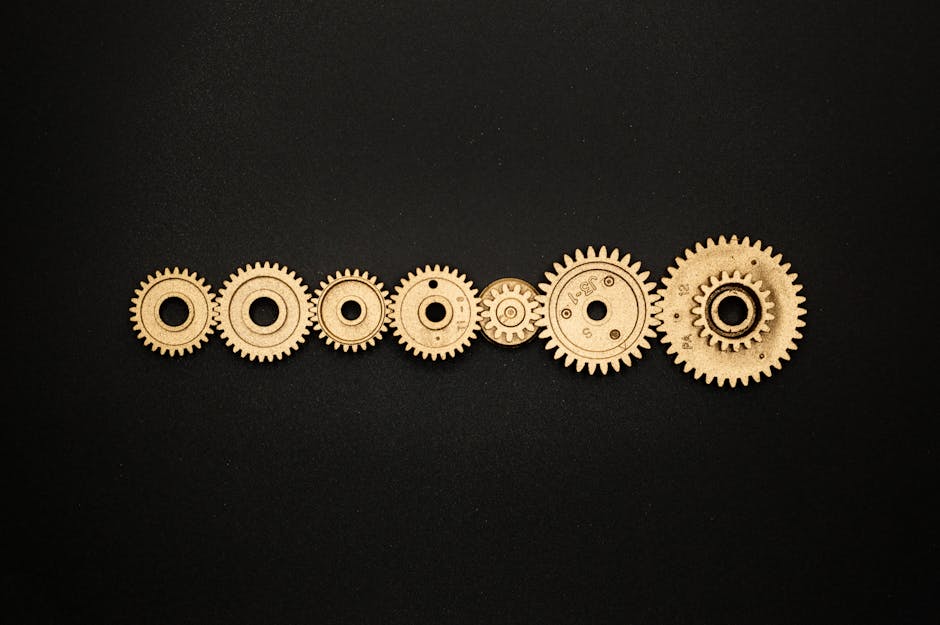

What are Turned Parts Anyway?

At a glance, turned parts are intricate components that are crafted down to the microns to fit into machines and equipment across various industries. They undergo a series of processes including the turning process wherein material gets cut away to result in a final product with utmost accuracy and precision. The process is primarily facilitated using a lathe machine, either manually controlled or a Computer Numerical Control (CNC) turning machine are employed for complex operations.

Now, why are we obsessed with turned parts at TMC Technologies? While ‘turned parts’ may sound like industrial jargon, it’s a term that holds immense significance to us. We understand that these components truly shape the functionality of your machinery. How? By relying on advanced machinery and meticulous processes, including a remarkable process known as CNC turning, we can repeatedly and accurately transform raw materials into these highly specific components.

As you delve deeper into turned parts and turning processes, you’ll discover the complex artistry involved in fashioning these crucial components. The secret is in harnessing the power of state-of-the-art machines and consistently trained technicians to deliver expertly crafted turned parts, acting as the heartbeat of various applications, contributing significantly to the efficiency and accuracy of your equipment. Decode the fascinating world of turned parts with us at TMC Technologies and discover how essential they are in powering your machinery.

