Introduction to Precision Machining

In a world where precision and accuracy are paramount in manufacturing, precision machining has emerged as a key player. This process plays a significant role in creating parts and components that play a critical role in various industries. But what exactly are high precision parts, and why are they so important? Let’s delve into the art of precision machining parts manufacturing.

Understanding High Precision Parts

High precision parts are essentially components crafted with an incredible level of accuracy. In the manufacturing industry, high precision machining refers to the creation of parts with tolerances in the single-digit micron range. When we move towards ultra-precision, we’re talking about tolerances in the sub-micron range. These precise tolerances ensure components fit perfectly into machinery and equipment, maintaining the seamless operation of these systems.

Examples of Precision Components

Precision components are everywhere, especially when it comes to industries that rely on precision and accuracy. A common example of precision components is those created using Computer Numerical Control (CNC) technology. This technology is commonly used to design and manufacture parts like suspension arms, machine shafts, valve bodies, and spindles. These are parts that require high precision due to their critical role in various machinery and equipment.

The Importance of High Precision Products

High precision machining is essential for industries that require tight tolerances and a high level of accuracy in their parts. The automotive, aerospace, and medical industries are prime examples of sectors that heavily rely on high precision machining. In these sectors, a slight flaw in a machined part can lead to catastrophic consequences, emphasizing the importance of precision in manufacturing.

In essence, the art of precision machining parts manufacturing is about ensuring reliability, safety, and efficiency in various industries. The manufacturing world depends on the precise creation of parts to keep machinery running smoothly, and companies like TMC Technologies are leading the way in this field.

The Role of Precision Machining in Custom Metal Parts Manufacturing

In the vast realm of custom metal parts manufacturing, precision machining plays a starring role. It’s the secret sauce that ensures the production of high-quality, precise parts that flawlessly integrate into larger assemblies.

The Use of Precision Machines in Building Custom Metal Parts

Precision machining is a subtractive process where material is systematically removed to create parts that match exact specifications. This process is often navigated with the assistance of CAD and CAM programs, which serve as the digital blueprints for the precision machining tools. This method facilitates the production of components like fittings, where consistency and accuracy are paramount.

Machines used in this process include precision CNC machines, lathes, and milling machines. At TMC Technologies, we utilize three-axis, four-axis, and five-axis CNC milling machines. These machines offer the capability to produce complex shapes and execute milling from any angle. Lathes rotate the workpiece against a cutting tool, producing parts with diameters ranging from 0.062 inches to 22 inches.

The Significance of Computer Numerical Control (CNC) Technology

The real game-changer in precision machining is the advent of Computer Numerical Control (CNC) technology. CNC precision machining is a process that leverages computer-controlled cutting tools to create precise components with exact dimensions.

CNC machines operate under sophisticated software, allowing for greater efficiency and less variance compared to other metal fabrication methods that involve more manual input. These machines work faster than human-operated machines, producing fewer errors, saving time, and reducing material waste.

In essence, CNC technology is the backbone of precision machining. It allows companies like TMC Technologies to create custom metal parts with high accuracy, repeatability, and efficiency, meeting the needs of various industries.

The use of precision machines in building custom metal parts and the significance of CNC technology cannot be overstated. Together, they form the cornerstone of precision machining parts manufacturing, contributing to the production of reliable, high-quality components.

TMC Technologies: A Leader in Precision Machining Parts Manufacturing

Grasping the delicate art of precision machining parts manufacturing, TMC Technologies shines as an industry leader. This company has carved out a niche for itself in this advanced and technically demanding field.

Overview of TMC Technologies

TMC Technologies, based in Iowa, is a top-tier supplier of CNC lathe parts crucial for various industrial machinery. With its focus on delivering high-quality components and a comprehensive suite of machining services, TMC Technologies has proven its mettle in the precision machining parts manufacturing landscape. The company’s expertise lies in CNC machine shop services, offering a gamut of capabilities that meet any CNC lathe parts requirements.

