At the core of every advanced manufacturing process lies a silent powerhouse—industrial machining. This process serves as the backbone of various industries, shaping and removing material from workpieces to create intricate parts with impressive accuracy. Here at TMC Technologies, we are no stranger to the critical role of industrial machining in precision engineering.

Definition of Machining

Industrial machining is a process that involves the use of machine tools to cut, shape, or remove material from a workpiece. The primary goal is to manufacture parts that meet exact specifications. This process is often guided by advanced machinery and precise techniques, which significantly reduce waste and the possibility of human error, enhancing overall quality control in the manufacturing process.

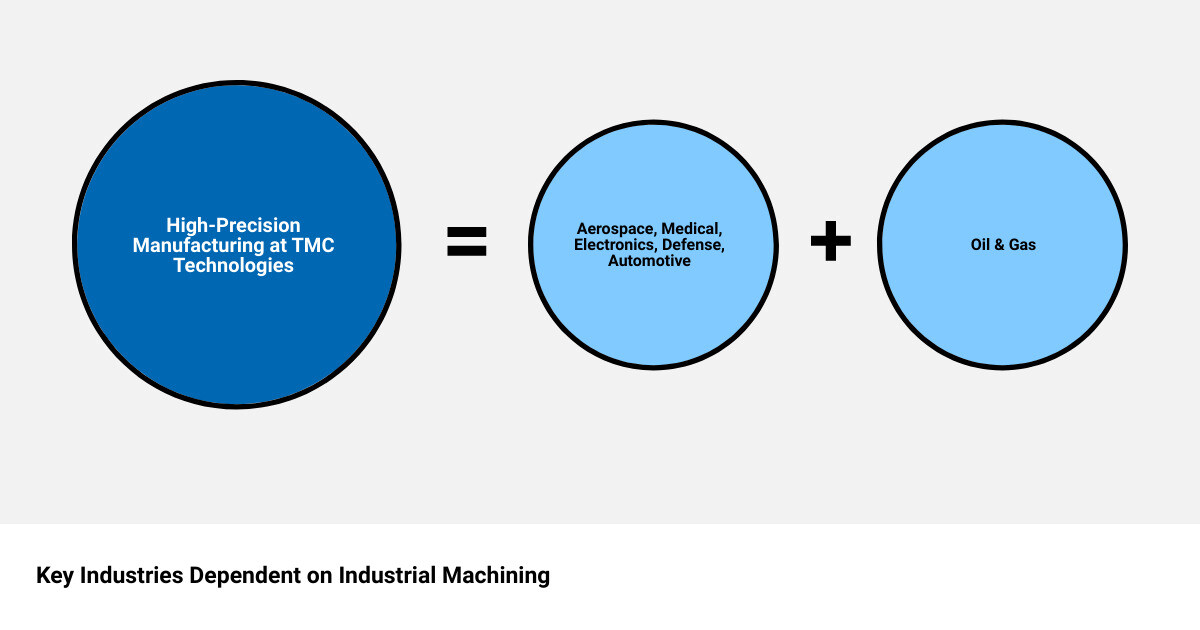

Importance of Industrial Machining in Various Industries

Industrial machining is not just a vital component of the manufacturing sector—it’s an indispensable tool across a multitude of industries. Aerospace, medical, electronics, defense, automotive, and oil & gas industries all heavily rely on precision machining to create accurate components that meet their high-level needs.

In the demanding medical industry, precision machines such as Swiss machines are used to manufacture complex parts like custom pins and surgical tools. The automotive industry uses precision machining to produce high-quality, reliable, and safe components, contributing to the overall performance and longevity of vehicles. In the defense sector, precision is paramount, making precision machinery and CNC machines critical in manufacturing complex parts that meet stringent safety and performance standards. The electronics industry, with its trend of miniaturization, also heavily relies on precision machinery to manufacture intricate components with complex geometries and tight tolerances.

Key Industries Dependent on Industrial Machining

– Aerospace

– Medical

– Electronics

– Defense

– Automotive

– Oil & Gas

Stay tuned as we delve deeper into the fascinating world of industrial machining, exploring its various processes, and shedding light on how we, at TMC Technologies, leverage this technology for high-precision manufacturing.

