The manufacturing landscape is evolving faster than ever, and with it, the demand for more precise, efficient, and intricate parts is skyrocketing. Industries across the globe, from aerospace to medical, pharmaceutical to electronics, are in a race to develop superior products that stand out in the market. In the face of these challenges, one technology is making waves: micro machining services. In this article, we’ll dive into the world of micro machining, its significance in modern manufacturing, and how TMC Technologies, a leading provider of micro machining services, is helping businesses unlock precision in their operations.

Understanding the Concept of Micro Machining

If you think about the intricate and minuscule components used in medical implants, aerospace systems, or electronics, you might wonder about the technology behind their creation. The answer lies in micro machining, a process that uses advanced CNC machines to create components so small and detailed that high-power magnification is required to even see them.

What is Micro Machining?

Micro machining is a subset of CNC machining that involves cutting materials with tools smaller than the diameter of a human hair. It’s a highly specialized process that can produce parts with micron-level accuracy, repeatability, and superior surface finishes, something that no standard CNC machine can match. From creating miniature gears and shafts to intricate optical components, micro machining brings designs to life that would otherwise be impossible to achieve.

The Importance of Micro Machining in Modern Manufacturing

Micro machining is not just about creating small parts; it’s about pushing boundaries and breaking down the limits of traditional manufacturing processes. In an era where precision, speed, and efficiency are paramount, micro machining is becoming an essential tool for manufacturers. It allows for the production of highly complex and precise components quickly and efficiently, reducing production times and increasing the overall quality of the final product. Whether it’s for the medical field where the smallest details can impact a patient’s life or the aerospace industry where precision is non-negotiable, micro machining services are revolutionizing the way we manufacture.

Understanding the Concept of Micro Machining

In an era where precision and intricacy are paramount, micro machining services have emerged as a game-changer in the manufacturing industry. No longer limited by the constraints of traditional machining, businesses now have the ability to create complex and highly accurate components with dimensions in the micrometer range (less than 1 millimeter). But what exactly is micro machining, and why is it so vital in modern manufacturing?

What is Micro Machining?

Micro machining is a high-precision manufacturing process that involves the use of specialized tools such as micro-drills and micro-lathes to produce small and intricate parts. It is also known as mechanical micromachining and involves the use of mechanical micro tools with geometrically defined cutting edges in the subtractive fabrication of devices or features. The key aspect is that at least some of their dimensions fall within the micrometer range.

This technology is not just about miniaturizing parts; it’s about achieving a level of precision and accuracy that is unparalleled by traditional machining methods. The process is carried out by state-of-the-art CNC machines, which can handle the tight tolerances required for high-precision components. These machines can be adjusted more closely and easily, producing a flawless finish while maintaining the quality and accuracy of the component.

The Importance of Micro Machining in Modern Manufacturing

Micro machining is more than just a technological advancement; it’s a necessity in today’s manufacturing landscape. Industries such as automotive, aerospace, medical, and electronics heavily rely on micro machining services. Imagine the potential danger if an aerospace part fails mid-flight or a medical device suddenly stops working – these are scenarios that no business or consumer wants to encounter.

Furthermore, micro machining offers a level of control and accuracy that reduces waste by minimizing scrap from incorrect dimensions or damaged surfaces caused by manual machining. It also significantly reduces the possibility of human error, thereby enhancing quality control.

In the realm of modern manufacturing, micro machining is not just a fancy term; it’s an essential process that helps businesses meet exacting demands, ensure the longevity and reliability of their products, and stay competitive in a rapidly evolving market. As we delve deeper into the process of micro machining, you’ll discover how this technology is shaping the future of manufacturing.

The Process of Micro Machining

Unleashing the power of micro machining involves a precise and intricate process that is as much art as it is science. This advanced manufacturing method transforms raw materials into intricate parts with the help of computerized tools and advanced techniques such as micromilling, laser machining, dicing, laser drilling, and surface polishing.

