Across countless industries, precision-crafted parts lay at their very heart, tirelessly powering the modern world. Yet, it is perhaps within the context of the healthcare sector that we truly understand the gravity and significance of this core machinery. Medical machining companies are the unsung heroes behind-the-scenes, operating in a realm where the slightest error could mean the difference between health and sickness, or even life and death. They play a vital role in producing the precise and reliable components that are essential in medical devices used for various treatments and procedures.

At TMC Technologies, we understand the criticality of this role and the importance of delivering top-tier quality components. We therefore commit ourselves to precision, efficiency, and reliability in every product we produce.

The precision of our machining services guarantees accurate fabrication, thus ensuring the quality and effectiveness of the resulting medical equipment. This involves producing components with a right fit, contributing directly to the overall performance and longevity of a wide range of medical devices.

The following table simplifies the key features and offering of TMC Technologies :

| Features | TMC Technologies |

| ———– | ———– |

| Range of services | Design & CAD services, Fabrication & Assembly, Precision Machining, Supply Chain Management |

| Experience | Over 20 years in the field |

| Industries served | Food processing, Industrial, Firearms, Medical, Agriculture, Aerospace/military |

| Precision | Highly accurate, detail-oriented components |

| Efficiency | Swift production time while maintaining top-notch quality |

| Reliability | Trustworthy and consistent output, meeting or exceeding client expectations |

In the world of healthcare, stakes are undeniably high. There is no room for even the tiniest error. This amplified emphasis on precision, efficiency, and reliability makes the role of medical machining companies industrially and socially crucial, a role that we, at TMC Technologies, proudly embrace.

The Importance of CNC Machining in the Medical Industry

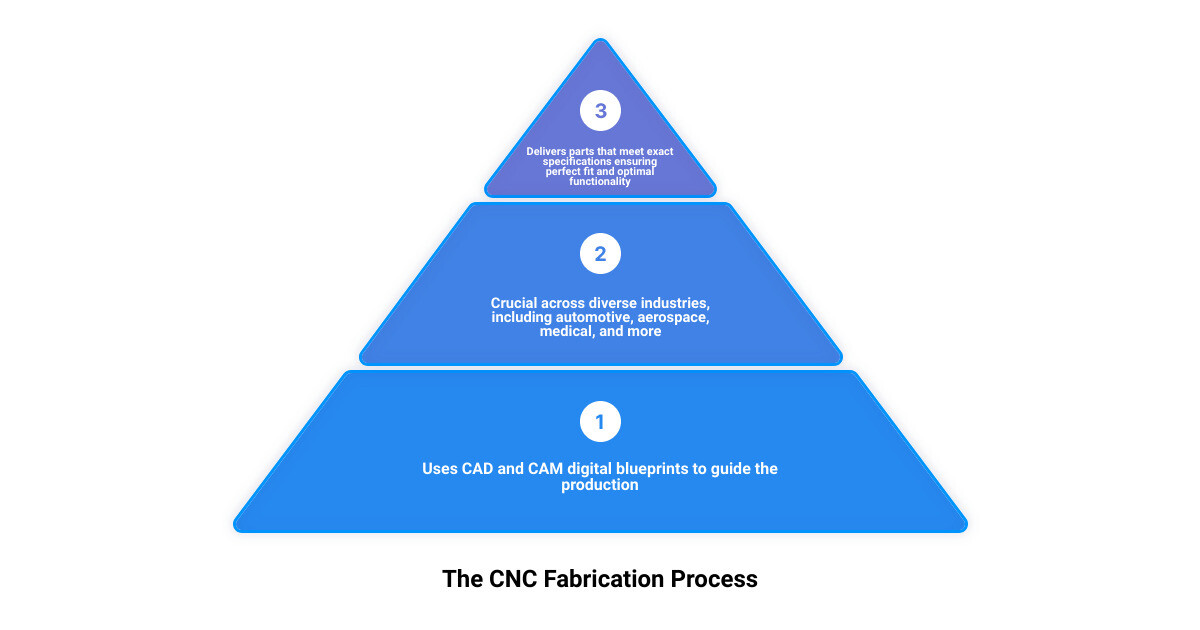

In the rapidly evolving medical sector, CNC machining has emerged as a game-changer, primarily because of its ability to produce intricate, high-quality medical components with impressive speed and accuracy.

