Welcome to the fascinating world of CNC fabrication, a technology that has revolutionized industries by turning complex concepts into tangible reality. The bedrock of industries like automotive, aerospace, and medical equipment manufacturing, Computer Numerical Control (CNC) fabrication has taken precision engineering to unprecedented heights. At TMC Technologies, we are at the forefront of such innovation, continually pushing the envelope in precision, quality, and customization to meet and exceed the unique requirements of our clients.

CNC fabrication is a computerized process that employs software and numerical codes to control production equipment. The machinery carves out required designs from a blank or solid block of material such as wood, metal, or plastic to precise specifications, giving birth to detailed parts essential to various industries. It’s like sculpting, but with the highly controlled movements of a machine rather than the artist’s chisel. This subtractive manufacturing process uses a range of highly precise techniques such as cutting, carving, bending, and laser cutting.

The sphere of influence for CNC fabrication extends to a wide range of industries. From the creation of minute medical devices to industrial parts for freight trains and spacecraft to intricate art pieces, this versatile technology has been playing a pivotal role in shaping our cultural, industrial, and medical landscapes.

Here’s a quick overview of the way CNC fabrication impacts different sectors:

- Aerospace Industry: Highly efficient, all thanks to the precise design and durability of CNC machined components.

- Automotive Manufacturing: Relies heavily on precision machined parts for optimal car performance.

- Medical Equipment Manufacturing: Involves specialized components designed with high precision to ensure patient safety.

- Art and Sculpture: Uses CNC for creating immaculately detailed sculptures and artifacts.

- Small scale manufacturing: Employs CNC machinery for cost-effective, precise, and efficient production.

In summary, CNC fabrication is responsible for the seamless functioning of various industries. As an expert in this field, TMC Technologies harnesses the capabilities of CNC fabrication to meet the pressing needs of companies like yours, who value top-tier quality components and expect additional machining services for custom requirements. Stay with us as we unravel more secrets of this revolutionary technology.

The Process of CNC Fabrication

Unveiling the mechanics of CNC fabrication is akin to revealing the ingredients of a master chef’s recipe. This process, while complex, is the secret sauce behind the high-precision components we produce at TMC Technologies. Let’s delve into the intricacies of the CNC machining process, its subtractive manufacturing approach, and the plethora of techniques it employs.

Understanding the Computerized Process of CNC Machining

The heart of CNC fabrication lies in its computerized operation. Known as Computer Numerical Control (CNC) machining, this process employs software and code to dictate the movements of production equipment. In simpler terms, it’s like a virtual puppeteer pulling the strings of a machine to carve, cut, or shape a solid block of material into an intricate part.

The beauty of this process lies in its precision. The CNC machine follows a digital blueprint, developed through CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs. This blueprint serves as the roadmap for the CNC machine, guiding it to carve out the desired component with incredible accuracy. This computer-controlled process doesn’t just ensure precision, but also repeatability – an invaluable asset when manufacturing to the most exacting standards.

The Subtractive Manufacturing Process of CNC Machining

Unlike 3D printing, which adds layers of material to form an object, CNC machining is a subtractive process. It begins with a solid block of material, known as a blank, and systematically removes material until the final product is created. This process can work with a variety of materials, including wood, metal, plastic, and foam.

One of the key advantages of the subtractive process is its ability to retain the structural integrity of the material even as it carves out intricate details. It ensures that the final product doesn’t just look good, but also performs exceptionally in its intended application.

Techniques Used in CNC Machining: Turning, Milling, Drilling, Grinding

CNC machining isn’t a one-trick pony. It boasts a wealth of techniques to cut, shape, and carve materials, offering a much higher level of accuracy than traditional hand-carving.

For instance, in CNC Turning, the cutting tool rotates, removing material in a pattern programmed by the equipment. CNC Milling, on the other hand, employs multi-point rotary cutters to remove material, ensuring full structural integrity of the material. CNC Drilling uses a two-edged rotating device to drill exact round holes, while CNC Grinding uses a rotating wheel to remove material. Each of these techniques contributes to the superior precision and quality of the final product.

At TMC Technologies, we harness these techniques and more to deliver high-quality CNC lathe parts to our clients. Whether it’s creating custom fasteners or intricate parts for navigation systems, our CNC fabrication process guarantees precision, efficiency, and longevity. Stay tuned as we delve into the many advantages of CNC fabrication in the next section.

