In the world of manufacturing, the quest for precision, efficiency, and cost-effectiveness is a never-ending journey. The advent of Computer Numerical Control (CNC) was a game-changer, but the relentless pursuit of perfection didn’t stop there. The evolution from basic CNC machines to sophisticated machining centers has revolutionized industries, offering unparalleled accuracy and productivity. Let’s delve into this exciting evolution and understand how the new machining centers are shaping the manufacturing landscape.

Since their introduction, machining centers have been constantly evolving, with manufacturers pushing the boundaries of technology to enhance their functionality and versatility. From the basic vertical machining centers (VMCs), which generally favor precision, to horizontal machining centers (HMCs), which tipped the scale towards production, each evolution has carved a niche in the manufacturing industry.

The more recent development has been the 5-axis machining center, which has significantly broadened the horizons of manufacturing by enabling the pivoting of the tool and/or the part to mill and drill at various orientations. This has not only increased productivity and geometric flexibility but also enabled the creation of complex parts with high precision.

However, the journey of evolution doesn’t end here. The introduction of new machining centers, like the TRAK VMC7si Vertical Machining Center and the 2023 GENMILL 4024 Vertical Machining Center, promise to further revolutionize the manufacturing industry. These new entrants are set to redefine the benchmarks of precision, productivity, and cost-effectiveness.

In this article, we will explore these new machining centers, their impact on the manufacturing industry, and how they are changing the game in the world of CNC machining. We will also look at the role of leading players, like Okuma and TMC Technologies, in this exciting evolution. So, if you are a manufacturing company in need of top-tier quality CNC lathe parts, looking for reliable suppliers, or simply interested in understanding the future of machining centers, stay tuned!

This is the beginning of a deep dive into the world of new machining centers and how they are revolutionizing the industry.

The New TRAK VMC7si Vertical Machining Center: A Game Changer

In a world where precision, efficiency, and reliability are paramount, the new TRAK VMC7si Vertical Machining Center stands out as a game-changer in the manufacturing industry.

Key Features and Specifications of the TRAK VMC7si

The TRAK VMC7si is equipped with a Sinumerik One control system that includes a handwheel run option and One Dyanamics-Surfacing. This advanced control system vastly improves the machine’s efficiency and precision.

The machining center boasts of a table size of 35.43″ x 19.69″, and an axis travel of 30″ in X, 20″ in Y, and 20″ in Z. It offers five T-slots and can handle a maximum workpiece weight of 1,230 LBS. The minimum and maximum spindle nose to table distance is 3.5″ and 23.5″ respectively.

The VMC7si features a #40 spindle taper and a spindle speed range of 10-12,000 RPM, powered by a robust 41.5 HP spindle motor. The tool holder type is CAT 40, and the spindle nose diameter is 3″. The machine comes with a spindle cooler with a capacity of 1 gallon.

This vertical machining center has a footprint of 144″ x 112″ x 108″ and weighs 8,710 LBS.

The Impact of the TRAK VMC7si on the Manufacturing Industry

The TRAK VMC7si Vertical Machining Center is not just a machine; it’s a revolution in the manufacturing industry. This state-of-the-art CNC machine offers unprecedented levels of precision, speed, and efficiency, which directly translate to increased productivity and reduced costs for businesses.

The Sinumerik One control system simplifies complex machining tasks, allowing manufacturers to produce high-quality components at a faster pace. Its advanced features, such as the handwheel run option and One Dyanamics-Surfacing, offer manufacturers greater control over the production process, leading to improved accuracy and fewer errors.

Moreover, the robust build and high load capacity of the TRAK VMC7si enable it to handle a wide range of materials and large-scale projects. This versatility makes it an invaluable asset for businesses across various sectors, from aerospace and automotive to medical and industrial manufacturing.

In conclusion, the TRAK VMC7si is more than just a new machining center; it’s a powerful tool that’s set to redefine the future of manufacturing. By leveraging its advanced features and capabilities, manufacturers can stay ahead of the curve, delivering high-quality products faster and more efficiently.

The Role of Okuma in the CNC Machining Center Industry

Over the years, Okuma has established itself as an industry leader in the CNC machining center industry, offering innovative solutions designed to enhance productivity, improve performance, and facilitate smart manufacturing.