Why CNC Machining is in High Demand in the Medical Industry

Demand for CNC machining in the medical industry is spurred by its capability to adhere to the strictest standards of precision and quality. As we’ve noted at TMC Technologies, precision and accuracy are not just requirements in the medical field; they are absolute necessities. The slightest error in the production of medical devices or surgical tools can result in significant consequences. CNC machining mitigates the risk of such errors, providing the level of precision that industries with high stakes, like healthcare, require.

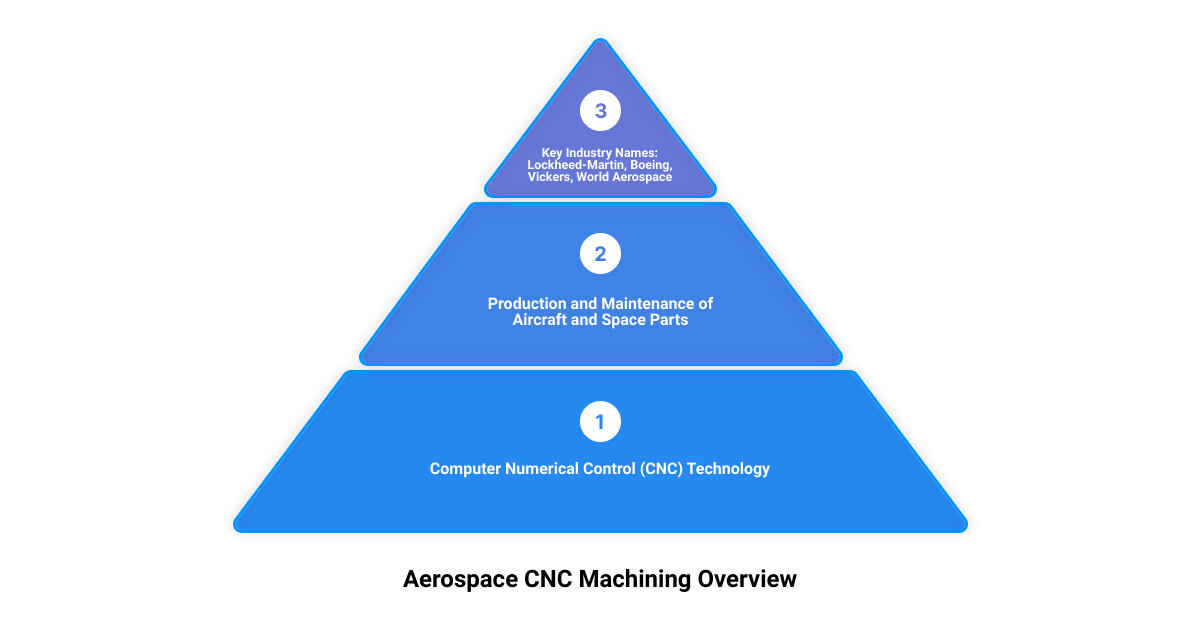

The ability of CNC machines to work with a variety of materials, including stainless steel, aluminum, and titanium, further boosts their demand. These materials are often used in the creation of durable, high-quality medical devices that can withstand the rigors of medical use.

The Benefits of CNC Machining for Medical Parts

CNC machining brings a host of benefits to the production of medical parts. A significant advantage is the process’s ability to produce parts with complex geometries and tight tolerances in high quantities. This scalability helps meet the ever-growing demand for medical devices and instruments.

Another benefit of CNC machining is its capability to maintain consistency between parts. This quality control is crucial in the medical field, where uniformity amongst components is a prerequisite.

Moreover, CNC machining minimizes waste by reducing scrap from incorrect dimensions or damaged surfaces, ensuring an efficient use of resources. As we noted earlier at TMC Technologies, it also significantly reduces the possibility of human error, enhancing overall quality control in the manufacturing process.

The Role of CNC Machining in Producing High Quantities of Parts with Tight Tolerances

CNC machining has truly revolutionized the production process in the medical industry. Its ability to produce high quantities of parts while maintaining tight tolerances makes it an invaluable tool for medical machining companies.

For instance, Swiss machines, known for their superior accuracy, are commonly used to manufacture complex medical parts such as custom pins and surgical tools. These machines, a part of the CNC family, can consistently produce parts with dimensional tolerances within ±0.0001 inches, highlighting the precision and repeatability that CNC machining brings.

At TMC Technologies, our CNC Swiss machining services, along with our CNC turning and milling, play a vital role in producing complex components with tight tolerances, thereby meeting the exacting demands of our clients in the medical industry.