Understanding the Process of Industrial Machining

Unfolding the mysteries of industrial machining is like opening a well-crafted, complex timepiece. Each stage, from design to assembly, is a crucial cog in the overall process, working in harmony to produce a precision-machined component that meets stringent specifications.

Designing Stage of Industrial Machines

The journey of a precision machined component begins not on the production floor, but in the realms of digital design. As we at TMC Technologies can attest, the first step towards bringing a component to life involves sophisticated CAD modeling. Using advanced engineering software like Master Cam, Gibbs Cam, and Solid Works, every detail is meticulously planned and executed to perfection. These digital blueprints guide the entire manufacturing process, ensuring the highest quality and precision in every component produced.

Prototyping Stage of Industrial Machines

Fast on the heels of design comes the prototyping phase, a crucial step in materializing a component from its digital blueprint. Rapid prototyping allows for the creation of a physical model of the component, providing an opportunity to assess the design in a real-world context. Any potential issues can be identified and rectified before moving on to the manufacturing stage.

Manufacturing Stage of Industrial Machines

Once the design and prototype have been finalized, it’s time to get down to the business of manufacturing. At the heart of this process lies the cutting-edge multi-axis CNC machining technology. From milling to turning, cross-drilling to engraving, this advanced machinery performs a variety of processes all in one go. The beauty of this technology lies in its ability to eliminate secondary processes and reduce the potential for human error, thereby driving efficiency while maintaining the highest level of precision.

Assembly Stage of Industrial Machines

The assembly stage is where all the manufactured parts come together to form the final product. But the journey doesn’t stop there. Secondary processes like plating, heat treatments, and grinding are essential to achieve the required finish and ensure the part’s durability and longevity. These processes, combined with advanced machining techniques, allow companies like TMC Technologies to consistently deliver components that meet your exact specifications.

In conclusion, the process of industrial machining is a carefully orchestrated symphony of technology, expertise, and precision. Each stage plays a crucial role, working in harmony to produce a high-quality, precision-machined component. Whether you’re in the aerospace, medical, electronics, or defense industry, understanding this process is key to ensuring the accuracy and longevity of your machinery.

The Role of CNC Machining in Industrial Manufacturing

The world of industrial manufacturing is continually evolving, and Computer Numerical Control (CNC) machining stands as one of its key pillars, shaping the sector with its high precision and efficiency. In fact, it is the linchpin of the modern industrial machining process.

Definition of CNC Machining

CNC machining is an advanced manufacturing process where pre-programmed computer software dictates the movements of factory tools and machinery. The computer-aided design (CAD) and computer-aided manufacturing (CAM) systems feed the CNC machines precise instructions on how to create the desired component. The result? A seamless production of parts that meet exact specifications with exceptional precision and repeatability.

CNC machines are not just limited to milling; they can carry out a range of tasks such as turning, cross-drilling, and engraving. This ability to multi-task makes them an invaluable asset in the industrial manufacturing sector.

The Use of CNC Machining in Industrial Manufacturing

The role of CNC machining in industrial manufacturing is pivotal. It revolutionizes the production process by automating the shaping of raw materials into complex parts with exact dimensions, thus ensuring high precision and quality control.

At TMC Technologies, we utilize state-of-the-art CNC machines, such as three-axis, four-axis, and five-axis CNC milling machines, to create complex shapes and perform milling from any angle. This approach not only ensures exceptional precision but also unparalleled repeatability, resulting in components manufactured to the most exacting standards.

As a leading provider of high-quality precision machining services, we understand the value of accuracy, efficiency, and longevity in various manufacturing processes. CNC machining allows us to minimize waste by reducing scrap from incorrect dimensions or damaged surfaces, ensuring an efficient use of resources. More than that, CNC machining significantly reduces the possibility of human error, enhancing the overall quality control in the manufacturing process.

Whether it’s engine parts, custom fasteners, or intricate parts for navigation systems, these components are produced with the highest level of accuracy, ensuring they fit perfectly and function optimally. This level of quality is pivotal to the overall performance and longevity of final products across various industries, from automotive to aerospace.

