Introduction to Aerospace CNC Machining

Emerging at the intersection of technology and precision, Aerospace CNC machining forms the backbone of modern aircraft and spacecraft manufacturing. For businesses like yours, looking for diligent, reliable production of high-grade industrial machinery components, knowing the intricacies of this manufacturing process is essential. At TMC Technologies, we understand the challenges of finding trustworthy suppliers for CNC lathe parts and are aware of the significance of assuring the accuracy and durability of your machinery.

Understanding Aerospace CNC Machining

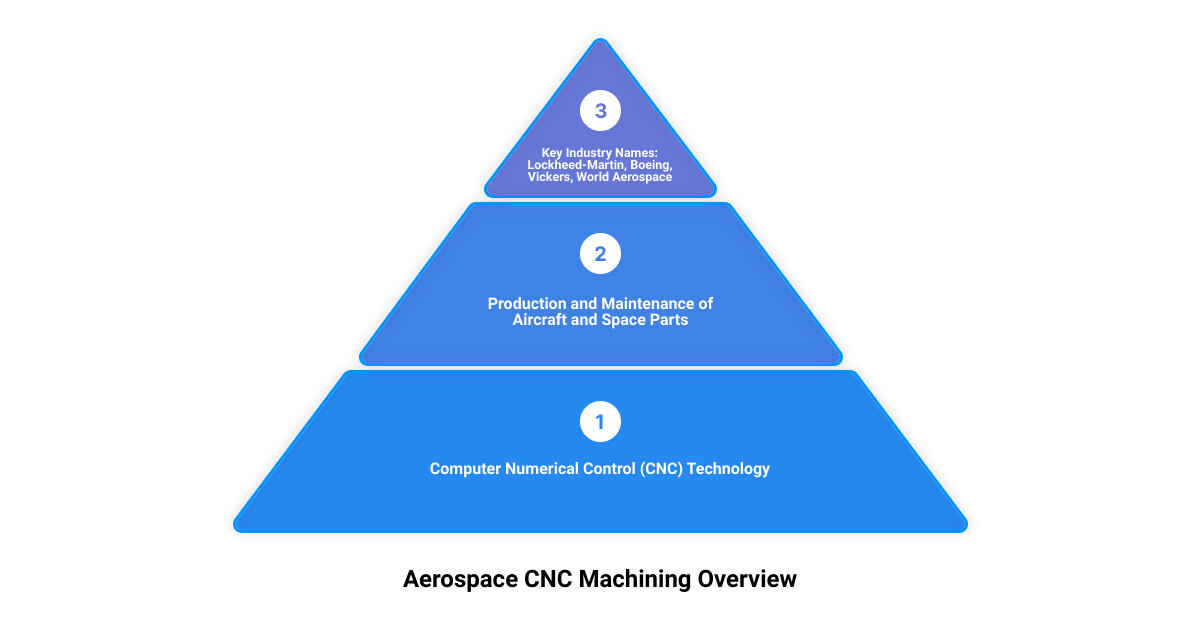

Aerospace CNC Machining is the application of computer numerical control (CNC) technology in the production and maintenance of aircraft and space parts. It involves a computerized production method where cutting tools are maneuvered using pre-developed software and programming code. This automated approach has revolutionized the aerospace industry by simplifying the creation of complex components that were once near impossible to produce.

The Role of CNC in Aircraft Manufacturing

The significance of CNC in aircraft manufacturing is tied to two key concepts: precision and efficiency. With the help of CNC, the production of aerospace components with intricate geometries that are critical to the functionality, safety, and reliability of different types of aircraft, is possible. More importantly, it has greatly improved the efficiency of the manufacturing process by streamlining the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

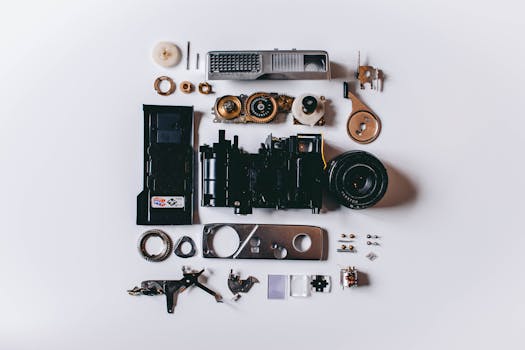

Snapshot of Aerospace CNC Machining:

– Application: Production and maintenance of aircraft and space parts.

– Technology Used: Computer Numerical Control (CNC).

– Resulting Impact: Allows the creation of complex aerospace components and improves efficiency through CAD and CAM software.

– Key Industry Names: Lockheed-Martin, Boeing, Vickers, and World Aerospace.

