Introduction to Precision Machining

When it comes to the manufacturing process, the devil is in the detail, and precision machining is the angel that tames this devil. Precision machining is a beautifully orchestrated symphony of advanced technology, innovation, and meticulous attention to detail, ensuring the production of high-quality, accurate components. It’s a process where computerized machine tools, CAD and CAM systems, multi-axis CNC machining, and specific techniques like Swiss machining harmonize to create parts that match the most demanding and exacting specifications.

For businesses in need of CNC lathe parts, a keen understanding of precision machining is crucial. The process is the backbone of many industries, including aerospace, defense, automotive, medical, and oil field technology. It’s the key to achieving efficiency, accuracy, and the longevity of machinery.

One of the key players making waves in this field is TMC Technologies. With a commitment to delivering top-notch precision machining services, TMC Technologies has carved a niche for itself in the industry. But what exactly do they offer, and how can they address your needs for precision machining near you? Let’s dive in and unearth these local gems.

Understanding the Cost of Precision Machining

Cracking the code of precision machining costs can often feel like deciphering a complex blueprint. But fear not, we’re here to untangle the intricate web of machining service costs, from hourly rates to manual and CNC machining expenses, and even how to calculate these costs.

How Much Does Machining Cost Per Hour?

Machining centers, the heart of any manufacturing operation, come with an array of costs attached, one of which is the hourly cost of operation. This cost varies depending on the complexity of the machining process. For instance, 3-axis machining typically costs between $35 – $40 per hour. This cost takes into account various factors including machine depreciation, maintenance, energy consumption, and labor.

How Much Does CNC Machining Cost Per Hour?

For those exploring CNC machining near me, it is essential to understand its cost structure. CNC machining, particularly multi-axis machining, is a more complex process and thus comes with a higher price tag. The hourly rates for 4-axis or 5-axis CNC machining can range from $75 – $120. This cost also reflects the level of finish, whether rough or smooth, and the cost of materials used.

How Much Does Manual Machining Cost?

While CNC machining dominates the industry with its precision and automation, manual machining still has a place in many manufacturing operations. If we compare the hourly costs, manual machining services can cost around $40 per hour, while CNC machining services for a 3-axis machine can cost approximately double that rate. As the complexity of the requirements increases, so does the cost.

How to Calculate Machining Cost?

Determining the machining cost of a component is a straightforward process. Essentially, it involves dividing the total expenditure associated with the machining process by the number of hours required to manufacture the part. This gives you the machining cost per piece. Understanding this cost is crucial for businesses to accurately calculate project costs, set pricing for products or services, and ultimately enhance profitability.

In conclusion, understanding the cost associated with precision machining services, both in terms of the initial investment and ongoing operation, is a vital step in making informed decisions that align with your business goals. Whether it’s a search for a precision machine shop near me or assessing the cost-efficiency of your current operations, this knowledge empowers you to strike the right balance between cost and performance.

The Unique Selling Proposition of TMC Technologies

When it comes to precision machining, one name stands out from the crowd – TMC Technologies. But what is it that sets TMC Technologies apart in this competitive landscape? It all boils down to two key elements: their commitment to producing high-quality CNC lathe parts and their extensive range of additional machining services.

High-Quality CNC Lathe Parts

In the world of industrial machinery, the quality of components can make or break the efficiency and longevity of your operations. TMC Technologies understands this well, and their unwavering dedication to precision and quality is evident in every CNC lathe part they produce.

Each part is crafted to meet stringent quality standards and precise specifications, making them a testament to TMC Technologies’ attention to detail and accuracy. The company’s capabilities are not limited by quantities either. Whether you require prototype parts or a full production run, you can rest assured that the output will always be of the highest quality, competitively priced, and delivered promptly.

Additional Machining Services: Tool Design and Fabrication

While the production of top-tier CNC lathe parts is TMC Technologies’ specialty, their offerings don’t stop there. They are also well-equipped to provide a comprehensive suite of CNC machine shop services. These include CNC milling and turning, CNC sawing and drilling, CNC grinding and lapping, CNC threading and tapping, and many more.

For those one-of-a-kind applications that demand a unique solution, TMC Technologies steps up with their tool design and fabrication services. Their team of experts will work closely with you to understand your specific needs, creating and delivering components that are not just of exceptional quality but also tailored to your exact requirements.

In essence, partnering with TMC Technologies means you’re not just getting a supplier—you’re gaining a dedicated team that’s committed to your success. Their unique selling proposition lies in their ability to combine advanced machining capabilities with a customer-centric approach, making them an ideal choice for any business in search of precision machining near them.