To sum up, CNC machining is not just a process; it’s a game-changer in the industrial manufacturing world. By enabling the production of precise, high-quality components, it is shaping the future of industries and paving the way for advancements in technology.

TMC Technologies: A Case Study in High-Quality Industrial Machining

Industrial machining is a vast field, and the need for precise, high-quality components is paramount for industries to function effectively. One company that stands out in this sphere is TMC Technologies.

Overview of TMC Technologies

With over three decades of experience, TMC Technologies has established itself as a leader in the world of industrial machining. Our team is composed of highly skilled engineers and technicians who are adept at utilizing the latest machining technologies to guarantee accuracy and superior workmanship.

The services we offer span a wide range of industries, from food processing to aerospace and military applications. TMC Technologies has a well-established track record of excellence. Our CNC milling capabilities include both 3 and 4 axis equipment in vertical and horizontal configurations, which allows us high flexibility in meeting customer needs based on design and volume.

TMC Technologies’ Unique Selling Proposition

So, what sets us apart in the competitive field of industrial machining? At TMC Technologies, our unique selling proposition lies in our unwavering commitment to precision and quality.

Our services undergo rigorous quality control checks throughout the entire production process, ensuring that each component we produce meets the highest standards of precision and accuracy. Moreover, we understand the urgency that often accompanies the need for precision parts. As such, we strive to deliver short lead times without compromising the high-quality workmanship that we are known for.

We offer more than just high-quality manufacturing. Our range of services includes design and fabrication services for custom applications, acknowledging that every client has unique needs. Our focus on customization establishes TMC Technologies’ commitment to providing tailored solutions, marking our position as a leader in precision machining parts manufacturing.

In conclusion, TMC Technologies is more than a manufacturer; we are a reliable partner that understands your needs, values quality, and delivers precision. This dedication to excellence solidifies our role as a leading name in the world of industrial machining. If you value top-tier quality components and a supplier that can assure the accuracy and longevity of your machinery, TMC Technologies is a name you can trust.

Quality Control in Industrial Machining

Ensuring quality in industrial machining is no mere detail—it’s the backbone that underpins the entire process. From aerospace to medical industries, the stakes are simply too high to compromise on quality. Precision is paramount, and it’s this precision that sets apart the good from the great in the world of industrial machining. Let’s delve into why quality control is so crucial and how we at TMC Technologies are raising the bar.

Importance of Quality Control in Industrial Machining

In industrial machining, even a micron’s difference can have significant implications. This is why quality control is so essential. It’s not just about meeting standards—it’s about exceeding them, pushing boundaries, and striving for perfection.

Quality control is not just a means to ensure the functionality and longevity of machinery. It’s also a crucial factor in safety, particularly in sectors like the aerospace industry where the stakes are incredibly high. Robust quality control measures result in reliable, high-performance components that meet the stringent requirements of various industries.

Quality Control Measures at TMC Technologies

At TMC Technologies, we don’t just understand the importance of quality control—we live it. We believe that precision shouldn’t be an aspiration, but a standard. As such, we have developed a meticulous approach to quality assurance that ensures every component we produce is perfect down to the last micron.

Our commitment to quality control begins with our use of state-of-the-art CNC equipment. This equipment provides accurate and repeatable results, forming the basis of our quality assurance process. But as we all know, the machinery is only as good as the people operating it. That’s why we have a team of seasoned CNC technicians who are continuously trained on the latest technology and techniques. This ensures that we can maximize the capabilities of our equipment and deliver parts that exceed expectations.

But our commitment to quality doesn’t stop there. We also employ stringent inspection tools, like CAD and CAM programs, to create digital blueprints that our precision machining tools can read. This allows for a greater level of accuracy compared to human-operated machines and results in the intricate removal of material.

Our steadfast attention to detail is another crucial component of our quality control measures. This ensures that every part we create aligns with the exact specifications provided by the client.

At TMC Technologies, quality control is more than a process—it’s a culture of excellence that permeates every aspect of our work. By choosing us as your industrial machining partner, you’re choosing a commitment to quality, precision, and unparalleled performance.