Overview of Okuma’s Product Range and Services

Okuma’s product lineup is nothing short of impressive, offering a range of machining centers that cater to different industry needs. From lathes, multitasking centers, 5-axis machines, double columns, grinders to hybrid machines, Okuma’s portfolio is vast. Their machining centers are known for their high precision and cutting-edge technologies, such as the Thermo-Friendly Concept, Collision Avoidance System, and 5-Axis Auto Tuning, which enhance machine performance.

Beyond their robust product catalogue, Okuma also provides a plethora of services aimed at maximizing machine tool productivity and longevity. These include services like training through the Okuma Machine Tool Academy, application engineering and machine option engineering services, and a comprehensive range of service programs. Okuma’s commitment to customer care is evident through their offerings such as the Okuma CARE Kit and the provision of both new and repaired parts.

How Okuma’s Machining Centers are Transforming Industries

Okuma’s machining centers are not just tools; they are catalysts for industry transformation. By leaning on advanced technologies, Okuma’s machining centers help businesses optimize their operations, improve efficiency, and reduce downtime.

The Thermo-Friendly Concept, for instance, minimizes thermal deformation, maximizing accuracy and stability even during long runs. The Collision Avoidance System and Machining Navi aid in achieving error-free operation, while the 5-axis Auto Tuning system maintains precision in five-axis machining.

Furthermore, Okuma’s automation systems, underpinned by the Connect Plan, provide visibility of the plant floor, helping businesses identify actionable insights for increased profitability. The Connect Plan Lite allows businesses to monitor operating history, production rates, and alarm history on a single machine, further improving process transparency.

In summary, Okuma’s role in the CNC machining center industry is pivotal. By offering a comprehensive range of advanced machining centers and customer-centric services, Okuma is helping to shape the future of manufacturing, enabling businesses to stay competitive in an ever-evolving industrial landscape.

The 2023 GENMILL 4024 Vertical Machining Center: A Look into the Future

As we gaze into the future of machining centers, one machine stands out as a beacon of innovative design and cutting-edge technology: the 2023 Expand Machinery GENMILL 4024 Vertical Machining Center. With its unique features and specifications, the GENMILL 4024 is not just a tool for modern manufacturers, but a harbinger of the future for the entire machining center industry.

Unique Features and Specifications of the GENMILL 4024

The GENMILL 4024 sets itself apart with an array of remarkable features that enhance productivity, precision, and ease of use. Starting with the Mitsubishi M830 CNC Control, it provides an intuitive and user-friendly interface for operators. The machine also boasts a 40 station ATC Upgrade, which means more tools are readily available for the machine to use, thereby reducing downtime and improving efficiency.

Furthermore, the GENMILL 4024 comes with a Detron 8″ Trunnion and a Renishaw Probe Set, both of which contribute to the machine’s superior precision and accuracy. The machine also features a 12,000 RPM Direct-Drive Beltless Spindle, which not only enhances its speed but also minimizes vibration and noise, leading to smoother operations and better quality results.

In terms of power, the GENMILL 4024 is a force to be reckoned with. It has a 25 HP S3 Power 20HP 30-Min Spindle Motor, delivering ample power for heavy-duty machining tasks. This machine is also designed for maximum versatility, with a spacious table size of 45.66″ x 19.68″ and rapid traverse rates of up to 1,417 IPM on the X and Y axes.

The Potential Impact of the GENMILL 4024 on Future Manufacturing

The GENMILL 4024 is more than just a state-of-the-art piece of machinery; it represents a paradigm shift in manufacturing. Its advanced features and capabilities could potentially revolutionize the way manufacturers approach their machining tasks, offering unprecedented levels of precision, speed, and flexibility.

With its 40 station ATC and high-speed spindle, the GENMILL 4024 could significantly reduce production times, leading to increased throughput and profitability for manufacturers. Its advanced CNC control system and versatile design also make it highly adaptable, enabling manufacturers to easily switch between different projects and materials.

Moreover, the GENMILL 4024’s emphasis on precision and accuracy could lead to improved quality control in manufacturing. By minimizing errors and inconsistencies, manufacturers could produce higher quality parts, leading to increased customer satisfaction and brand reputation.

In conclusion, the 2023 Expand Machinery GENMILL 4024 Vertical Machining Center is not just a machine, but a vision of what future manufacturing could be. Its advanced features and capabilities could potentially revolutionize the industry, setting a new benchmark for precision, speed, flexibility, and quality in machining centers.