This infographic concisely covers the basics of Aerospace CNC Machining technology, showcases its application in the industry, and highlights how it results in precise and efficient manufacturing of aerospace components. It further references known names in the industry that rely on this technology for their machinery production.

The Importance of Precision in Aerospace CNC Machining

In the high-stakes game of aerospace manufacturing, precision isn’t just a desirable trait; it’s an absolute necessity. Even the smallest error can lead to catastrophic results, not just in terms of financial costs but also in potential danger to human life. This is why in the world of aerospace manufacturing, precision is a non-negotiable standard.

Why Precision is Crucial in Aerospace Manufacturing

In the aerospace industry, the demand for highly precise components is relentless. Whether we’re talking about commercial airlines, military aircraft, or spacecraft, each of these sectors requires components that are virtually flawless and perfectly measured.

The reason for this is simple: the intense pressures, high altitudes, and extreme temperatures inherent to aerospace applications leave no room for error. The smallest imperfection can result in costly damages or even endanger human life.

Moreover, precision plays a vital role in ensuring optimal functionality under these demanding conditions. From landing gear and motion controls to turbines and actuators, every part produced for aerospace applications must meet exact specifications, eliminating errors and reducing waste.

The Role of CNC Machines in Achieving Precision

When it comes to achieving maximum accuracy in aerospace manufacturing, Computer Numerical Control (CNC) machines are the go-to solution. At TMC Technologies, we leverage advanced technologies, including multi-axis CNC machines, to create high-quality components that meet the exact specifications required in aerospace applications.

These machines, controlled by pre-programmed computer software, perform simultaneous translation and rotational movements, thereby enabling precise machining of intricate parts and complex tool designs. This ability to shape large pieces of material into more precise parts is what makes CNC machines a vital tool in aerospace manufacturing.

Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software packages has significantly streamlined the production process. These tools, combined with the capabilities of CNC machines, allow us to create components that were previously impossible or extremely difficult to produce, thus leading to significant advancements in aerospace design and functionality.

At TMC Technologies, we understand the critical role precision plays in aerospace manufacturing. That’s why we’ve made precision machining central to our production processes. By investing in advanced CNC machinery and maintaining a strict climate-controlled environment, we’re able to manufacture top-quality aerospace components that meet the stringent industry requirements.

In conclusion, precision is not just a goal in aerospace CNC machining – it’s a necessity. And with the help of advanced CNC machinery, we at TMC Technologies are committed to achieving this level of precision, delivering high-quality components that can withstand the demanding conditions of aerospace applications.

The Materials Used in Aerospace CNC Machining

In the fascinating world of aerospace CNC machining, the choice of materials is a vital factor. The materials used in the machining process significantly influence the quality and performance of the final product. In this section, we’ll delve into the common materials used in aerospace CNC machining and the pivotal roles of aluminum and nickel alloys in aerospace manufacturing.

Common Materials Used in Aerospace CNC Machining

At TMC Technologies, we understand that high-quality machining would be futile without the appropriate materials for the job. The materials we frequently use for precision machining include aluminum, brass, stainless steel, and titanium.

Aluminum, known for its lightweight and robust nature, is a favored choice in precision machining. Its excellent machinability and the ability to fabricate complex shapes precisely make it a darling in a range of industries, from aerospace to electronics.

Brass, a beautiful blend of copper and zinc, is another go-to material thanks to its corrosion resistance, low friction, and excellent heat conductivity. It’s a preferred choice for manufacturing gears, valves, and fittings, especially when intricate designs are involved.

Stainless steel, with its high strength, resistance to corrosion, and excellent heat resistance, is popular in sectors like automotive, aerospace, and medical equipment manufacturing. And then, there’s titanium and exotic alloys, known for their high strength-to-weight ratio, corrosion resistance, and exceptional performance under extreme conditions, frequently seen in the aerospace and medical industries.

The Role of Aluminum and Nickel Alloys in Aerospace Manufacturing

In the aerospace industry, aluminum and nickel alloys hold a significant place. Aluminum, the third most abundant element on earth, is a popular material due to its strength, durability, and lightweight properties. It’s easy to shape and machine, meeting stringent industry requirements while lowering manufacturing costs.

Nickel alloys, on the other hand, are integral to aerospace applications. These high-temperature alloys, known for their corrosion resistance, are perfect for creating engine parts, gas turbines, and other crucial components. At TMC Technologies, we understand the importance of using these materials for aerospace applications and have a high amount of nickel aerospace alloys and aluminum in our inventory.

In conclusion, the materials used in aerospace CNC machining, along with advanced manufacturing equipment, form a vital part of the aerospace manufacturing process. Ensuring the best material selection is fundamental in producing components that are accurate, durable, and reliable. In the next section, we will explore TMC Technologies’ role in the aerospace CNC machining industry and how we leverage these materials in our manufacturing processes.

