In our increasingly digital world, the role and importance of precision machines and equipment cannot be overstated. These advanced tools, which include everything from high-precision CNC lathes to multi-axis machining centers, have revolutionized countless industries, making it possible to create intricate parts and components with unparalleled accuracy and efficiency.

The evolution of precision machines and equipment has been driven by the growing demand for high-quality, consistent, and precise parts across a wide range of sectors, from aerospace to electronics to the medical industry and beyond. These industries require parts that meet exacting standards, which can only be delivered by advanced precision machines and equipment.

For a manufacturing company like yours, the quality and reliability of your machinery is paramount, and the efficiency and longevity of your machines can be directly linked to the precision of the parts they contain. That’s where precision machines and equipment come into play. By using these advanced tools, you can ensure the highest level of accuracy and consistency in your parts, enhancing the performance and lifespan of your machines.

In this article, we’ll delve deeper into the world of precision machines and equipment, exploring their role, importance, and the benefits they bring to various industries. Specifically, we will highlight how TMC Technologies, a leader in precision machining, provides top-tier quality CNC lathe parts and additional machining services for custom applications, helping businesses like yours overcome challenges and maximize efficiency. So, let’s get started on this journey to unlock efficiency through the rise of precision machines and equipment.

Understanding Precision Machines: Definition and Examples

In the labyrinth of industrial machinery, precision machines are the compass guiding us towards unprecedented accuracy and efficiency. But what exactly is a precision machine? And how do high precision machines achieve those tight tolerances?

What is a Precision Machine?

A precision machine is a high-precision machine tool used to achieve extreme levels of accuracy. This advanced tool is the cornerstone of precision manufacturing, which includes processes like grinding, honing, lapping, and polishing. Precision machines come in various forms such as lathes, grinders, CNC milling machines, cutting tools like saws and drill presses, and even high-speed robotics. These machines are designed to produce parts with intricate or complex geometries to a high degree of repeatability and accuracy.

High Precision Machines: Achieving Tight Tolerances

High precision machines take the concept of precision to the next level. They are at the heart of high precision machining, a process that produces metal components to very tight tolerances. This process leverages state-of-the-art CNC machines or screw machines that can easily handle the tight tolerances required for high-precision components. These high precision machines are the secret ingredient in the recipe for creating parts with tolerances as small as ±0.0001”.

Examples of Precision Manufacturing Processes

Precision manufacturing is like an orchestra, with each process playing its part to create a harmonious symphony of precision and quality. Examples of precision manufacturing processes include grinding, honing (which includes superfinishing), lapping, and polishing.

Grinding, for instance, is a machining process that uses an abrasive wheel to remove material from a workpiece, achieving a smooth finish and precise dimensions. Honing, on the other hand, is a process used to improve the geometric form of a surface and the surface texture. Lapping is a process in which two surfaces are rubbed together with an abrasive between them to achieve an extremely flat surface.

These processes, facilitated by precision machines, are integral in various industries, including aerospace, electronics, and medical industries, where the demand for precision is non-negotiable.

In a world where precision and efficiency are paramount, understanding precision machines and their role in various manufacturing processes is crucial. This understanding is the first step towards unlocking efficiency and optimizing your manufacturing operations.

The Role of Precision Machinery in Various Industries

In the heart of every industry, lies the power of precision machinery. It’s a silent workhorse, tirelessly crafting complex geometries with astounding accuracy. The rise of precision machines and equipment has revolutionized industries such as aerospace, electronics, and medical, setting new standards for precision, efficiency, and quality.

Precision Machinery in Aerospace

In the aerospace industry, precision is not just a requirement but a pre-requisite. The need for impeccably crafted parts that perform flawlessly under extreme conditions is non-negotiable. Precision machines, such as CNC machines and Swiss machines, play a critical role in manufacturing complex aerospace parts. These parts demand the highest levels of accuracy, often within ±0.0001 inches, to ensure safety and reliability.

The integration of advanced technologies like multi-axis CNC machining and Swiss machining has elevated the manufacturing capabilities in the aerospace industry. The ability to work simultaneously across multiple axes not only improves precision but also reduces production time, resulting in more efficient manufacturing processes.