The Advantages of CNC Fabrication

In the world of industrial manufacturing, CNC fabrication is more than just a trend—it’s a game-changer. Harnessing the power of computerized precision, CNC machining has revolutionized the sector, delivering unparalleled benefits that extend far beyond just accuracy. At TMC Technologies, we leverage these advantages to provide our clients with top-tier quality components and additional machining services for custom applications. Let’s delve into the myriad benefits that this cutting-edge technology brings to the table.

Speed and Efficiency of CNC Machining

One of the most compelling advantages of CNC fabrication is its inherent speed and efficiency. Thanks to advanced techniques such as multi-axis CNC machining and Swiss machining, production times are significantly reduced. These techniques save substantial setup time and reduce the potential for human error that may occur during part repositioning.

Swiss machining, in particular, allows machines to run unattended for extended periods, facilitating higher production volumes with less labor. This increased efficiency translates into faster turnaround times, enabling us to meet tight deadlines and handle large volumes of parts without compromising accuracy or quality.

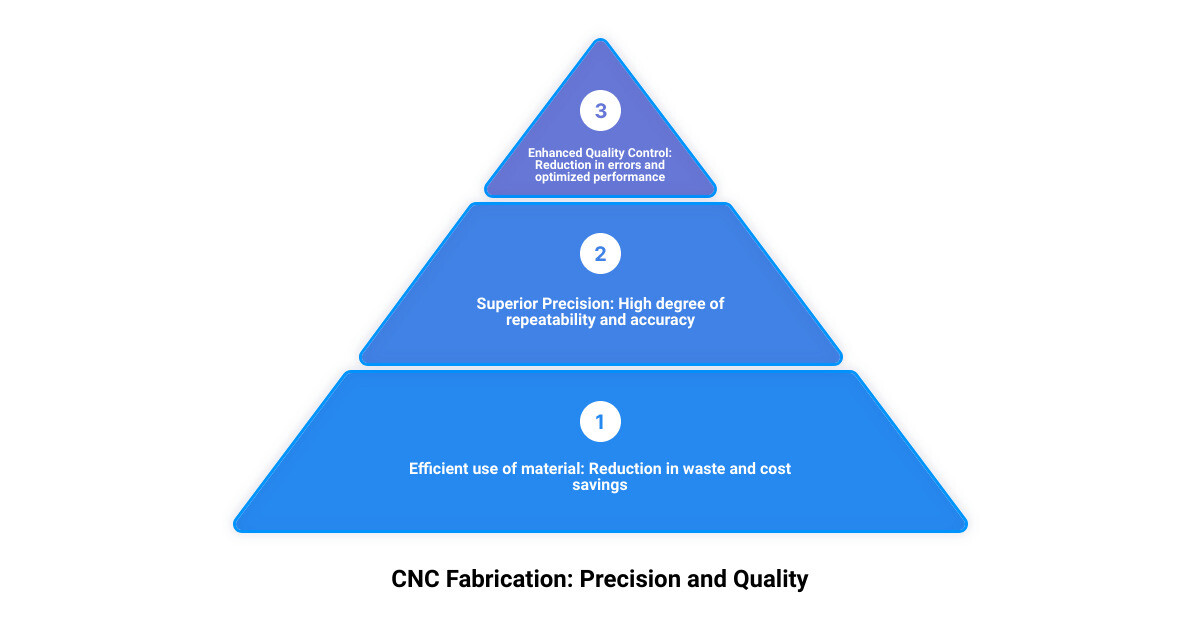

Cost-Effectiveness of CNC Fabrication

CNC fabrication is also a cost-effective option for manufacturing components. By eliminating the need for manual labor, significant savings can be achieved. Furthermore, the precise control afforded by CNC machining leads to more efficient use of material, reducing waste from excess material and incorrect dimensions.

This reduction in material waste not only results in cost savings but also contributes to more sustainable manufacturing practices—an aspect that’s becoming increasingly important in today’s environmentally-conscious world.

Precision and Quality of CNC Fabricated Parts

Perhaps the most touted benefit of CNC fabrication is the unparalleled precision and quality it delivers. By leveraging advanced computerized machine tools, CNC machining enables the creation of complex geometric cuts with a high degree of repeatability and accuracy. This means that parts are machined to the same tight tolerances repeatedly, regardless of the production volume.

With the use of CAD and CAM systems, we ensure that the final product meets the exact design specifications. This precision significantly reduces the possibility of errors, enhancing overall quality control. Plus, the superior precision of CNC fabrication allows for the creation of intricate details on ornamental pieces, such as engravings and etchings, with unmatched accuracy.

