CNC Lathe Live Tooling

At TMC Technologies, also known by our original name D&S Machine and Tool, we have embraced the evolution and challenges of precision manufacturing since our inception in 1989. Our journey has been marked by a steadfast commitment to exceeding customer expectations, not just meeting them. This pursuit of excellence has necessitated a deep dive into specialized services like CNC Lathe Live Tooling, a domain where we have carved out a niche for ourselves, especially here in Iowa.

Our comprehensive suite of services, spanning from design and 3D modeling to CNC turning, machining, and beyond, enables us to deliver superior quality products within the tightest timelines. This capability, combined with our diverse industry experience, positions us as a trusted partner for your manufacturing needs.

What is CNC Lathe Live Tooling?

CNC Lathe Live Tooling represents the pinnacle of efficiency in modern machining. It integrates rotating tools that perform milling, drilling, and tapping operations while the material is still clamped in the lathe. This innovative approach eliminates the need for multiple setups, thereby reducing production time and enhancing precision.

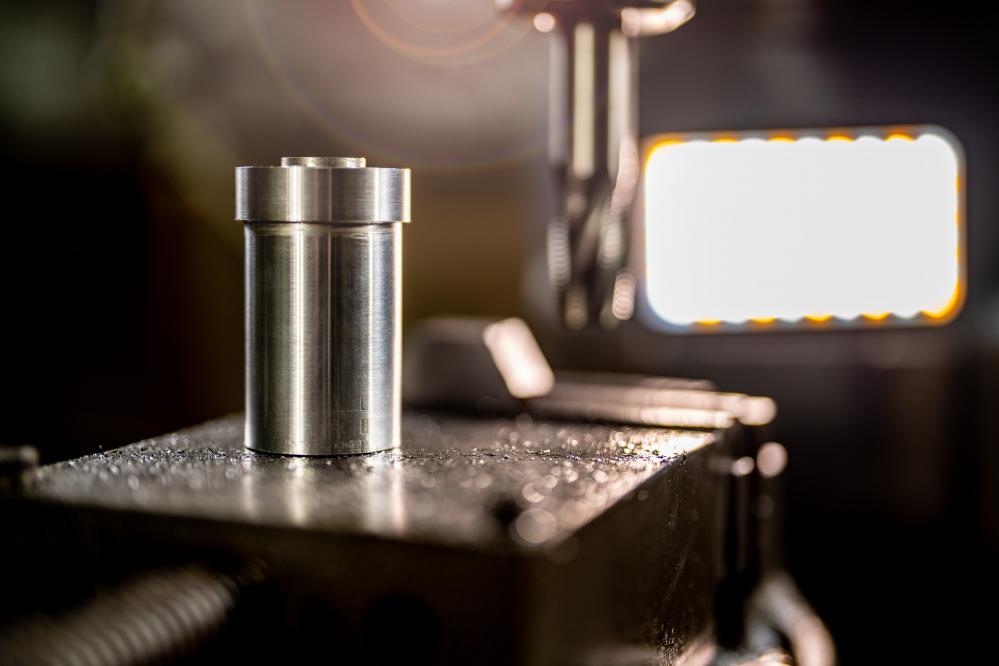

In the heart of Iowa, TMC Technologies has been at the forefront of adopting and perfecting this technology. Our state-of-the-art facilities are equipped with advanced CNC lathes that feature live tooling capabilities, allowing us to tackle complex projects with ease.

Advantages of CNC Lathe Live Tooling

Efficiency and Precision

One of the primary benefits of CNC Lathe Live Tooling is its unparalleled efficiency. By consolidating multiple manufacturing processes into a single setup, we significantly cut down on production time. Pair this with the inherent precision of CNC machining, and it’s clear why this method is a game-changer for industries requiring intricate components.

Versatility Across Industries

Thanks to its versatility, CNC Lathe Live Tooling Iowa has become indispensable across various sectors. Whether it’s agriculture, food processing, industrial manufacturing, firearms, or the aerospace and medical fields, our experience spans the gamut. This diversity in application underscores the adaptability and relevance of live tooling in today’s manufacturing landscape.

Our CNC Lathe Live Tooling Capabilities in Iowa

State-of-the-Art Equipment

TMC Technologies prides itself on housing an array of advanced CNC lathes designed to accommodate live tooling. This includes multi-axis machines capable of executing complex operations with high precision. Our investment in cutting-edge technology ensures we remain competitive and can deliver the best possible outcomes for our clients.

Customized Solutions

Understanding that each project has its unique challenges, we specialize in offering customized solutions. Our team works closely with clients to develop and execute plans that meet specific requirements. This collaborative approach is fundamental to our mission of exceeding expectations through service, quality, and innovation.

Why Choose TMC Technologies for CNC Lathe Live Tooling in Iowa

Choosing TMC Technologies means partnering with a company that brings decades of experience, a commitment to quality, and a comprehensive service offering to the table. Our track record speaks for itself, with a history of successfully delivered projects across a broad spectrum of industries.