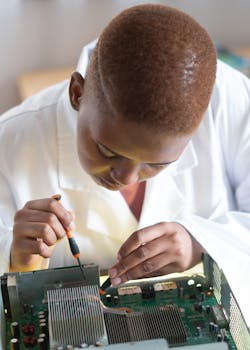

Precision Machinery in Electronics

Precision machinery’s role extends to the electronics industry, where intricate components are the norm. The miniaturization trend in electronics has led to an increased demand for parts with complex geometries and tight tolerances. Precision machines rise to this challenge, leveraging advanced tools to accurately shape materials, thereby contributing to the development of smaller, more efficient electronic devices.

With the aid of Computer Numerical Control (CNC) technology, precision machinery in the electronics industry achieves a high degree of repeatability. This ensures every produced component matches the original design specifications, contributing to the overall reliability and performance of electronic devices.

Precision Machinery in Medical Industry

In the medical industry, the stakes are even higher. Precision machining is essential in the production of medical devices and surgical tools, where precision and reliability can directly impact patient health. Swiss machining, known for its superior precision, is commonly used to manufacture complex medical parts such as custom pins and surgical tools.

The ability of precision machines to work with a variety of materials, including stainless steel, aluminum, and titanium, is a significant advantage in the medical industry. It allows for the creation of durable, high-quality medical devices that can withstand the rigors of medical use.

In conclusion, the role of precision machinery in various industries is pivotal. Its ability to deliver high precision and repeatability in manufacturing processes, regardless of the industry, is a testament to its importance. Precision machinery is not just a component of the manufacturing process; it is the pillar on which industries stand and thrive.

The Process of Precision Machining: From Design to Production

In a world where precision is paramount, the manufacturing process is undergoing a significant transformation. As industries strive for efficiency and accuracy, the role of precision machining cannot be overstated. This process takes manufacturing from concept to final product using computerized machine tools, CAD and CAM systems, multi-axis CNC machining, and specific techniques like Swiss machining.

The Role of Computerized Machine Tools in Precision Machining

Precision machining relies heavily on the use of advanced, computerized machine tools. These tools are designed to achieve demanding tolerances and create complex geometric cuts with a high degree of repeatability and accuracy. They provide the foundation for successful precision machining, ensuring parts are machined to the same tight tolerances repeatedly, regardless of the production volume.

The Use of CAD and CAM in CNC Machining

Computer-aided design (CAD) and computer-aided manufacturing (CAM) play a crucial role in the CNC machining process. Designers use CAD software to create digital design files, which are then translated into a CAM file. This file instructs the CNC equipment about the specific tools and processes to use. This complex and precise coordination between CAD and CAM systems ensures the final product meets the exact design specifications.

The Advantages of Multi-Axis CNC Machining

In the realm of precision machining, multi-axis CNC machining reigns supreme. Standard CNC tools typically work on three axes (X, Y, and Z). Still, multi-axis precision machining employs 4 to 5-axis machining for its superior capabilities. By incorporating additional axes, these machines can access a workpiece from virtually any direction, enabling greater precision and detail. This simultaneous operation also saves substantial setup time, reducing the potential for human error that may occur during part repositioning.

Swiss Machining: A High Precision CNC Machining Technique

Swiss machining, a specific type of CNC machining, is highly regarded for its precision capabilities. Unlike conventional machining where the tool moves towards the stock, Swiss machining brings the stock to the tool. This method allows for extreme accuracy, achieving tolerances within ±0.0001 inches. Swiss machines can also run unattended for extended periods, facilitating higher production volumes with less labor.

In conclusion, the process of precision machining is a beautifully choreographed dance of technology and innovation. From the use of advanced computerized tools and software to the application of specialized techniques like Swiss machining, it’s a testament to the incredible strides made in the manufacturing sector. As we continue to push the boundaries of what’s possible, the importance of precision machining in delivering high-quality, accurate components will only continue to grow.

Materials Commonly Used in Precision Machining

High-precision machines wouldn’t be of much use without the right materials to work with. Different materials present unique challenges and opportunities in the precision machining process, and choosing the right one for the job is critical to achieving the desired results. Let’s explore the materials commonly used in precision machining.