TMC Technologies’ Unique Selling Proposition

What sets TMC Technologies apart is its unwavering commitment to precision and quality. It’s not just about producing parts; it’s about crafting components that meet stringent quality standards and precise specifications. Each CNC lathe part that comes out of TMC Technologies is a testament to the company’s dedication to detail and accuracy. From prototype parts to a full production run, TMC Technologies delivers the highest quality of CNC lathe parts, competitively priced, and with fast delivery times.

TMC Technologies’ Specialization in CNC Lathe Parts

Specialization is the key to excellence, and TMC Technologies knows this well. The company’s specialization lies in CNC lathe parts, an area where precision and accuracy are non-negotiable. With a team of highly trained CNC machinists and the most advanced CNC machines at their disposal, TMC Technologies offers a wide range of CNC machine shop services. These include CNC milling, CNC turning, CNC grinding, and CNC fabrication services.

In addition, TMC Technologies also offers design and fabrication services for custom applications, understanding that every client has unique needs. This focus on customization further establishes TMC Technologies’ commitment to providing tailored solutions, reinforcing its position as a leader in precision machining parts manufacturing.

To sum up, TMC Technologies is more than a manufacturer; it’s a partner that understands your needs, values quality, and delivers precision. This dedication to excellence makes TMC Technologies a leading name in the world of precision machining parts manufacturing.

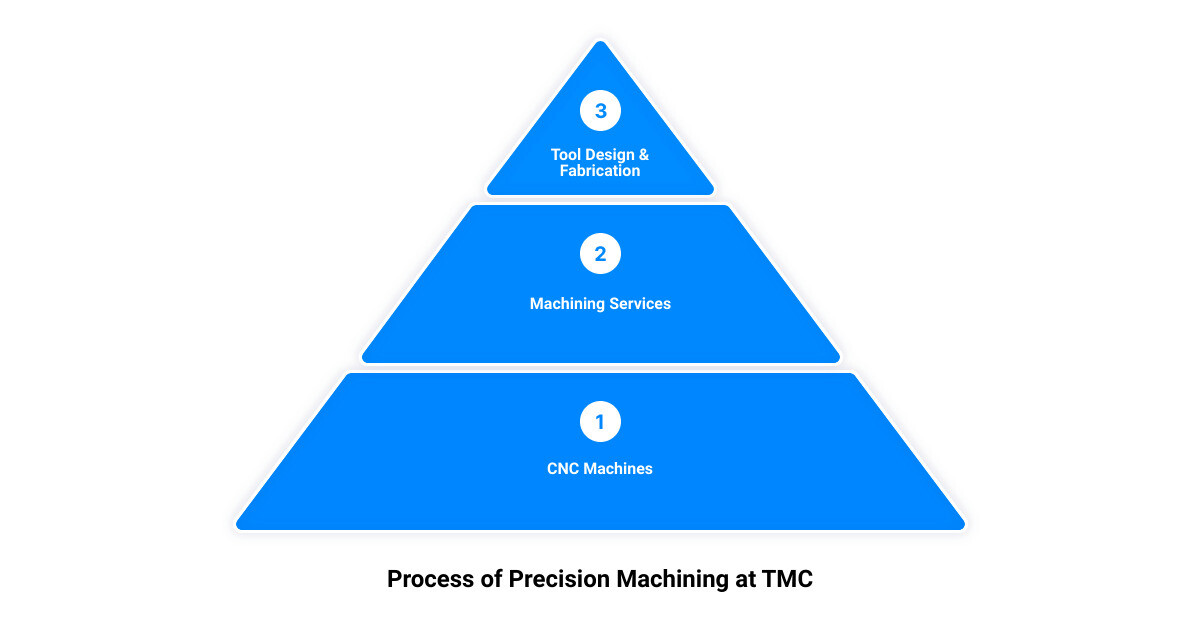

The Process of Precision Machining at TMC Technologies

Precision machining is often likened to an art form, with the machines acting as the artist’s brush. However, at TMC Technologies, the artistry extends beyond the machines themselves to the entire process of precision machining. This includes leveraging CNC machines, providing additional machining services, and crafting tools for custom applications.