The Role of TMC Technologies in the Aerospace CNC Machining Industry

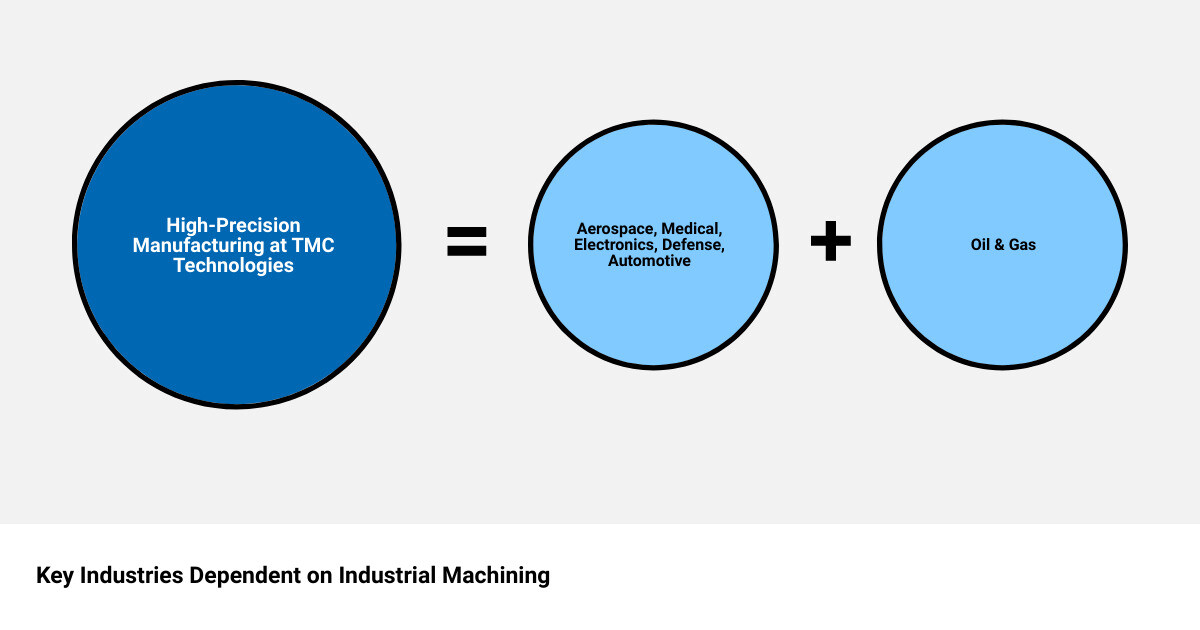

Overview of TMC Technologies

In the world of precision aerospace machining, TMC Technologies emerges as a luminary. With over three decades of experience, we have taken a quantum leap in the realm of precision machining, employing cutting-edge technology to deliver unparalleled precision and consistency in aerospace components manufacturing. Our seasoned engineers and technicians bring an unmatched level of expertise to the table, utilizing the latest machining technologies such as 3D modeling, CNC turning, and machining to guarantee accuracy and superior workmanship.

TMC Technologies’ Unique Selling Proposition

So, what sets TMC Technologies apart from the rest in this competitive aerospace CNC machine shop landscape? Our approach to precision machining services goes beyond high-quality manufacturing. We pride ourselves on offering an extensive range of services that include grinding, heat treating, light fabrication/assembly, and various other secondary operations.

Our state-of-the-art automated tools and technology enable us to manufacture a variety of materials efficiently and cost-effectively, including aluminum alloys, brass, titanium, stainless steel, and plastics. These materials, as we’ve discussed, are critical for aerospace applications due to their strength, durability, and light weight.

Moreover, we at TMC Technologies understand the urgency that often accompanies the need for precision parts. As such, we strive to deliver short lead times without compromising the high-quality workmanship that we are known for.

But our commitment doesn’t stop at delivering top-notch precision machining services. We also place a high value on customer satisfaction. Our unwavering attention to detail and commitment to quality ensures that each client can rely on their machining needs being met to the highest standards.

In summary, our unique selling proposition lies in our combination of extensive industry experience, cutting-edge technology, rigorous quality control, and a commitment to customer satisfaction. These factors all contribute to making TMC Technologies a trusted partner in the realm of precision aerospace machining. In the next section, we will delve into the future of aerospace CNC machining and the role that TMC Technologies plays in shaping it.

The Future of Aerospace CNC Machining

In a world that is increasingly dependent on technology, the future of aerospace CNC machining is set to be exciting. Advancements in technology have always been at the heart of aerospace manufacturing, and now more than ever, we are seeing the impact of technological progress on this industry.