Understanding the Turning Process in Manufacturing

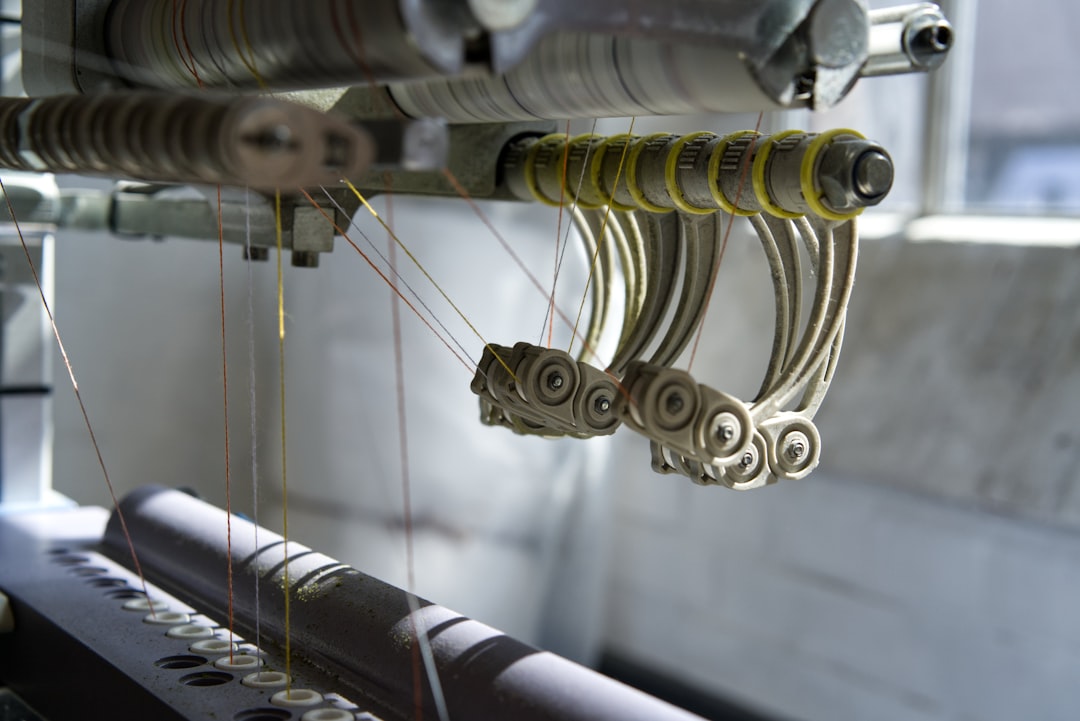

Turning, a fundamental machining process, plays a critical role in the creation of turned parts. It involves the use of a lathe, which spins the workpiece, while a cutting tool moves linearly, trimming away material to form the desired shape. This simple yet vital process is crucial in the production of a wide range of components used in various industries.

The Role of a Lathe in Turning

The lathe is the primary tool in the turning process. Its function is to rotate the workpiece at varying speeds while a cutting tool makes controlled movements to remove material along the diameter of the workpiece. This process, which can be executed manually or with a CNC (Computer Numerical Control) machine, results in the creation of cylindrically shaped components.

Whether it’s a simple manual lathe or an advanced CNC turning machine, the lathe’s ability to maintain precision and accuracy is of paramount importance. At TMC Technologies, we understand the role of the lathe in turning. We ensure our lathes are continually maintained and updated, guaranteeing the production of top-tier quality CNC lathe parts.

The Objective of Turning

The primary purpose of turning is to reduce the workpiece diameter to the desired size, creating a perfect cylindrical shape. This process is crucial in the production of a wide range of components, from simple bolts and screws to more complex parts like gear blanks and joint connectors.

But turning isn’t just about reducing diameter. It’s about achieving precision, consistency, and reliability. It’s about creating parts that fit perfectly into the bigger picture, ensuring the smooth operation of the overall machine.

At TMC Technologies, we take pride in our turning process, where we strive to achieve the highest degree of precision and consistency. We understand that every turned part plays a crucial role in our clients’ machinery, and we are committed to delivering parts that meet and exceed expectations.

So, in the intricate world of turned parts, understanding the turning process is the first step in appreciating the art and science behind these essential components. It’s about understanding how a simple process, when done with precision and attention to detail, can result in parts that power the world’s most complex machinery.

The Art of Precision in Turned Components

Taking a deeper dive into the fascinating world of turned parts, it’s time to uncover the art of precision that goes into manufacturing each component.

What Makes a Component Precision Turned

Precision is the cornerstone of quality when it comes to turned components. A precision turned component is one that has been expertly crafted using computer numerical control (CNC) turning, a process that ensures the utmost accuracy and consistency. This results in components that are meticulously manufactured down to the last micron (TMC Technologies).

CNC turning is what sets precision turned components apart. The process involves pre-programmed instructions that dictate the exact paths and directions the machinery should take. Through this method, excess material can be drastically reduced, resulting in cost-effective components that don’t compromise on quality (Screw Machine Products).

The Importance of Tight Tolerances in Precision Turned Parts

The precision of turned parts is largely determined by how tight the tolerances are. Tolerances refer to the allowable variation in the size and geometry of a part. In other words, it’s the wiggle room manufacturers have when creating a part. The tighter the tolerance, the less wiggle room there is, and the higher the precision of the part.

Tight tolerances are essential in industries that demand high-quality parts. They contribute significantly to the efficiency and accuracy of the machines that these parts are a part of (TMC Technologies). For example, in the aerospace industry, where precision is crucial for safety and performance, components with tight tolerances are required.

At TMC Technologies, we understand the importance of tight tolerances in the manufacture of turned parts. Our state-of-the-art CNC machines and highly trained technicians ensure that every component we produce meets the stringent tolerance range of 0.001mm-0.005mm. This ensures high precision in every component, reducing waste and saving costs for our customers.

In the next section, we’ll delve into the common materials used in turning parts and the role these materials play in the quality of turned components. Stay tuned to continue unveiling the intricate world of turned parts.

The Materials Used in Turning Parts

In the art of creating turned parts, the choice of material is just as important as the process itself. The material used can greatly impact the performance, durability, and overall quality of the final product. Let’s explore the common materials used in turning parts and understand how material selection influences the quality of turned components.