The Role of CNC Machines in TMC Technologies

CNC machines are the backbone of TMC Technologies’ precision machining process. These machines are fed with digital blueprints containing the exact specifications for each part. This ensures the repeatability and accuracy of each piece, whether it’s a one-off prototype or a batch of thousands. TMC Technologies uses both three-axis and four-axis CNC milling machines, allowing for the production of complex shapes and milling from any angle. These CNC machines aren’t just faster than human-operated machines, they also make fewer errors, saving time and reducing waste.

Additional Machining Services at TMC Technologies

TMC Technologies understands that precision machining often requires more than just CNC milling. To meet the diverse needs of its customers, TMC Technologies offers a range of machining services, from centerless and cylindrical grinding to induction and conventional heat treating. These additional services ensure that each component produced meets the desired specifications and quality standards. Plus, TMC Technologies’ broad capabilities allow for high volume manufacturing and finishing operations, making it a one-stop-shop for precision machined parts.

Tool Design and Fabrication for Custom Applications at TMC Technologies

At TMC Technologies, the art of precision machining extends to the design and fabrication of tools for custom applications. The company’s in-house design and engineering services use advanced engineering software such as Master Cam, Gibbs Cam, and Solid Works to create custom tool designs. This ability to customize tools and parts to meet specific customer requirements sets TMC Technologies apart in the precision machining industry.

In conclusion, the process of precision machining at TMC Technologies is a well-tuned symphony involving CNC machines, a variety of machining services, and custom tool design and fabrication. This comprehensive approach ensures that every precision machined part produced is of the highest quality, meeting and often exceeding customer expectations.

Industries Served by TMC Technologies

As the curtain falls on the symphony of precision machining at TMC Technologies, it’s time to shift our focus towards the audience – the diverse range of industries that benefit from their precise and quality services.

Overview of Industries Served

TMC Technologies is not just a precision machining parts manufacturer; it’s a multifaceted provider of top-notch components serving various industries. The versatility and adaptability of their machining services have allowed them to cater to a range of sectors. From the food processing industry requiring high hygiene standards to the aerospace and military sector demanding utmost precision and durability, TMC Technologies is a trusted partner in providing tailor-made solutions.

Other industries served by TMC Technologies include the industrial sector, firearms, medical, and agriculture. Each of these industries has unique requirements and challenges, and TMC Technologies rises to the occasion with its expertise and commitment to quality.

The Importance of Precision Machining in Various Industries

With the ever-growing demand for innovation and efficiency, precision machining has become a necessity in various industries. Let’s take a closer look at why precision machining is so critical.

Food Processing: In this industry, precision machining is crucial for creating equipment that meets stringent hygiene and safety standards. TMC Technologies ensures that every part produced for this industry is not only accurate but also able to withstand the rigors of food processing environments.

Industrial: In the industrial sector, machinery and equipment need to be robust, reliable, and precise. TMC Technologies’ precision machining services guarantee parts that can endure heavy usage and harsh conditions while maintaining their functionality and efficiency.

Firearms: The firearms industry requires high precision parts for safety and performance. TMC Technologies manufactures components that meet the strict standards of this industry, ensuring reliability and durability.

Medical: Precision is of utmost importance in the medical industry, where even the smallest error can have significant consequences. TMC Technologies provides high-precision parts that ensure the accuracy and reliability of medical equipment.

Agriculture: The agricultural sector relies on robust and durable machinery. Precision machining from TMC Technologies ensures that agricultural equipment performs optimally and withstands the demands of farming environments.

Aerospace/Military: In the aerospace and military sector, precision machining is critical for the production of components that meet stringent safety and performance standards. TMC Technologies’ expertise in precision machining ensures the production of high-quality, durable, and reliable components for these industries.

In conclusion, the breadth and depth of industries served by TMC Technologies speak volumes about their versatility, adaptability, and commitment to delivering top-tier quality components. No matter the industry, TMC Technologies’ precision machining services are a game-changer, ensuring the accuracy, longevity, and efficiency of industrial machinery.

