colorado, Illinois, Kansas, Minnesota, Nebraska, and Wisconsin also offer competitive services that might just have the specific solution you need. But as we’ve discovered, when it comes to a thriving machining industry, Iowa indeed holds its own.

In conclusion, whether you’re a local business in need of CNC lathe parts or a manufacturing company from another state looking for reliable suppliers, Iowa’s machine shops are well-equipped to meet your needs. With their strong dedication to quality, precision, and customer service, these local businesses are not just machine shops; they’re partners in building a brighter, more sustainable future for the manufacturing industry. It’s clear that in Iowa, you’re not just in a state – you’re in a machine shop haven.