Common Materials for Turned Parts

A variety of materials can be used for creating turned parts, with each offering its unique properties and advantages. Common materials include aluminium, steel, stainless steel, and plastic polymers. Some of the more robust components may even be crafted from super alloys and brass.

The choice of material often depends on the desired properties of the final product. For instance, aluminium is known for its light weight and excellent thermal conductivity, making it a popular choice for aerospace and automotive applications. Steel, on the other hand, offers superior strength and durability, making it ideal for heavy-duty industrial machinery.

The Role of Material Selection in the Quality of Turned Parts

Selecting the right material for a particular part is a critical decision in the precision turning process. Different materials offer different properties such as tensile strength, corrosion resistance, and thermal conductivity. The right material can greatly enhance the performance and lifespan of the component.

At TMC Technologies, we carefully select the best material for each project, ensuring the final product meets the exact requirements of our customers. Our team of experts understands the subtleties of working with a wide range of materials, ensuring each component is crafted to perfection.

Material selection is not just about picking the strongest or most durable option. It’s about understanding the specific needs of the application and choosing a material that provides the best balance of strength, durability, cost, and performance.

In conclusion, the material used in creating turned parts plays a pivotal role in determining the quality, performance, and longevity of the final product. At TMC Technologies, we take material selection seriously, utilizing our expertise to deliver top-tier quality parts that meet and exceed our customers’ expectations.

In the next section, we’ll explore the wide range of applications for turned parts in various industries. Stay tuned to continue our journey through the fascinating world of turned parts.

The Applications of Turned Parts in Various Industries

Stepping into the real-world application of turned parts, we find a multitude of industries that rely heavily on these meticulously crafted components. From aerospace to defense, and medical to telecommunications, turned parts play a pivotal role in powering industries and driving innovation.

Aerospace and Defense Applications

The precision of turned parts is not just a luxury but a necessity in the aerospace and defense industries. The intricate shapes and geometries of these components, such as screws, fasteners, connector pins, and shafts, ensure the functionality and safety of aircrafts and spacecrafts. As a trusted partner in aerospace CNC machining, TMC Technologies adheres to the industry’s stringent safety and precision standards, often crafting turned parts with a staggering accuracy within ±0.0001 inches.

In the defense sector, the precision and durability of turned components are paramount. These parts are often exposed to extreme conditions and need to perform consistently without fail. Our commitment to quality and precision ensures that the turned parts we provide can withstand the rigors of defense applications.

Medical and Telecommunications Applications

Precision turning also plays a critical role in the medical industry. Surgical tools, medical devices, and custom pins are just a few examples of essential medical components created through precision turning. The high degree of accuracy ensures the safety and effectiveness of these devices, which directly impact patient health.

In the telecommunications industry, turned parts like connector bodies and fittings are integral to the functionality of communication devices. The intricate components crafted through precision turning contribute to the development of more efficient electronic devices. Our precision turning operations ensure a high degree of repeatability, meaning every component we produce matches the original design specifications. This contributes to the reliability and performance of telecommunication devices.

At TMC Technologies, our precision turned parts are crafted with the highest degree of accuracy, ensuring consistent performance across various industries. Whether it’s a component for an aircraft, a surgical tool, or a communication device, we deliver top-notch precision turning services, catering to your specific industry needs.

In the next section, we’ll delve into the benefits of CNC turning in the production of turned parts. Stay with us as we continue to unmask the art of turned parts.

The Benefits of CNC Turning in the Production of Turned Parts

In manufacturing, efficiency is king. CNC turning, a fundamental process in producing turned parts, has revolutionized the industry, offering several tangible benefits. Let’s explore how CNC turning can elevate your production process.

The Cost-Effectiveness of CNC Turning

A significant advantage of using CNC turning in the production of turned parts is its cost-effectiveness. CNC machines operate based on pre-programmed instructions, allowing for precise paths and directions during the machining process. This precision drastically reduces excess material, resulting in reduced costs and more competitive pricing for the end product.

Moreover, the consistency achieved with CNC machines boosts uniformity and speed in the production process. Unlike manual operations, CNC machines don’t tire or need breaks. This means they can run continuously, barring the need for occasional repairs, thereby assuring continuous output and a more efficient production process.

In the long run, the use of CNC turned components can lower the risk of defective components and premature mechanical failures, helping you save on potential repair and maintenance costs.

The Precision and Accuracy Achieved Through CNC Turning

The precision and accuracy of CNC turning are unparalleled. CNC machines, like the ones we use at TMC Technologies, ensure that every part made is exactly like the one before it, accurate down to a few micrometers.