The Future of Precision Machining Parts Manufacturing

As we move forward in this technological age, the future of precision machining parts manufacturing becomes more exciting and complex. The art of precision machining is continuously evolving, driven by advancements in technology and the constant demand for improved efficiency, quality, and precision.

The Evolution of Precision Machining

Precision machining has come a long way from its humble beginnings. What started as manually-operated machines has now evolved into computer-controlled systems capable of creating intricate and high-precision parts. The introduction of Computer Numerical Control (CNC) technology was a significant milestone in the evolution of precision machining. This technology enabled machines to perform complex cutting tasks with extreme precision and consistency.

Today, precision machining is inextricably woven into the fabric of numerous industries, from automotive and aerospace to medical and electronics. It is the backbone of manufacturing, allowing companies to produce high-quality and reliable components that power our everyday lives.

The Impact of Technological Advancements on Precision Machining

Technological advancements have significantly impacted the precision machining industry. For instance, the incorporation of CAD/CAM software into the manufacturing process has revolutionized how machinists design and create components. This software enables engineers to create digital blueprints for parts, which are then read and executed by precision machining tools. This level of automation not only increases efficiency and accuracy but also reduces waste, saving both time and resources.

Moreover, advancements in materials science are also influencing precision machining. The development of new, more durable, and lightweight materials has opened up new possibilities for machining processes and the types of parts that can be produced.

In addition, the rise of Industry 4.0—wherein automation and data exchange are central in manufacturing technologies—has led to the emergence of smart factories. In these environments, interconnected machinery and systems communicate and make decisions autonomously, further enhancing precision and efficiency.

At TMC Technologies, we are always at the forefront of these technological advancements. Our commitment to innovation enables us to continually improve our processes and services, ensuring we consistently deliver high-quality, precision-machined parts that meet our clients’ evolving needs. As we look to the future, we are excited about the potential of emerging technologies like AI and machine learning to further revolutionize precision machining parts manufacturing.

Conclusion: The Art of Precision Machining Parts Manufacturing

The Importance of Precision Machining in Today’s World

In the world of manufacturing, precision is not just a luxury, it’s a necessity. From the cars we drive to the appliances we use daily, high precision parts are fundamental to the function and longevity of these products. In sectors such as the automotive, aerospace, and medical industries, the demand for exact and flawless parts is non-negotiable. Inaccuracies in a machined part can lead to catastrophic failures, making the role of precision machining critical in maintaining safety and quality standards.

Moreover, the economic efficiency brought about by precision machining cannot be overlooked. By using computer-aided machinery, precision machining not only ensures a higher degree of accuracy but also reduces material waste and saves time. The ability to produce consistent, repeatable results at high volumes is a game-changer for manufacturers, allowing them to meet the growing demands of their industries without compromising on quality.

TMC Technologies’ Contribution to the Precision Machining Industry

Amidst the vast landscape of precision machining, TMC Technologies has carved out a distinct and respected space. With over 30 years of experience, they have demonstrated an unwavering commitment to delivering top-notch precision machining services, underpinned by their attention to detail and rigorous quality control checks.

By leveraging state-of-the-art automated tools and technology, TMC Technologies offers a versatile range of precision machining capabilities. Their proficiency extends to a plethora of materials, including aluminum alloys, brass, titanium, stainless steel, and plastics, further broadening their reach and utility in the manufacturing sector.

TMC Technologies’ expertise in CNC lathe parts has proven particularly valuable for industrial machinery manufacturers. The company’s ability to design and fabricate custom applications provides a unique selling proposition, addressing the pain points of businesses seeking reliable suppliers and high-quality components.

The company’s continuous pursuit of technological advancement and innovation, coupled with their dedication to customer satisfaction, has positioned TMC Technologies as a trusted and forward-thinking leader in the precision machining parts manufacturing industry.

In conclusion, precision machining is an art form where accuracy, consistency, and efficiency intersect. TMC Technologies, through its unwavering commitment to quality and innovation, stands as a testament to this. As we move forward into a future where precision is paramount, the work of companies like TMC Technologies will continue to play a pivotal role in driving the manufacturing industry forward.