Understanding the Cost of Machining Centers

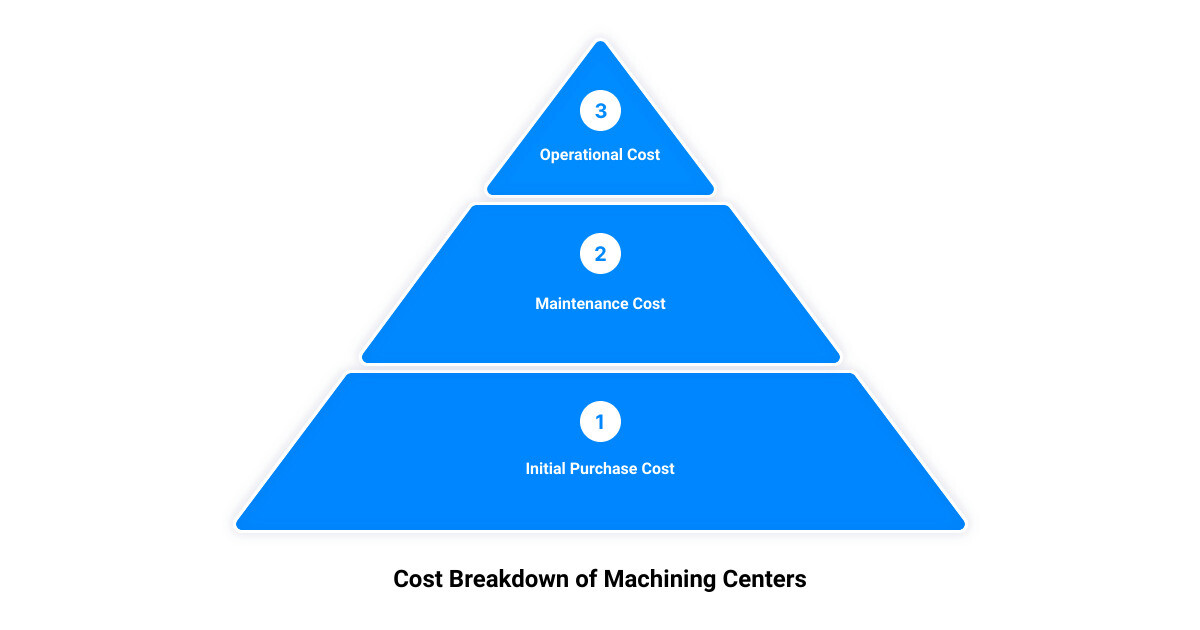

Navigating the intricate landscape of machining centers can be a daunting task, especially when it comes to understanding their cost. Let’s break down the financial investment involved in procuring and operating these essential tools for manufacturing.

The Cost of a VMC and Factors Influencing It

Acquiring a Vertical Machining Center (VMC), a type of CNC machine, is a significant investment for any manufacturing entity. The price of a VMC is influenced by a range of factors including the machine’s capabilities, size, brand, and the technology it incorporates. As a general rule of thumb, VMCs can be priced anywhere between Rs. 1000000 to Rs. 3000000. However, it’s important to consider that this is a wide range and the final cost can vary significantly based on the specific needs and preferences of your operations.

Choosing a VMC requires a careful evaluation of your project requirements, budget constraints, and the potential return on investment. As with any substantial asset acquisition, it’s vital to balance upfront costs with long-term value. For instance, a high-quality VMC from a reputed brand might have a higher initial cost but could offer superior performance, longevity, and lower maintenance costs over time.

The Hourly Cost of Machining and What It Means for Businesses

Beyond the initial purchase price, it’s essential to consider the running costs associated with operating a machining center. This is often calculated as an hourly rate and can significantly impact the overall cost-efficiency of your manufacturing operations.

The hourly cost of machining generally ranges from $35 – $40 per hour for 3-axis machining. In contrast, multi-axis machining, which offers higher precision and complexity, can cost between $75 – $120 per hour. This cost includes factors such as machine depreciation, maintenance, energy consumption, and labor.

Understanding the hourly cost of machining is essential for businesses to accurately calculate project costs and set pricing for products or services. By optimizing machine usage and improving efficiencies, businesses can lower their hourly costs, enhancing profitability, and competitiveness in the marketplace.