Aluminum in Precision Machining

Aluminum is a favorite material in precision machining due to its lightweight yet strong nature. A preferred choice for a multitude of industries, ranging from aerospace to electronics, aluminum is known for its excellent machinability. It stands up well to CNC machining processes, allowing for the precise fabrication of complex shapes. TMC Technologies, for instance, has extensive experience fabricating parts from aluminum alloys such as 6061-T6 and 7075-T7.

Brass in Precision Machining

Brass, a versatile alloy of copper and zinc, is another commonly used material in precision machining. Known for its corrosion resistance, low friction, and excellent heat conductivity, brass is often used in the manufacturing of gears, valves, and fittings. Its easy machinability also makes it a top pick for creating intricate designs and shapes.

Stainless Steel in Precision Machining

Stainless steel is a popular choice for precision machining due to its high strength, resistance to corrosion, and excellent heat resistance. Its ability to withstand extreme conditions makes it ideal for use in a wide variety of industries, including automotive, aerospace, and medical equipment manufacturing. Precision machining using stainless steel requires specialized tools and techniques to ensure accuracy, making the services of a knowledgeable manufacturer like McCormick Industries invaluable.

Titanium and Exotic Alloys in Precision Machining

When it comes to precision machining, the use of titanium and exotic alloys is on the rise. Titanium, known for its high strength-to-weight ratio and corrosion resistance, is commonly used in the aerospace and medical industries. Additionally, exotic alloys, which often include elements such as nickel, cobalt, and chromium, are used in applications that require exceptional performance under extreme conditions. These materials, however, require advanced precision machining techniques to maintain accuracy and prevent damage during the machining process.

In conclusion, precision machining involves a wide range of materials, each with its unique properties and machining requirements. By understanding the characteristics and applications of these materials, manufacturers can better select the right material for their precision machining needs, thereby ensuring the production of high-quality, accurate, and durable components.

TMC Technologies: A Leader in Precision Machining

In the world of precision machining, few companies stand out like TMC Technologies. With a dedication to quality and a commitment to unparalleled service, TMC Technologies has positioned itself as an industry leader, providing top-tier CNC lathe parts for a range of industrial applications.

TMC Technologies: Providing High-Quality CNC Lathe Parts

When it comes to sourcing CNC lathe parts, manufacturers seek a supplier who can ensure accuracy, longevity, and performance. TMC Technologies meets and exceeds these expectations by offering high-quality CNC lathe parts that are manufactured to precise specifications and meet stringent quality standards.

The company leverages its team of highly trained machinists and the most advanced CNC machines to ensure that all CNC lathe parts meet customers’ exact requirements. TMC Technologies understands that quality is of utmost importance when buying CNC lathe parts for replacement, and therefore, the company ensures that their components will enhance the accuracy and longevity of your industrial machinery, helping you avoid costly repairs or replacements down the line.