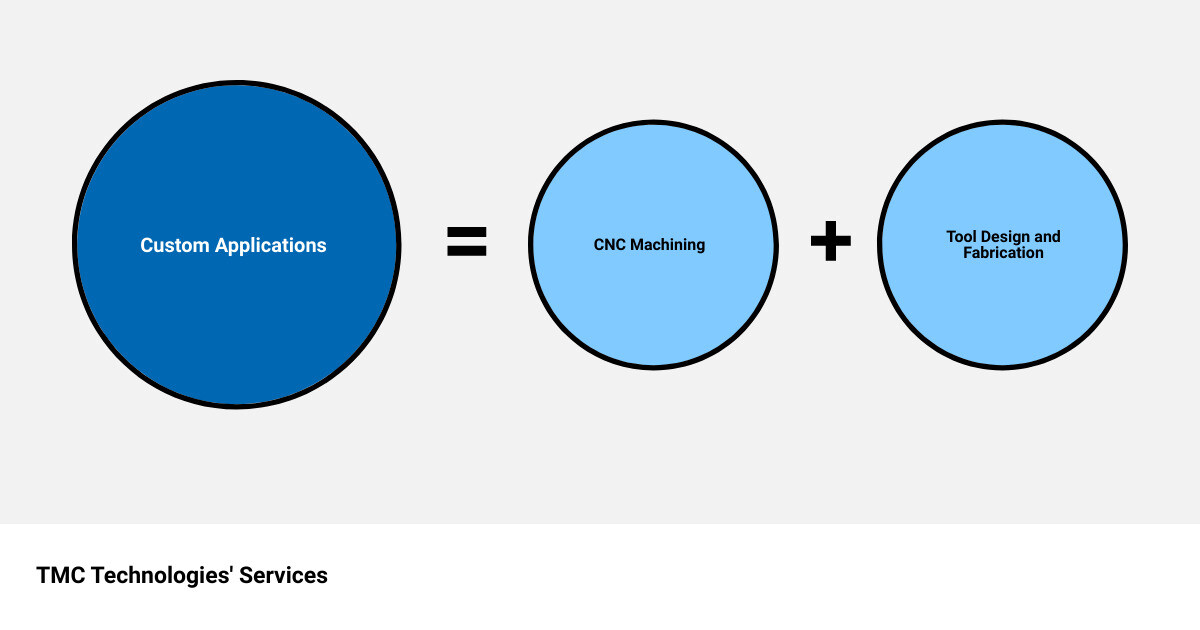

Exploring the Services of TMC Technologies

When it comes to precision machining, finding a provider that offers a comprehensive suite of services is key. TMC Technologies is one such company, with a portfolio that includes CNC machining, tool design and fabrication, and custom applications. Let’s delve into these services to better appreciate the high-quality solutions they can deliver.

CNC Machining

CNC, or Computer Numerical Control, machines are the backbone of TMC Technologies’ manufacturing process. These machines are fed with digital blueprints containing the exact specifications for each part, ensuring repeatability and accuracy for each piece, be it a one-off prototype or a batch of thousands.

With the use of both three-axis and four-axis CNC milling machines, TMC Technologies can produce complex shapes and mill from any angle. The advantage of CNC machines is not just their speed but also their precision. They make fewer errors compared to human-operated machines, which translates to time and cost savings for you.

Tool Design and Fabrication

In addition to their machining capabilities, TMC Technologies also excels in tool design and fabrication. This service emphasizes their commitment to providing tailored solutions for their clients. By using advanced engineering software like Master Cam, Gibbs Cam, and Solid Works, they can create custom tool designs to meet specific customer requirements.

The ability to customize tools and parts is what sets TMC Technologies apart in the precision machining industry. It means that whatever your needs, they have the expertise and the technology to deliver.

Custom Applications

Precision machining is not a one-size-fits-all solution. Each industry and each project have unique requirements that demand a tailored approach. At TMC Technologies, they understand this and extend their artistry of precision machining to the design and fabrication of tools for custom applications.

From the medical industry to the aerospace sector, TMC Technologies can create custom tools and parts that meet the stringent standards of these high-demand sectors. This capability ensures that no matter your industry or your project’s complexity, TMC Technologies has got you covered.

In conclusion, TMC Technologies offers a comprehensive suite of services to meet your precision machining needs. Their CNC machining capabilities, combined with their tool design and fabrication services, ensure that they can deliver high-quality, custom solutions for your projects. Whether you’re looking for a one-off prototype or a batch of thousands, TMC Technologies should be your go-to choice for ‘precision machining near me’.

The Importance of Certifications in Precision Machining

When it comes to precision machining, certifications are not just pieces of paper. They are a testament to a company’s commitment to quality, accuracy, and reliability. They ensure that the company adheres to international standards and best practices, giving you confidence in the performance and longevity of the components you receive.

ISO 9001:2008 Certification

ISO 9001:2008 certification is a globally recognized standard that highlights a company’s dedication to maintaining quality in their products and services. It shows that the company has a well-defined quality management system in place and consistently meets customer and regulatory requirements. Milwaukee Precision Machining, for example, is a state-of-the-art ISO 9001:2008 certified machine shop, assuring you of their commitment to quality.