The Future of Industrial Machining

Technological advancements and the rise of automation are stirring a revolution in the world of industrial machining – a revolution that we, at TMC Technologies, are proud to be a part of.

Technological Advancements in Industrial Machining

With each passing day, the landscapes of industrial machining are being reshaped, with the advent of new technologies and sophisticated software. From the rise of automation to the integration of machine learning and artificial intelligence, every aspect of industrial machining is evolving at an unprecedented pace.

The world of high precision CNC machining, in particular, is witnessing a continuous evolution. New software advancements are facilitating the production of more complex and intricate designs with exact precision. This is in addition to the rise of 5-axis CNC machines, which are revolutionizing the industry by enabling the manufacture of complex parts with fewer setups and shorter lead times.

Moreover, the advent of Industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, is bringing about a new level of connectivity and data-driven decision-making in CNC machining. This is leading to improved quality control, predictive maintenance, and process optimization, enhancing the precision, efficiency, and reliability of CNC machining processes.

The Impact of these Advancements on Industries

The impact of these advancements on various industries is profound. For instance, the aerospace industry, which demands utmost precision and quality, has benefitted immensely from the precision offered by advanced CNC machining. As we noted in our exploration of CNC Machining Centers, the combination of CAD and CAM software has streamlined the manufacturing process, ensuring that all components meet strict international quality standards.

Moreover, the economic impact of these advancements is equally significant. With lower operating costs, faster turnaround times, and higher quality output, businesses can become more competitive, agile, and responsive to market demands. As a result, even small companies can now access the same level of precision and quality as their larger counterparts, all at a fraction of the cost.

In conclusion, it’s evident that the future of industrial machining is not a distant dream, it’s happening right now. As we forge ahead at TMC Technologies into this exciting new era, one thing is clear – industrial machining, underpinned by the continual advancements in technology, is set to transform the manufacturing landscape, shaping the future of various industries.

As the architects of tomorrow’s industry, we are committed to staying at the forefront of these advancements, leveraging our expertise to deliver high-quality, precision-engineered parts to our clients. The future is bright for industrial machining, and we can’t wait to see what the next chapter holds.

Conclusion: The Integral Role of Industrial Machining in Modern Industries

From the production of vital medical equipment to the manufacture of critical aerospace components, the importance of industrial machining cannot be overstated. Its influence extends far beyond the factory floor, shaping our world in ways that often go unnoticed.

The precision, efficiency, and reliability offered by advanced machinery like CNC machines and Swiss machines have revolutionized industries, setting new standards for quality and performance. At TMC Technologies, we have seen firsthand the transformative power of these machines. Their ability to craft complex geometries with staggering accuracy makes them indispensable in industries where precision is a non-negotiable requirement, such as aerospace, medical, and electronics.

The role of industrial machining is not just confined to the precise shaping of materials. It also contributes significantly to the overall reliability and performance of products. For instance, in the electronics industry, precision machinery achieves a high degree of repeatability, ensuring every component produced matches the original design specifications. This contributes to the longevity and performance of electronic devices, enhancing user experience and satisfaction.

Industrial machining also plays a vital role in the medical and dental sectors. The stakes here are incredibly high, with patient health and safety at the forefront. Swiss machining, renowned for its superior precision, is commonly used to manufacture complex medical parts like custom pins and surgical tools. This ability to work with a variety of materials, including stainless steel, aluminum, and titanium, allows for the creation of durable, high-quality medical devices that can withstand rigorous medical use.

As we look to the future, the role of industrial machining is set to become even more critical. Technological advancements, such as AI and machine learning, are poised to take industrial machining to new heights. At TMC Technologies, we are excited to be part of this future, leveraging our expertise and commitment to quality to deliver high-precision components that meet the evolving needs of our customers.

In conclusion, industrial machining is not just a component of the manufacturing process; it is the backbone on which modern industries stand and thrive. It is the silent workhorse powering the infrastructure of our modern world, crafting the components that keep our world running smoothly. As we forge ahead, we at TMC Technologies remain committed to embodying these values, delivering high-quality, precision-engineered parts that power the future of various industries.