The Impact of Technological Advancements on Aerospace CNC Machining

The advent of multi-axis CNC machines, computer-aided design (CAD), and computer-aided manufacturing (CAM) software packages have revolutionized the aerospace industry. These technologies have enabled manufacturers to produce intricate components with unprecedented precision, fulfilling the rigorous international quality standards that this industry demands.

Moreover, the incorporation of high-speed spindles and conversational control programming in Vertical Machining Centers (VMCs) has made these machines a popular choice among small companies. The ability to manufacture complex parts with a single-setup machining process has not only simplified the production process but also significantly reduced labor costs, increased part quality, and cut down work time.

As CNC technology continues to evolve, its role in the aerospace industry is only set to increase. Innovations in automation, data analysis, and precision engineering are continually being integrated into CNC machining centers, shaping the future of aerospace manufacturing.

How TMC Technologies is Adapting to Future Trends in Aerospace CNC Machining

At TMC Technologies, we are not just observers of this technological revolution; we are active participants. As a leading CNC machine shop with decades of experience in aerospace applications, we are constantly adapting our methodologies and equipment to keep pace with the latest trends in the industry.

Our team of highly trained professionals uses cutting-edge CNC equipment to produce high-quality, precise components that meet the stringent standards of the aerospace industry. We offer comprehensive services such as prototyping, reverse engineering, production runs, welding, and fabrication services.

In addition to our ongoing commitment to technological innovation, we also prioritize customer service. We understand that our customers need their CNC machined parts quickly and accurately, and we are committed to providing exceptional service to meet these needs.

The future of aerospace CNC machining is bright, and at TMC Technologies, we are excited to be part of this revolution. We look forward to continuing to deliver exceptional service and state-of-the-art CNC machined parts to our customers in the aerospace industry.

As we continue to navigate the exciting future of aerospace CNC machining, TMC Technologies remains dedicated to advancing our capabilities and services in line with technological progress. We’re not just watching the revolution unfold; we’re actively participating in it, ensuring our customers always have access to the most advanced, efficient, and precise machining services available.

The future of aerospace CNC machining is here, and we’re proud to be at the forefront of this exciting revolution. Join us on this journey as we continue to push the boundaries of what’s possible in the world of precision aerospace machining.

Conclusion: The Aerospace CNC Machine Shop Revolution

The aerospace industry is a realm where precision, accuracy, and quality are non-negotiable. Here, even the tiniest error can have catastrophic consequences, which is why aerospace manufacturers rely extensively on the capabilities of CNC machine shops.

The Role of CNC Machine Shops in the Aerospace Industry

In the high-stakes environment of aerospace manufacturing, CNC machine shops like TMC Technologies play a pivotal role. From the production of complex components for aircraft and spacecraft to the maintenance of these high-tech machines, the expertise we offer is indispensable. Our state-of-the-art CNC machining centers, staffed by experienced and highly trained machinists, have the capability to produce parts with innovative designs that meet exact specifications.

The use of advanced technologies, like multi-axis CNC machines and computer-aided design (CAD) and computer-aided manufacturing (CAM) software packages, streamlines the production process and ensures a more efficient workflow. This not only helps us meet strict international quality standards, but also ensures that the components we produce meet the functional and regulatory requirements of the aerospace industry.

The Potential of Aerospace CNC Machine Shops in the Future

As we look ahead, the future of aerospace CNC machining is bright. The ongoing advancements in technology are continually expanding the capabilities of CNC machining, opening up new possibilities for precision, efficiency, and innovation in aerospace manufacturing.

At TMC Technologies, we are committed to staying at the forefront of these exciting developments. We are continually evolving, integrating the latest innovations in automation, data analysis, and precision engineering into our operations. This allows us to deliver the highest quality components, while also improving efficiency and reducing costs.

In the future, the potential of aerospace CNC machine shops like ours is vast. As the demand for more advanced, efficient, and reliable aircraft and spacecraft continues to grow, so too will the need for the precision and expertise that we offer.

We are eager to meet these challenges head-on, pushing the boundaries of what’s possible in aerospace CNC machining and contributing to the advancement of this critical industry. The aerospace CNC machine shop revolution is well underway, and we’re proud to be leading the charge.

In conclusion, the impact of CNC machining centers on various industries, particularly the aerospace industry, is undeniable. They have revolutionized the manufacturing process, delivering precision and efficiency while meeting the industry-specific demands. The future is bright, and we are excited for what’s to come.

As we work towards the future, we will continue to leverage our expertise and innovative technologies to provide the most advanced, efficient, and precise machining services available. The future of aerospace CNC machining is here, and we’re proud to be at the forefront of this exciting revolution. Join us on this journey as we continue to push the boundaries of what’s possible in the world of precision aerospace machining.