In conclusion, the importance of CNC machining in the medical industry cannot be overstated. Its ability to cater to the industry’s specific needs and requirements, coupled with the precision, scalability, and consistency it offers, makes it an indispensable tool for medical machining companies.

Top Innovations by Leading Medical Machining Companies

Medical machining companies are at the heart of healthcare innovations. By creating precisely engineered components, these firms are enabling advancements in medical technology and improving patient care. Let’s delve into some of the top innovations offered by leading medical machining companies.

Ardel Engineering & Manufacturing: Specializing in Precision Medical Parts

As an ISO 9001:2015 certified and ISO 13485:2008 compliant company, Ardel Engineering & Manufacturing has carved a niche for itself in the field of precision medical parts. They have partnered with industry giants such as Medtronic and 3M, delivering unique components and complex parts as per their specifications.

Their state-of-the-art equipment, including Haas CNC machining centers and Citizen Swiss screw machines, enable them to produce components for various medical devices, from hospital equipment to blood purification systems. The company is also expanding its capabilities to produce non-implantable components and disposable items, demonstrating their commitment to evolving with the medical industry’s needs.

GF’s Medical Center of Competence: Showcasing EDM and Laser Features

GF’s Medical Center of Competence is not just a manufacturing facility; it’s where innovation happens. The company showcases EDM and laser features that could potentially revolutionize medical manufacturing. From precision milling to laser texturing, GF’s Medical Center of Competence is continuously exploring new production technologies and applications support to keep up with the ever-changing demands of the medical industry.

McCormick Industries: Offering Swiss Precision Machining for Delicate Components

McCormick Industries sets itself apart with its Swiss precision machining services. Swiss machining allows for the production of delicate and intricate components with extreme precision, a vital requirement in the medical industry. This capability enables McCormick Industries to cater to the needs of various medical applications, further solidifying their position in the medical machining industry.

H&H Machining Center: Providing High-Quality Machining for the Medical Device Industry

Located in Santa Clarita, California, H&H Machining Center is a trusted name in the medical device industry. With their expertise in CNC machining, they are able to produce small, medium, and large components with high accuracies up to ±.0001″. They offer a comprehensive range of services, from prototype to production, and cater to various medical applications including cancer detection and therapy, medical imaging, surgical devices, and more. Their rigorous quality control system ensures that each component meets or exceeds drawing specifications, underlining their commitment to accuracy and quality.

These medical machining companies are indeed driving the innovation in the medical industry with their specialized services and state-of-the-art technologies. At TMC Technologies, we aim to be part of this vanguard, striving to provide our clients with the best in precision machining services. We believe in the power of precision and in the importance of delivering quality components to drive the advancements in the medical industry.

The Role of TMC Technologies in the Medical Machining Industry

In an industry where precision, quality, and reliability are not just desired but required, TMC Technologies stands out as a beacon of excellence. Our commitment to quality and precision has made us a trusted partner for numerous industries, including healthcare.