The Role of CNC in Micro Machining

The backbone of micro machining is the Computer Numerical Control (CNC) system. This technology guides the micro machining process by translating digital design files into instructions for the machine tools. The CNC system ensures the accuracy and repeatability of the micro machining process, allowing manufacturers to create intricate parts with dimensions in the micrometer range.

CNC micro machining is a high-precision process that uses advanced technologies such as micro milling and micro turning to manufacture small components. These components are often essential for specific applications in industries like medical, aerospace, and electronics. Furthermore, the use of advanced CAD and CAM software ensures that the final product meets the exact design specifications, contributing to the overall precision and efficiency of micro machining.

Methods of Micro Machining: Micromilling, Laser Machining, Dicing, Laser Drilling, and Surface Polishing

Micro machining involves a variety of techniques, each suited to different materials and applications. Let’s delve into some of these methods:

-

Micromilling: This process involves the use of tiny cutting tools to create intricate features on a workpiece. Micromilling is a versatile technique that can be used on a variety of materials, including metals, alloys, and polymers.

-

Laser Machining: Here, a high-powered laser beam is used to remove material from the workpiece. This technique is often used for drilling, cutting, and engraving operations.

-

Dicing: This method involves cutting a workpiece into small dice-like blocks. It’s commonly employed in the semiconductor industry to separate individual chips from a silicon wafer.

-

Laser Drilling: This is a non-contact process where a laser is used to create holes in a material. It offers high precision and is often used in the production of electronic and medical components.

-

Surface Polishing: This technique smooths the surface of a workpiece to achieve a high degree of finish. It’s often used in optical and medical applications where surface quality is paramount.

Each of these micro machining methods contributes to the creation of tiny, precise components that are integral to a wide range of industries. The versatility and precision of these techniques make micro machining an invaluable tool in today’s manufacturing landscape.

The Precision and Efficiency of Micro Machining Services

As we transition from the broader scope of micro machining methods to the precision they deliver, it’s important to note that the power of micro machining services rests in their incredible accuracy and efficiency.