This high level of accuracy is critical in industries where even the smallest error can lead to significant consequences. For example, in the aerospace industry, a slight malfunction can lead to catastrophic results. Therefore, the high precision and consistency offered by CNC turning are essential in ensuring components fit accurately, preventing part failure and consequential loss of property.

The precision of CNC turning also enhances user-friendliness and safety ratings of the machined parts, further contributing to cost savings by reducing the likelihood of workplace accidents.

At TMC Technologies, we pride ourselves on the precision and accuracy we achieve through our state-of-the-art CNC machines. We understand the importance of precision in your industries and strive to provide the highest quality, precision CNC turned components to meet those needs.

In conclusion, CNC turning offers numerous benefits in the production of turned parts, including cost-effectiveness, precision, and accuracy. In the next section, we’ll discuss our role at TMC Technologies in turned parts. We invite you to continue on this journey as we delve deeper into the intricate world of turned parts.

The Role of TMC Technologies in the World of Turned Parts

At TMC Technologies, we understand the pivotal role of turned parts in maintaining the smooth operation and enhancing the longevity of machinery across diverse industries. Our mission is to provide top-tier quality turned parts and precision turning services that meet and exceed industry standards.

TMC Technologies’ Commitment to Quality and Precision

Our commitment to delivering high-quality turned parts is deeply ingrained in our day-to-day operations. We believe that quality and precision aren’t just about getting the job done, but about understanding our clients’ specific needs and delivering tailored solutions. Each turned part we produce undergoes rigorous quality checks to ensure it meets the most stringent specifications.

Our unwavering commitment to quality, precision, and accuracy has earned us the trust of numerous industries, including Agriculture, Food Processing, Industrial, Firearms, and Medical/Military/Aerospace. We strive to not just meet, but exceed industry standards, ensuring top-tier quality components for our clients.

The Unique Services Offered by TMC Technologies

In addition to providing precision turned parts, we offer a broad array of services, including heat treating, light fabrication/assembly, and custom applications. Our ability to provide a fast turnaround time ensures your production schedule stays on track.

We leverage state-of-the-art automated tools and our team’s expertise to deliver services efficiently and cost-effectively. From tool design and fabrication for custom applications to advanced machining components manufacturing, we meet the diverse and evolving needs of our clients.

In addition to our core services, we offer precision turning services and custom CNC fabrication, ensuring a comprehensive solution for our clients’ manufacturing needs.

At TMC Technologies, we believe in forming partnerships with our clients to achieve common goals and drive success. Your success is our success, and we are committed to making your vision a reality. If you’re in need of top-tier quality components, remember to weigh the benefits of selecting a reliable manufacturer. At TMC Technologies, we’re always ready to deliver excellence, every step of the way.

Join us in the next section as we conclude our journey through the intricate world of turned parts and look towards the future of precision turning.

Conclusion: The Future of Turned Parts and CNC Turning

The future of manufacturing lies in the intricate dance of machine learning, artificial intelligence, and automation, all harmonizing to create more efficient and precise manufacturing processes. For turned parts, this translates into even higher accuracy, improved surface finishes, and minimal errors.

The dawn of Industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, ushers in a new era of data-driven decision-making in CNC turning. These advancements will enable us at TMC Technologies to optimize our processes, reduce waste, and consistently deliver high-quality parts.

But while technology and automation will drive the future of CNC turning, let’s not forget the crucial role of skilled professionals. The synergy of human expertise and machines will continue to be the central pillar in precision machining.

At TMC Technologies, we don’t just watch this technological evolution from the sidelines – we’re active participants shaping it. Our unwavering commitment to continuous learning and investment in the latest technology places us at the forefront of these advancements.

The impact of micro machining services on various industries such as aerospace, medical, pharmaceutical, and electronics is profound. We are dedicated to delivering even more precise, efficient, and reliable micro machining services in the future.

Our commitment to quality, innovation, and customer satisfaction is unwavering. We are excited to embrace these advancements and continue delivering top-tier quality components and additional machining services for our clients.

The future of CNC turning and turned parts is indeed exciting, filled with boundless possibilities and opportunities. As your trusted partner in this journey, we at TMC Technologies pledge to continue our tradition of excellence as we meet the growing demand for precision CNC components.

We are not just part of this future – we are helping shape it. For more insights into CNC micro machining or to explore how our services can benefit your business, we invite you to visit our micro machining services page and our precision CNC components manufacturing page.

Thank you for considering TMC Technologies for your CNC machining needs. We look forward to working with you and helping you achieve your manufacturing goals.

In the intricate world of turned parts, the future is bright – and we can’t wait to explore it with you.