In conclusion, understanding the cost of machining centers, both in terms of initial investment and ongoing operation, is crucial for making informed decisions that align with your business goals. It’s about striking the right balance between cost-efficiency and performance to ensure your manufacturing operations thrive in a competitive industry.

The Difference Between CNC and Machining Centers, and VMC and HMC

Navigating the world of machining can often seem like a maze of acronyms and industry-specific jargon. However, understanding the difference between CNC and machining centers, as well as between vertical machining centers (VMC) and horizontal machining centers (HMC), is crucial for making informed choices about your manufacturing needs.

CNC vs Machining Center: What Sets Them Apart?

At first glance, CNC (Computer Numerical Control) and machining centers may seem indistinguishable. After all, they both involve the use of computer-controlled machinery for precision manufacturing. However, their differences lie in their specific applications and capabilities.

CNC is a broader term that refers to the use of computers to control machine tools, allowing for extreme precision and consistency in manufacturing. This can be applied to a wide range of equipment, including lathes, mills, routers, and grinders.

On the other hand, a machining center is a specific type of CNC machine that includes an automatic tool changer and a table that clamps the workpiece in place. What sets machining centers apart is their ability to perform multiple types of operations, such as milling and drilling, without the need to manually switch tools or reposition the workpiece. This increases productivity and reduces the margin for error.

VMC vs HMC: Understanding Their Unique Characteristics

When it comes to machining centers, the main distinction is between vertical and horizontal orientations. Vertical machining centers (VMCs) and horizontal machining centers (HMCs) differ primarily in how the spindle, the part of the machine that holds the cutting tool, is oriented.

In a VMC, the spindle is oriented vertically, which is generally more suited for precision work. The vertical orientation allows gravity to help with chip evacuation, which can result in a superior surface finish.

On the other hand, an HMC has a horizontally oriented spindle. This configuration is generally better suited for production work, as it allows for quicker chip removal and less deflection, thereby increasing efficiency and reducing wear on the machine. It also allows for uninterrupted machining during a pallet change, which can significantly boost productivity in high-volume production settings.

Understanding these differences can help you make the right choice for your specific manufacturing needs. Whether it’s the broad application of CNC, the multi-functionality of machining centers, or the specific advantages of VMCs and HMCs, each has its own role to play in revolutionizing the manufacturing industry.

Conclusion: The Future of Machining Centers and Their Role in Industry Revolution

In the grand tapestry of manufacturing, the threads of innovation and precision are woven tighter each day. As we stand on the brink of a new era in industrial manufacturing, one thing is abundantly clear – the future of machining centers is not just bright, but transformative.

Machining centers, whether they’re CNC, VMC, or HMC, have long ceased to be mere tools of production. Today, they are catalysts of change, driving efficiencies, precision, and innovation at an unprecedented scale.

Machining Centers: The Efficient Engines of Tomorrow

As we saw with the advancements in the TRAK VMC7si and the 2023 GENMILL 4024, machining centers are becoming more efficient, flexible, and precise. They’re not just reshaping the manufacturing landscape, but redefining it. With their ability to handle complex geometries, reduce manual intervention, and deliver consistent high-quality output, they are set to become the engines of the future’s smart factories.

The Role of Automation and Data in Machining Centers

But it’s not just about hardware. The rise of data-driven manufacturing and automation is adding a new layer of capability to these machining centers. Companies like Okuma and TMC Technologies are integrating advanced software, sensors, and automation into their offerings, leading to smarter, more capable machining centers. This marriage of hardware and software is not just enhancing productivity but also paving the way for predictive maintenance, real-time monitoring, and more streamlined supply chains.

The Economic Impact of Machining Centers

Beyond productivity and precision, the economic impact of these advanced machining centers cannot be ignored. With lower operating costs, faster turnaround times, and higher quality output, they are revolutionizing the cost dynamics in the manufacturing industry. This is enabling businesses to become more competitive, agile, and responsive to market demands.

The Future is Now

The future of machining centers is not a distant dream, it’s happening right now. As we peer into the horizon of the manufacturing industry, we see a landscape transformed by the power of these advanced machines. From aerospace to medical, automotive to agriculture, no industry will remain untouched by this revolution.

In conclusion, machining centers are not just shaping the future of manufacturing, they are the future. They stand at the intersection of technology and industry, weaving a new era of precision, efficiency, and innovation. As we forge ahead into this exciting new era, one thing is clear – the revolution is not just coming, it’s already here. And it’s powered by machining centers.