AS9100D & ISO 9001-2015 Certification

The AS9100D & ISO 9001-2015 certification is of paramount importance in precision machining, particularly in industries like aerospace where safety and quality cannot be compromised. In fact, compliance with AS9100D is a prerequisite for doing business in the aerospace sector. Companies like Portland Precision and TMC Technologies proudly hold the AS9100D & ISO 9001-2015 certification, underscoring their commitment to meeting the rigorous safety, reliability, and quality standards of the aerospace industry.

ITAR Registration

The International Traffic in Arms Regulations (ITAR) registration is another crucial certification for precision machining companies, particularly those involved in defense-related manufacturing. ITAR registration indicates that the company is authorized to work with defense-related articles and services, ensuring compliance with U.S. export laws. With ITAR registration, companies like Portland Precision and TMC Technologies can confidently serve clients in the defense sector, meeting their precise specifications while adhering to the necessary regulations.

In conclusion, certifications in precision machining are not just about compliance. They are a reflection of a company’s commitment to quality, accuracy, reliability, and regulatory adherence. They provide the assurance that your ‘precision machining near me’ search will yield a partner capable of delivering high-quality, custom components that meet your exact requirements.

The Role of Precision Machining in Various Industries

The silent workhorse of the manufacturing world, precision machining, plays a pivotal role across a broad spectrum of industries. This critical process ensures the accurate and repeatable production of complex parts, regardless of industry requirements or geometries.

Aerospace Industry

In the aerospace sector, precision is not a luxury; it’s a prerequisite. The demand for impeccably crafted parts, capable of performing flawlessly under extreme conditions, is non-negotiable. Precision machines such as CNC and Swiss machines are integral to the manufacturing of complex aerospace parts. These parts require the highest levels of accuracy, often within ±0.0001 inches, to ensure safety and reliability. The influence of precision machining on the aerospace industry is profound, driving advancements in design and functionality, and facilitating adherence to strict international quality standards like AS9100.

Defense Industry

The defense sector, much like the aerospace industry, demands extraordinary precision and reliability. Precision machining is instrumental in the production of components that meet the rigorous standards of this industry. Companies like Portland Precision, a member of the Pacific Northwest Defense Coalition, have established themselves as trusted partners for defense-related precision machining projects, delivering high-quality, custom parts that meet and exceed client expectations.

Automotive Industry

Precision machining plays a crucial role in the automotive industry. As vehicles become more technologically advanced, the need for precision-machined parts increases. From engine components to intricate electronic systems, precision machining ensures the production of durable, high-performance parts that meet the demanding specifications of the automotive industry.

Medical Industry

In the medical field, precision and reliability can directly impact patient health, making precision machining essential. The production of medical devices and surgical tools, such as custom pins, leverages precision machines‘ ability to work with a variety of materials, including stainless steel, aluminum, and titanium. This enables the creation of durable, high-quality medical devices that can withstand the rigors of medical use.

Oil Field Technology Industry

In the oil field technology industry, precision machining aids in the manufacture of components that can endure harsh conditions and high pressures. The accuracy and reliability provided by precision machining ensure these components’ longevity and optimal performance.

In conclusion, the role of precision machining in various industries is pivotal. It’s the pillar on which each industry thrives, unlocking efficiency and setting new benchmarks for precision, efficiency, and quality. So, when you search for ‘precision machining near me’, ensure you choose a partner who understands the unique demands of your industry.

Conclusion: Why Choose TMC Technologies for Precision Machining Near You

When it comes to precision machining, TMC Technologies stands out as a forerunner in the industry. With over 30 years of experience in delivering top-notch precision machining services, TMC Technologies has built a stellar reputation that extends across a variety of industries, including aerospace, defense, and automotive among others.

TMC Technologies offers high precision CNC machining services, harnessing the power of advanced technologies such as 3D modeling and CNC turning to guarantee accuracy and superior workmanship. They are adept at delivering components that meet stringent tolerances, thanks to their state-of-the-art automated tools and highly skilled team.

But what truly distinguishes TMC Technologies from other providers is their unwavering commitment to quality. Each service undergoes rigorous quality control checks throughout the entire production process, ensuring that every component produced meets the highest standards of precision and accuracy. This commitment to quality is underscored by their AS9100D & ISO 9001-2015 certification and ITAR registration, providing further reassurance of their dedication to maintaining the highest industry standards.

Moreover, TMC Technologies offers short lead times without compromising on workmanship. Their services are not only efficient but also cost-effective, offering an optimal balance between quality and value. They work with a diverse range of materials, including aluminum alloys, brass, titanium, stainless steel, and plastics, and offer secondary operations such as heat treating to support their machining and manufacturing processes.

In a nutshell, if you’re searching for ‘precision machining near me‘, TMC Technologies is a name you can trust. Their expertise, advanced technology, and unwavering commitment to quality make them a reliable choice for manufacturing companies seeking high precision CNC machining services. Whether you need machining services for complex prototypes, finished parts, or volume production, TMC Technologies is ready to deliver with precision, efficiency, and excellence. So, when it’s time to decide on a precision machining partner, remember – TMC Technologies is just a call away!