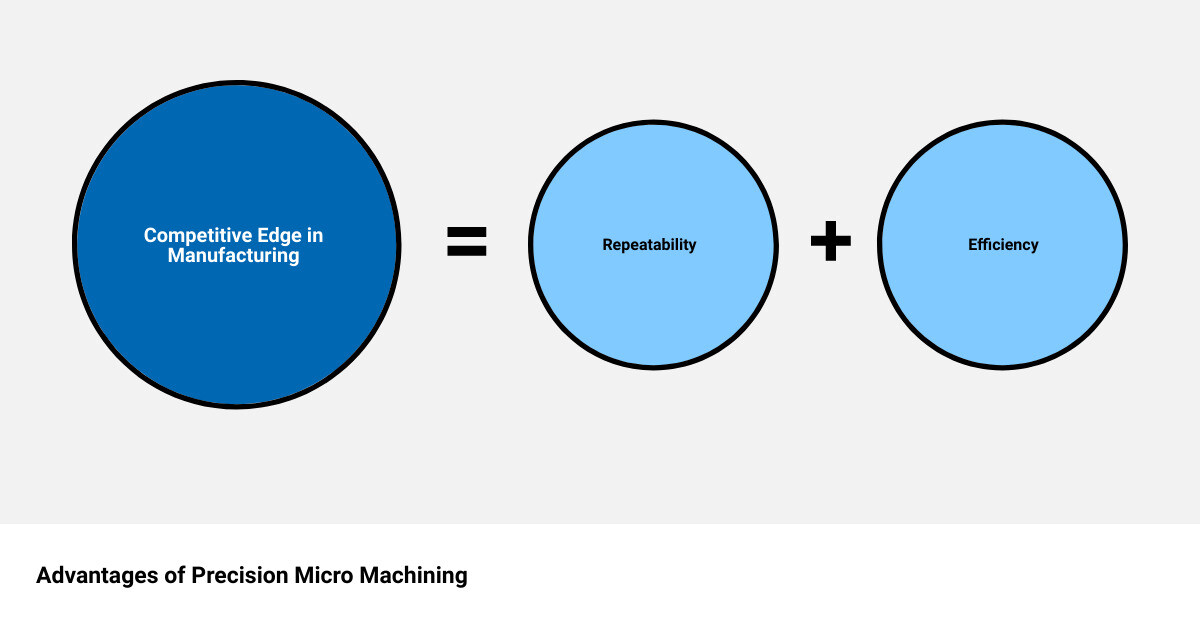

The Advantages of Precision Micro Machining: Repeatability, Efficiency, Versatility, Accuracy, and Competitiveness

Precision micro machining services stand head and shoulders above traditional manufacturing methods thanks to five key advantages: repeatability, efficiency, versatility, accuracy, and competitiveness.

Firstly, the use of specialized micro machines and tools allows for the production of tiny, intricate components with tight tolerances in a repeatable manner. This repeatability ensures consistent quality across large production runs, which is crucial in industries where precision is paramount.

Secondly, micro machining services offer unmatched efficiency. With the ability to machine smaller parts in a single operation, processes such as milling and turning can be completed on the same machine. This not only speeds up production but also increases the overall efficiency of part machining.

Thirdly, the versatility of micro machining is truly impressive. It allows for prototypes and parts requiring micro features to be machined in both plastics and metals, making it suitable for a multitude of applications.

Fourthly, the accuracy of micro machining is beyond compare. High spindle speeds or Swiss-type lathes allow for cleaner cuts and the creation of parts with tighter tolerances and more precise dimensions. This level of accuracy is particularly necessary in specialized applications like the medical and semiconductor industries.

Lastly, implementing micro machining in your precision engineering practice gives you an edge in competitiveness. It enables you to undertake a wider range of bids and receive more diversified and precision parts. Even large parts can be processed with higher accuracy and speed on machines used for micro machining.

The Role of EDM in Micro Machining

In the world of micro machining, Electrical Discharge Machining (EDM) holds a vital role. Sink/Plunge EDM machines, custom-designed for fine plunge patterns, are used to produce the finest details in gears or other micron-scale parts with small and unusual shapes.

The complex geometries in these parts are formed through erosion, caused by sparks between the part being machined and the customized electrodes of the sinker EDM. This process can be used on a variety of materials, including aluminum, brass, stainless steel, titanium, and copper.

Wire EDM cutting is another key player in micro precision machining. The latest models of Wire EDM machines can achieve extremely fine micro machining with .001” diameter cutting wire and 0.1-micron resolution glass scales. This level of precision contributes to the creation of an incredible range of high-quality, intricate components.

In conclusion, the precision and efficiency of micro machining services make them a valuable resource in the world of manufacturing. By offering repeatability, efficiency, versatility, accuracy, and competitiveness, micro machining services are unlocking new levels of precision and potential in various industries.

TMC Technologies: A Leader in Micro Machining Services

In the intricate world of micro machining services, few can compare to the prowess of TMC Technologies. With its impressive track record, TMC Technologies has solidified its standing as a vanguard in this highly specialized field.

TMC Technologies’ Unique Selling Proposition: Top-Tier Quality CNC Components and Additional Machining Services

TMC Technologies is not just a supplier; they are a partner who understands the intricacies of creating precision CNC lathe parts for various industrial machinery. What sets them apart is their unwavering commitment to precision and quality. Every component that comes out of TMC Technologies is a testament to their dedication to creating parts that meet stringent quality standards and precise specifications.

Their expertise extends beyond the mere production of parts. They offer a comprehensive suite of machining services that cater to any CNC lathe parts requirements. This includes CNC milling, CNC turning, CNC grinding, and CNC fabrication services, all handled by a team of highly trained CNC machinists using the most advanced CNC machines.