At TMC Technologies, we capitalize on these benefits of CNC fabrication to deliver meticulously crafted parts designed to optimize the performance of various machinery. Our commitment to precision, efficiency, and cost-effectiveness ensures that we continue to serve as a reliable partner for industries in need of top-tier quality components and additional machining services for their custom applications.

TMC Technologies: A Leader in CNC Fabrication

At TMC Technologies, the future of fabrication is not just about making parts – it’s about crafting solutions that drive innovation and efficiency across a multitude of industries.

Overview of TMC Technologies and Their Specialization in CNC Lathe Parts

We’re not just a company, but a team of dedicated professionals who breathe life into various materials, transforming them into precise, high-quality CNC lathe parts. From prototypes to full-scale production runs, we ensure that every part we produce stands as a testament to our unwavering commitment to detail and accuracy.

Our advanced CNC machines and highly skilled machinists ensure that every CNC lathe part we produce is tailored to meet our customers’ exact requirements. We utilize a range of CNC techniques like CNC milling, turning, sawing, drilling, grinding, lapping, threading, and tapping to deliver parts that not only meet, but exceed industry standards.

The Unique Selling Proposition of TMC Technologies: Quality and Customization

What differentiates us in this competitive landscape is our unwavering commitment to precision and quality. Our unique selling proposition lies in our combination of extensive industry experience, cutting-edge technology, rigorous quality control, and a commitment to customer satisfaction.

We understand that every client has unique needs and, therefore, we focus on customization. This establishes our commitment to providing tailored solutions, marking our position as a leader in precision machining parts manufacturing. To us, delivering precision parts of the highest quality is not just a promise – it’s a commitment we fulfill every day.

Additional Services Offered by TMC Technologies: Tool Design and Fabrication

At TMC Technologies, we offer more than just high-quality manufacturing. We also provide additional services such as tool design and fabrication services for custom applications. We understand that every project is unique, and we strive to offer solutions that are as individual as our clients.

Our range of services also encompasses grinding, various secondary operations, heat treating, and light fabrication/assembly. This allows us to position ourselves as a one-stop-shop for all your CNC needs, offering convenience and efficiency for our clients.

In the end, we believe in the power of precision, the importance of quality, and the value of customer satisfaction. At TMC Technologies, we are more than just a manufacturer – we are a reliable partner that understands your needs, values quality, and delivers precision.

As we continue to redefine the future of CNC fabrication, we invite you to join us in this exciting journey towards innovation, efficiency, and unmatched quality.

Hiring a CNC Fabrication Service: What to Consider

When it comes to choosing a CNC Fabrication Service, there are several key factors that you need to consider. At TMC Technologies, we understand that the process can be overwhelming, and we’re here to guide you through it.

Experience with Different Materials and Complex Details

One of the first things to consider is the company’s experience with various materials and complex details. Different materials such as marble, metal, plastic, wood, and mixed materials require different techniques and expertise. A company with extensive experience in handling a wide range of materials can ensure that your product is made to the highest standards.

Moreover, dealing with complex details and advanced engineering components is an integral part of CNC fabrication. Companies with this kind of expertise, like us at TMC Technologies, can ensure that even the most intricate designs are executed with precision and quality.

Guidance Through the CNC Fabrication Process

For many, especially those who are new to CNC fabrication, the process can seem daunting. That’s why it’s crucial to choose a CNC service that can guide you through the process.

At TMC Technologies, we pride ourselves on our ability to successfully guide our clients through the CNC machining process, especially if it’s their first project. We will walk you through every step, from design to production, ensuring that you understand each phase of the process.

The Benefits of Working with a Full-Service Design and Fabrication Company

Working with a full-service design and fabrication company like us at TMC Technologies brings a host of benefits. Not only do we offer CNC services, but we also manage budgeting, design feasibility, material selection, finishing, shipping, installation, and more.

Having all these services under one roof can streamline the entire process, saving you time and reducing the hassle of dealing with multiple vendors. Additionally, it ensures that every aspect of your project is handled with the same level of expertise and attention to detail.

Moreover, a full-service design and fabrication company can provide creative solutions to complex design challenges, bringing your unique concepts to life. Whether it’s for art installations, custom signage, or innovative museum exhibits, we can make your vision a reality.

In conclusion, when hiring a CNC Fabrication Service, it’s vital to consider their experience, the guidance they offer throughout the process, and the benefits of working with a full-service company. At TMC Technologies, we check all these boxes and more, making us your ideal partner for all your CNC fabrication needs. If you’re ready to take your project to the next level, contact us today for a no-pressure consultation. We look forward to working with you!