Moreover, our strategic location in Carol, Iowa, enhances our ability to serve not just the local market but clients across the country. Our facilities are designed to support both large-scale production runs and more bespoke, intricate projects, making us a versatile partner for your manufacturing needs.

Our Collaborative Approach to Projects

At the heart of our operation is a deeply ingrained philosophy of collaboration. We believe that the best results stem from a partnership approach, where open communication and mutual respect drive the project forward. This ethos is evident in every interaction, from the initial consultation to the final delivery of your project.

Our team is not just a group of technicians and engineers; we’re problem solvers dedicated to finding the most efficient and effective solutions for your needs. By choosing TMC Technologies, you’re not just getting a service provider; you’re gaining a partner committed to your success.

Get in Touch with TMC Technologies

Ready to discuss your next project or just looking to learn more about CNC Lathe Live Tooling Iowa? Reach out to us at TMC Technologies. You can contact us directly through our email at [email protected] or give us a call at 712-792-5512. Our team is ready to bring our expertise, capabilities, and passion for precision manufacturing to your next project.

Located at 2047 Industrial Park Road, Carol, Iowa, we invite you to visit us or arrange a tour of our facilities. Discover first-hand how our commitment to quality, collaboration, and customer service sets us apart in the world of precision manufacturing.

What is live tooling in CNC lathe?

Live tooling in a CNC lathe is a feature that allows rotating tools, like mills and drills, to operate while the workpiece remains fixed in the chuck. Imagine being able to perform both turning and milling operations without having to reposition the workpiece. This not only streamlines the production process but significantly enhances precision by reducing setup times and potential errors from multiple setups. At TMC Technologies, we’ve seen firsthand how this integration can transform complex manufacturing projects, making what was once considered challenging or even impossible tasks, quite manageable and efficient.

What is a CNC lathe sometimes called?

A CNC lathe is sometimes referred to as a CNC turning center. The term “turning center” often denotes a machine that includes additional capabilities beyond simple turning, such as milling and drilling operations which are common in live tooling setups. This distinction is crucial in understanding the full capabilities of a CNC lathe. At TMC Technologies, when we discuss our CNC lathes, we’re often talking about sophisticated machinery capable of executing a comprehensive range of tasks, all designed to meet and exceed the complex requirements of our diverse clientele.

What are the parts of a CNC machine?

The primary components of a CNC machine include the control panel, worktable, cutting tools, tool turret, spindle, and chuck. Each part plays a vital role in the machine’s operation. The control panel is the brain, allowing for programming and control of the machine. The worktable and chuck hold the workpiece in place, while the cutting tools perform the actual machining operations. The spindle provides the necessary speed, and the tool turret holds various tools, allowing for quick changes between operations. At TMC Technologies, understanding and maintaining these components is part of our daily routine, ensuring peak performance and precision in every project we undertake.

Which tool is used in a CNC machine?

In a CNC machine, a variety of tools can be used depending on the operation being performed. For turning operations, we use lathe tools that can cut in various dimensions and profiles. For milling, end mills are employed to produce complex shapes and surfaces. Drills are used for making holes, and taps for threading. One of the beauties of CNC machining, especially with live tooling, is the versatility in the types of operations we can perform by simply changing the tooling. Our expertise at TMC Technologies enables us to select the optimal tool for each job, ensuring efficiency and precision in our manufacturing processes.

Why is CNC lathe live tooling advantageous for precision manufacturing?

CNC lathe live tooling is advantageous for precision manufacturing due to its ability to combine multiple operations into a single setup. This consolidation not only saves time but also minimizes the potential for error by eliminating the need to move the workpiece across different machines. At TMC Technologies, using live tooling means we can produce complex parts with intricate features faster and with incredibly high precision. This capability is particularly beneficial in industries where component accuracy is critical, such as aerospace, medical, and defense.

How does TMC Technologies ensure quality in its CNC machining processes?

At TMC Technologies, quality assurance is embedded in every step of our CNC machining processes. We start by meticulously planning each project, considering the best tools and strategies for the job. Our state-of-the-art machines are regularly maintained and calibrated, guaranteeing optimal performance. Furthermore, our skilled technicians and engineers monitor each project closely, employing both in-process inspections and comprehensive final checks to ensure the finished product meets our high standards and, more importantly, our clients’ expectations. This relentless commitment to quality is a cornerstone of our operation, setting us apart in the field of precision manufacturing.

Resources

- Tooling U-SME – CNC Lathe Live Tooling – Learn more about CNC lathe live tooling and its applications in precision manufacturing.

- Modern Machine Shop – Live Tooling in CNC Turned Parts – Explore the benefits and capabilities of live tooling in CNC machining processes.

- NPTEL – CNC Machines and Control – Dive into the principles and operations of CNC machines, including live tooling functionalities.

- Haas Automation – Live Tooling on Haas CNC Lathes – Discover how live tooling enhances the capabilities of Haas CNC lathes for advanced machining tasks.