TMC Technologies also recognizes that every client has unique needs. This understanding drives their commitment to providing tailored solutions and design and fabrication services for custom applications. This focus on customization cements their position as a leader in precision machining parts manufacturing.

TMC Technologies’ Commitment to Quality and Precision in Micro Machining

At the heart of TMC Technologies’ operations is a relentless commitment to quality. Their services undergo rigorous quality control checks throughout the entire production process. This ensures that each component they produce meets the highest standards of precision and accuracy.

This commitment is not only to the quality of components but also to the efficiency of their services. TMC Technologies offers short lead times without compromising on workmanship. Their state-of-the-art automated tools, combined with their highly skilled team, make their services not only efficient but also cost-effective.

In the realm of micro machining services, TMC Technologies stands as a beacon of high precision and quality. Their dedication to excellence makes them a reliable choice for manufacturing companies in need of high precision CNC machining services. For those who value top-tier quality components and a supplier that can assure the accuracy and longevity of your machinery, TMC Technologies is the name you can trust.

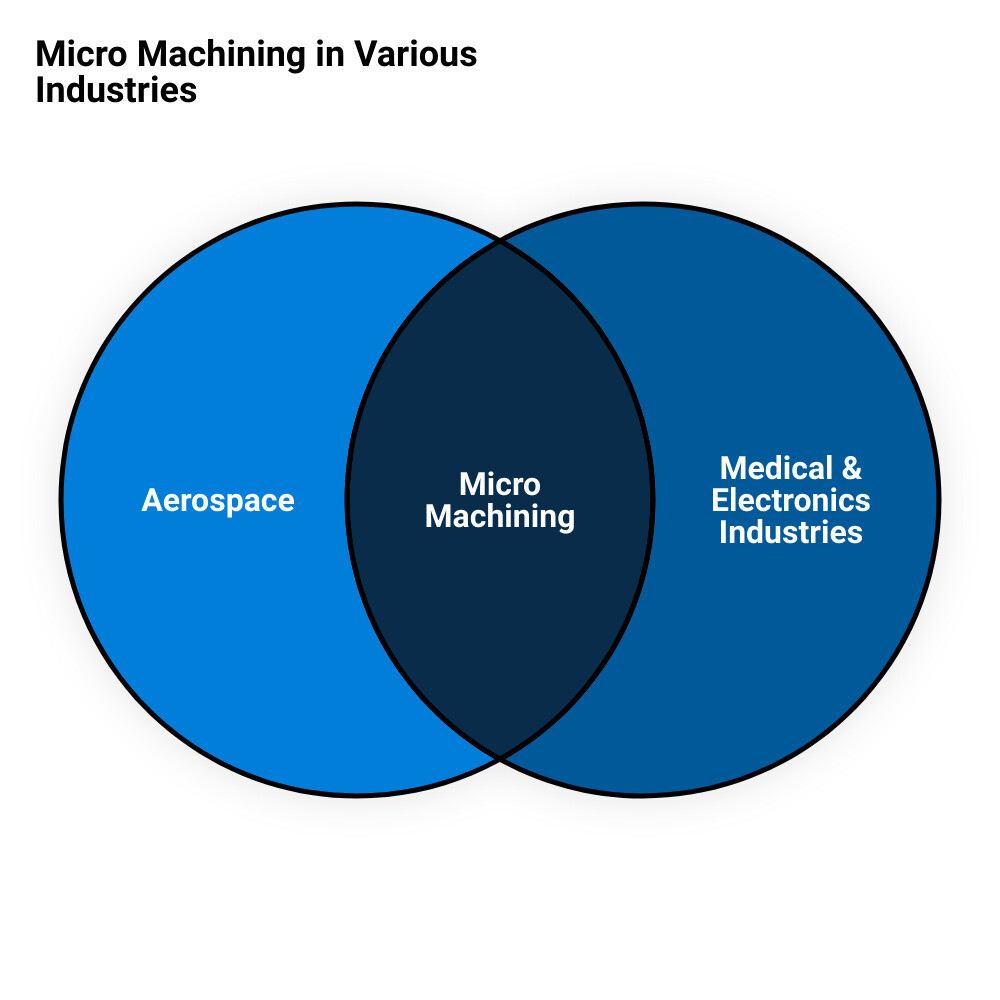

The Impact of Micro Machining Services on Various Industries

From the soaring heights of aerospace to the intricate details of medical devices, micro machining services play an indispensable role across numerous sectors. The precision, efficiency, and versatility offered by these services have revolutionized manufacturing processes, leading to industry advancements and improved end products.