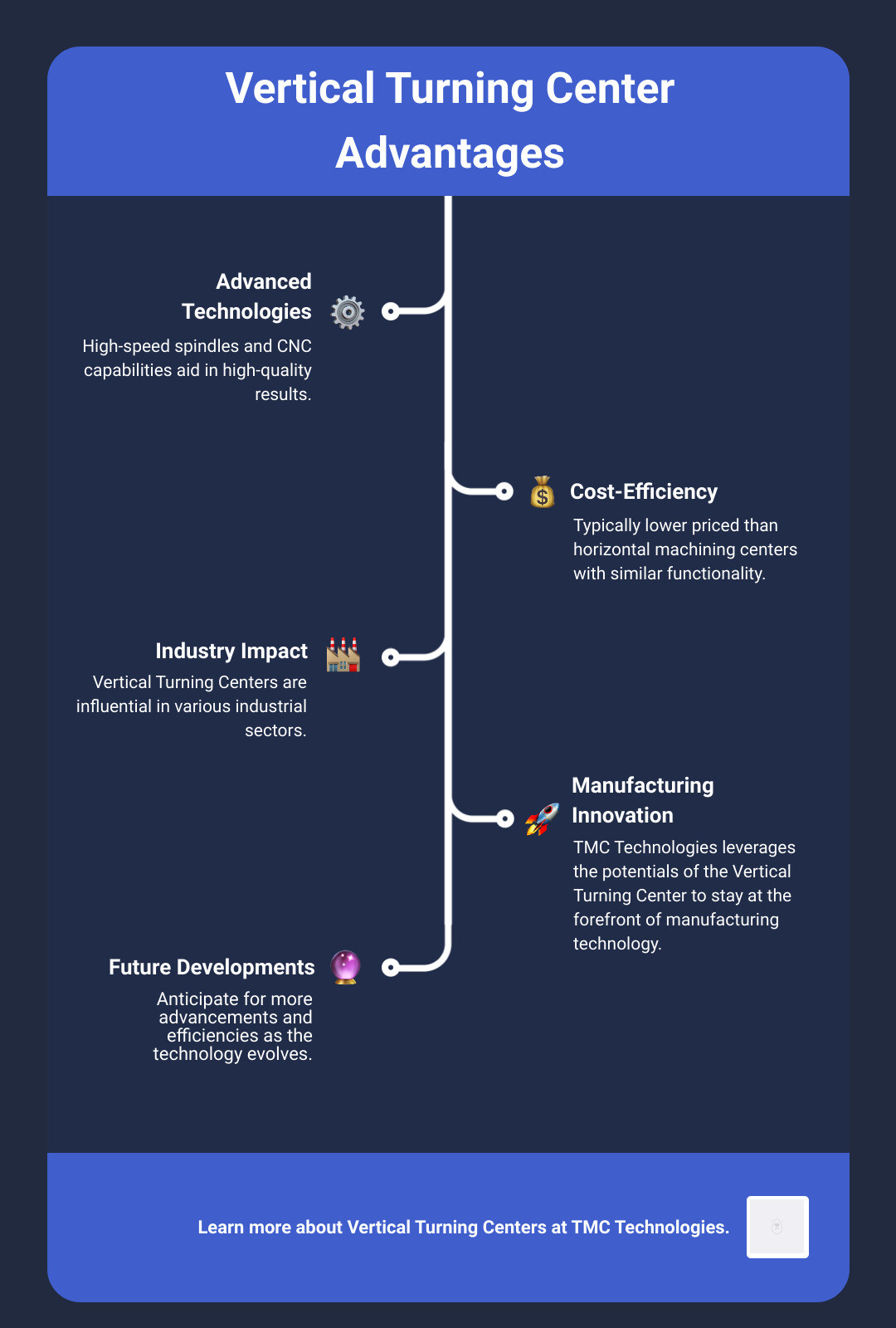

TMC Technologies: Providing High-Quality CNC Lathe Parts for Various Industries

At TMC Technologies, we specialize in providing high-quality CNC lathe parts that are crucial for a wide range of industrial machinery. In the medical industry, where even the smallest error can have serious consequences, our commitment to precision becomes even more critical. We understand that in this high-stakes arena, there is no room for compromise on the quality and accuracy of components.

Our team of highly trained machinists leverages the most advanced CNC machines to ensure that all our CNC lathe parts meet the exact requirements of our customers. These parts are meticulously crafted to meet stringent quality standards, enhancing the accuracy and longevity of your industrial machinery and helping you avoid costly repairs or replacements down the line.

Whether you’re seeking replacement parts or building new equipment, you can trust TMC Technologies to deliver CNC lathe parts that meet your strictest specifications and highest quality standards.

TMC Technologies: Offering Additional Machining Services such as Tool Design and Fabrication for Custom Applications

In addition to high-quality CNC lathe parts, TMC Technologies also offers a wide range of additional machining services. Recognizing that every client has unique needs, we provide design and fabrication services for custom applications. From CNC milling and turning to sawing, drilling, grinding, and lapping, our services are performed using state-of-the-art CNC equipment, ensuring the highest standards of quality and accuracy.

Our commitment to customization and tailored solutions further establishes our position as leaders in the precision machining parts manufacturing landscape. With TMC Technologies, you’re not just getting a supplier; you’re gaining a partner that understands your needs, values quality, and delivers precision.

In conclusion, as we navigate the complex and ever-evolving landscape of the medical industry, TMC Technologies remains steadfast in our commitment to delivering the highest quality components and machining services. We understand the unique challenges that this industry presents, and we are prepared to meet them head-on with our advanced capabilities and unwavering dedication to precision and quality. With TMC Technologies, you can rest assured that your machinery is in capable hands.