The Future of CNC Fabrication

Peering into the crystal ball of manufacturing, it’s clear that the future of CNC fabrication is not just promising but transformative. High precision CNC machining is no longer just a tool, it’s a groundbreaking force reshaping the contours of industries across the globe.

How CNC Fabrication is Pushing the Limits of Design and Innovation

The world of CNC fabrication is ever-evolving, continually pushing the envelope of what is possible. New software advancements are enabling more complex and intricate designs to be produced with exact precision. Further, the integration of machine learning and artificial intelligence is revolutionizing the CNC machining process, allowing for predictive maintenance, real-time monitoring, and enhanced optimization.

At TMC Technologies, we are at the forefront of these technological advancements. We are harnessing the power of 5-axis CNC machines, to produce more complex parts with fewer setups and shorter lead times. This not only enhances our productivity but also results in parts with higher precision and superior surface finishes.

The Role of CNC Fabrication in the Future of Manufacturing and Other Industries

Beyond the realm of manufacturing, CNC fabrication is set to revolutionize a plethora of industries. From creating complex medical devices to intricate architectural structures, the applications are expanding at a rapid pace.

Furthermore, the impact of automation on CNC fabrication is undeniable. With the advent of robotic arms and automated tool changers, CNC machines can operate with minimal human intervention, running for extended periods, and ensuring consistent, high-quality output. At TMC Technologies, we are leveraging these advancements to deliver unparalleled service to our clients.

Moreover, the integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, is enabling a new level of connectivity and data-driven decision-making in CNC fabrication. Real-time data collection and analysis allow for improved quality control, predictive maintenance, and process optimization, further enhancing our precision, efficiency, and reliability.

Simply put, the future of CNC fabrication is not just about cutting and shaping materials. It’s about creating a world where design dreams become reality, where precision and innovation go hand in hand, and where industries can harness the power of technology to create, innovate, and inspire. At TMC Technologies, we are excited to be a part of this journey, continually investing in the latest technology and training to remain at the forefront of the CNC fabrication industry.

The future of CNC fabrication is here, and we are ready to lead the way.

Conclusion: The Unveiled Secrets of CNC Fabrication and Its Impact on Industries

As we’ve explored throughout this article, the world of CNC fabrication is a dynamic and transformative force in modern manufacturing. It’s a secret weapon that has been unveiled, allowing industries from aerospace to small-scale businesses to produce components of unparalleled precision and quality.

At the heart of this revolution is the CNC machining process, a subtractive manufacturing technique that carves out intricate designs from solid materials using computer-controlled tools. This advanced technology, combined with a variety of cutting, drilling, and grinding techniques, enables the creation of highly detailed and accurate parts.

The impact of CNC fabrication is felt across industries. In the aerospace industry, it’s a critical asset that ensures every component of an aircraft or spacecraft meets exact specifications for safety, reliability, and functionality. In small businesses, it’s a cost-effective solution for achieving the high level of precision and quality that was once only available to larger companies.

At TMC Technologies, we’re proud to be a part of this industrial revolution. Our commitment to quality, expertise in CNC machining, and ability to deliver custom solutions have made us a leader in the CNC fabrication industry. We understand the unique needs of each client and continually refine our processes to meet those needs.

Looking to the future, the role of CNC fabrication in the world of manufacturing is only set to increase. As technology continues to advance, CNC fabrication will offer even greater precision, efficiency, and possibilities for manufacturers. At TMC Technologies, we’re excited to continue evolving alongside this industry, using our knowledge and expertise to push the boundaries of what’s possible in manufacturing.

In conclusion, the mastery of high precision CNC fabrication is a fusion of advanced technology, expert knowledge, and a dedication to quality. It’s about pushing the boundaries of what’s possible and delivering parts that meet the most stringent standards of accuracy and consistency.

CNC Fabrication is no longer a secret. It’s a powerful tool that’s revolutionizing industries, shaping the future of manufacturing, and opening up endless possibilities for design and innovation. At TMC Technologies, we’re ready to help you harness the power of CNC fabrication to take your operations to the next level.

As we look forward to the future of manufacturing, we believe that the best is yet to come. With the continuous evolution of CNC fabrication techniques, the future is indeed bright. The unveiled secrets of CNC fabrication are now at the forefront of industry innovation – an exciting prospect for any company looking to enhance its processes and products.

Remember, in the world of manufacturing, precision isn’t just a goal – it’s a necessity. And with CNC fabrication, that high level of precision is within your reach. So, why not reach out to TMC Technologies today and discover how we can help revolutionize your manufacturing processes with our expertise in CNC fabrication?