Micro Machining in Aerospace, Medical, Pharmaceutical, and Electronics Industries

In the aerospace sector, micro machining is the unsung hero, crafting complex components with astounding accuracy. Given that the smallest error in this high-stakes environment can have catastrophic results, the precision offered by micro machining is critical. For instance, CNC machines and Swiss machines, which are a part of precision machinery, aid in manufacturing intricate aerospace parts with the highest levels of accuracy.

In the medical and pharmaceutical industries, precision is not just a goal—it’s a necessity. The production of medical devices and surgical tools requires the highest levels of precision and reliability, and this is where micro machining steps in. Swiss machining, known for its superior precision, is used to manufacture complex medical parts such as custom pins and surgical tools.

The electronics industry also benefits from micro machining services. With the trend towards miniaturization in this sector, the demand for parts with complex geometries and tight tolerances has increased. Precision machinery, equipped with advanced CNC technology, helps in shaping these intricate components, thus contributing to the development of smaller, more efficient electronic devices.

Examples of Micromachined Parts: Optical Switch Components, Fiber Optic Components, Miniature Gears, Miniature Shafts, and More

Micro machining services have enabled the production of various micromachined parts that were once deemed impossible or extremely difficult to produce. For instance, in the optical industry, components such as optical switch components and fiber optic components are now being produced with high levels of precision.

In the medical industry, miniature gears and miniature shafts are being efficiently fabricated for various applications. Other examples include sonic nozzles for flow measurement in the aerospace industry and micron surgical scissors used in surgical procedures.

In conclusion, the impact of micro machining services on various industries is profound, enabling the production of complex, high-precision parts with increased efficiency. As technology continues to advance, the role of micro machining in these sectors is set to become even more significant.

Conclusion: The Future of Micro Machining Services

Let’s take a moment to gaze into the future of micro machining services. A future where precision, efficiency, and technological advancements are the driving forces. The future of micro machining services is intertwined with the continued innovation and advancement of technology, especially in the realm of high precision CNC machining.

In the coming years, we can expect to see the integration of new software advancements that will enable more complex and intricate designs to be produced with exact precision. Machine learning and artificial intelligence are not just buzzwords but will be increasingly integrated into micro machining processes, allowing for predictive maintenance, real-time monitoring, and enhanced optimization. This harmonious blend of technology and micro machining practices will undoubtedly result in components with higher accuracy, improved surface finishes, and fewer errors.

On the other hand, automation is set to play a crucial role in the future of micro machining services. The advent of robotic arms and automated tool changers will allow CNC machines to operate with minimal human intervention, increasing productivity while significantly reducing the risk of human error. This integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, will usher in a new era of data-driven decision-making in micro machining, enhancing the precision, efficiency, and reliability of the process.

However, amid all these technological advancements, the role of skilled professionals remains vital. They are the problem solvers and innovators who navigate the complexities of modern micro machining tools, automation, and strict regulatory guidelines. Therefore, the blend of automation and skilled professionals will continue to drive micro machining services to new heights in the future.

In conclusion, the future of micro machining services is bright and filled with possibilities. With companies like TMC Technologies continuing to invest in the latest technology and training, we can look forward to a future where micro machining services are even more precise, efficient, and capable than they are today. Whether it’s for the aerospace, medical, or electronic industries, the application of micro machining services is set to revolutionize the way we design and manufacture components, making it an indispensable tool in our technological arsenal.