The Future of Medical Machining: Trends and Predictions

As we delve into the future of medical machining, we can see a horizon teeming with technological advancements and novel applications. The industry is set to evolve and grow in ways that will further enhance precision, efficiency, and reliability in the production of medical devices and tools.

The Impact of Technological Advancements on Medical Machining

The advent of Industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, is enabling a new level of connectivity and data-driven decision-making in CNC machining. Real-time data collection and analysis allow for improved quality control, predictive maintenance, and process optimization, further enhancing the precision, efficiency, and reliability of CNC machining processes.

At TMC Technologies, we are on the cutting edge of these advancements, integrating sophisticated technologies like machine learning and artificial intelligence in our processes. These capabilities allow us to perform predictive maintenance, real-time monitoring, and enhanced optimization, leading to higher accuracy, improved surface finishes, and fewer errors.

The future of medical machining will also see a greater emphasis on micro-machining services. These services play a crucial role in producing intricate and complex parts for various industries, including the medical and pharmaceutical sectors. Micro-machining enables us to create components with complex geometries and tight tolerances, contributing to the development of smaller, more efficient electronic devices and surgical tools.

The Role of Medical Machining in the Development of New Medical Devices and Instruments

The future of medical machining is not just about the technology; it’s also about the applications. Medical machining is instrumental in the development of new medical devices and instruments.

For instance, the growing demand for minimally invasive surgeries is pushing the boundaries for medical machining companies. These surgeries require highly precise, miniature instruments, and this is where the expertise of TMC Technologies comes in. Our micro-machining services allow us to manufacture complex medical parts such as custom pins and surgical tools with superior precision.

We also foresee medical machining playing a critical role in the burgeoning field of personalized medicine. As we move towards a more patient-centric approach to healthcare, the demand for custom-made implants and prosthetics will increase. Our precision machining capabilities enable us to meet this need, crafting custom components that fit each patient perfectly.

In conclusion, the future of medical machining is bright and holds immense potential for innovation and growth. At TMC Technologies, we are excited to be part of this journey and look forward to contributing to the advancements in this field. As we embrace and shape the technology of tomorrow, we remain committed to delivering the highest quality CNC machined parts for our clients, helping them to stay ahead in the ever-evolving medical industry.

Conclusion: The Continued Importance of Medical Machining Companies in the Healthcare Industry

As we navigate the complex terrain of the medical industry, one thing remains clear – the role of medical machining companies is more crucial now than ever before. Companies like TMC Technologies are not just manufacturers; they are partners in progress, shaping the future of healthcare with every CNC machined part.

In the face of rapid technological advancements, the demand for precision, efficiency, and reliability in the production of medical devices and tools is paramount. This is where the expertise of medical machining companies becomes invaluable. With a commitment to delivering high-quality parts that meet stringent specifications, they ensure the accuracy, longevity, and safety of medical equipment.

At TMC Technologies, we understand the importance of precision and reliability in the medical industry. Our state-of-the-art CNC machines produce high-precision parts with tight tolerances, contributing to the overall performance and safety of medical devices. We offer a range of services, from CNC lathe parts for various industries to additional machining services like tool design and fabrication for custom applications.

But beyond our services, what sets us apart is our commitment to innovation and customer satisfaction. We constantly strive to stay ahead of the curve, investing in the latest technology and training to ensure we deliver even more precise, efficient, and capable services. Our team of skilled professionals navigates the complexities of modern micro machining tools, automation, and strict regulatory guidelines, ensuring the highest quality output for our clients.

In the words of a satisfied customer from Reddit, H&H Machining, one of the top medical machining companies, is the “only machine shop I trust when prototype deadlines are short and the stakes are high, and the parts have to be perfect the very first run.” This kind of trust and reliability is what we aim to provide at TMC Technologies.

As we look to the future, the role of medical machining companies is set to grow even more. The integration of industry 4.0 technologies, such as the Internet of Things (IoT) and cloud computing, will usher in a new era of data-driven decision-making in micro machining. This, coupled with the advent of robotic arms and automated tool changers, will increase productivity while significantly reducing the risk of human error.

In conclusion, the continued importance of medical machining companies in the healthcare industry cannot be overstated. Their role in maintaining the accuracy and longevity of industrial machinery across various sectors is vital. As we stand at the precipice of an exciting new era in manufacturing, we at TMC Technologies are ready to lead the charge, delivering high-quality, precision-engineered parts that power the future of healthcare.