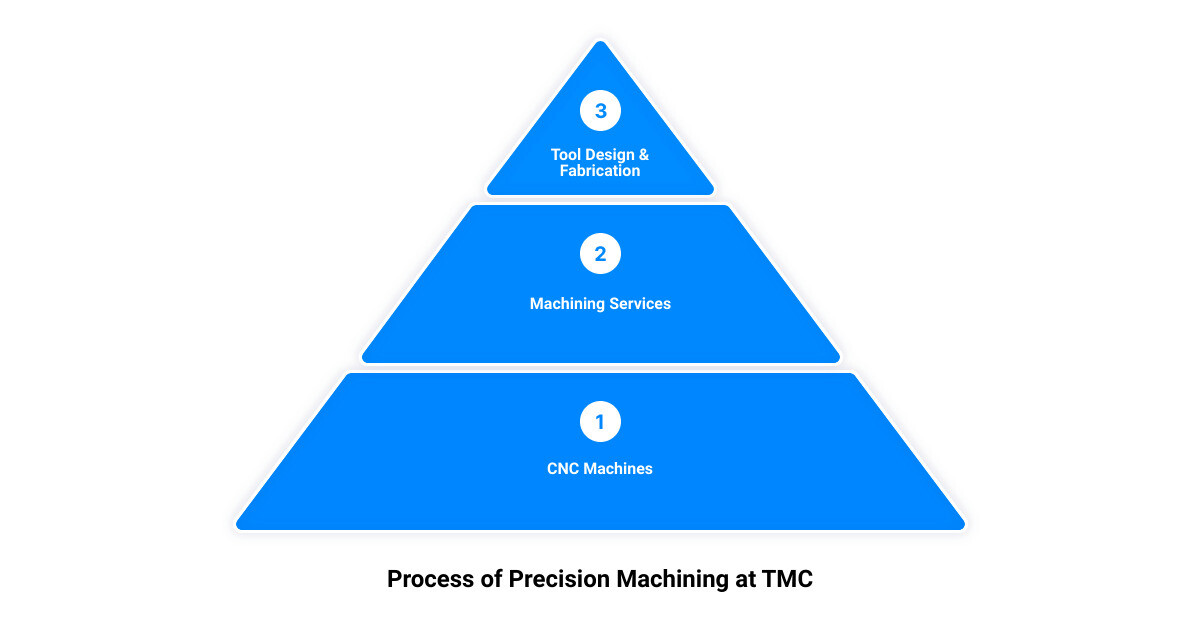

TMC Technologies: Offering Additional Machining Services

Beyond providing top-tier CNC lathe parts, TMC Technologies also offers a wide range of additional CNC machine shop services. These include CNC milling and turning, sawing and drilling, grinding and lapping, threading and tapping, and more. Each of these services is performed using state-of-the-art CNC equipment, ensuring the highest standards of quality and accuracy.

Moreover, TMC Technologies also provides additional services such as tool design and fabrication for custom applications. This means that you can get tailor-made solutions that fit your unique requirements and specifications, providing you with a competitive edge in your industry.

In conclusion, TMC Technologies is more than just a supplier of CNC lathe parts – it’s a comprehensive solution provider for all your precision machining needs. With its commitment to quality, advanced capabilities, and additional machining services, TMC Technologies is indeed a leader in the precision machining industry.

Conclusion: The Future of Precision Machines & Equipments

As we embrace the dawn of the Fourth Industrial Revolution, the importance of precision machines and equipment cannot be overstated. The role they play across various industries, from aerospace to electronics and the medical field, is not only critical but also transformative. Through precision machining, we can manufacture components with impressive accuracy, repeatability, and efficiency – a feat that is essential in an increasingly competitive manufacturing landscape.

The future of precision machines and equipment is undoubtedly bright and brimming with possibilities. We can anticipate further advancements in computerized machine tools, which are the backbone of precision machining. Alongside the evolution of CAD and CAM technologies, we can expect more sophisticated and efficient methods of creating digital design files and translating them into instructions for CNC machining equipment.

Moreover, the rise of multi-axis CNC machining and Swiss machining techniques is set to revolutionize how we manufacture intricate components. With capabilities to work on multiple axes simultaneously and bring the stock to the tool, these techniques are paving the way for even more precise and intricate machining processes.

As for the materials used in precision machining, we can foresee an increased demand for materials like aluminum, brass, stainless steel, and titanium. These materials’ durability and workability make them ideal for producing high-quality, long-lasting components.

In this promising future, TMC Technologies is positioned as a key player. With over 30 years of experience in precision machining services, state-of-the-art automated tools, and a commitment to quality, TMC Technologies is prepared to meet the evolving demands of the industry. Whether you need CNC lathe parts or additional machining services, TMC Technologies brings a wealth of expertise and a dedication to customer satisfaction to the table.

As we close the chapter on this exploration of precision machines and equipment, it’s clear that we are on the cusp of an exciting new era in manufacturing. The rise of precision machines and equipment is not just a trend; it’s a paradigm shift that is reshaping the way we design, produce, and utilize components across industries. As we navigate this dynamic landscape, choosing the right partner for your precision machining needs is crucial. With its proven track record and innovative solutions, TMC Technologies is ready to unlock efficiency and drive success for your business in the world of precision machining.