As the industrial landscape continues to evolve with the advent of advanced machinery and automation, manufacturers are constantly on the lookout for equipment that offers precision, efficiency, and versatility. Enter the world of the CNC Precision Automatic Lathe – a game-changing piece of machinery that has revolutionized the manufacturing sector.

Also known as a Swiss-type automatic lathe, the CNC Precision Automatic Lathe is a high-tech piece of equipment that combines the power of computer numerical control (CNC) technology with the efficiency of an automatic lathe. This lathe is a master of precision machining, capable of performing complex tasks such as turning, milling, drilling, boring, tapping, and engraving in a single operation. It’s designed to handle batch processing of precision hardware and special-shaped non-standard shaft parts with astonishing accuracy and speed.

Manufacturers across various industries depend on this extraordinary machine to produce parts with exact specifications. Whether it’s for automotive components, aerospace parts, medical devices, or intricate firearms, the CNC precision automatic lathe delivers impeccable results every time. Its ability to streamline the manufacturing process, reduce errors, and increase production speed make it an invaluable asset in any manufacturing operation.

In the following sections, we will delve deeper into the evolution, precision, distinction, application, and advantages of the CNC Precision Automatic Lathe. We will also highlight the services offered by TMC Technologies – a leading provider in the field of CNC lathe shops. So, let’s unlock the excellence of the CNC Precision Automatic Lathe and explore how it’s shaping the future of manufacturing.

The Evolution of CNC Precision Automatic Lathe

Origin and Development of CNC Precision Automatic Lathe

Peeling back the layers of history, we discover that the CNC Precision Automatic Lathe machine, originally known as the Swiss-type automatic lathe, had its roots in Switzerland and Germany. In its infancy, this machine was primarily used for the precision machining of military equipment. Over time, the industrialization process expanded, leading to a growing market demand for this type of machinery. This demand catalyzed the adaptation of the Swiss-type automatic lathe machine for processing civilian products.

The development of similar CNC precision automatic lathe machines in Japan and South Korea predates that of China. Initially, these machines were used predominantly in the military industry. Post-war, they were widely adopted in the manufacturing industry to meet the growing developmental needs.

The Growth of CNC Precision Automatic Lathe in China

China’s journey with the CNC Precision Automatic Lathe began a bit later. Technical closure and policy restrictions meant that, prior to the 1990s, China’s Swiss-type automatic lathe relied heavily on imports to satisfy processing needs. However, the continuous development of automation and the burgeoning market demand led to the emergence of a multitude of powerful CNC machine tool manufacturers in the Chinese market.

Regions such as Guangdong, Jiangsu, Nanjing, Shandong, Liaoning, and mainland Xi’an became hubs for the production of this series of machine tools, filling the domestic gap. This growth in manufacturing was a result of the increasing market demand and the urgent need for domestic production capacity.

Today, these machines play a critical role in various industries, providing parts integral to the functionality and longevity of a wide range of machinery. Their evolution has been marked by a significant leap in processing efficiency and accuracy. This has been made possible due to their two-axis arrangement of tools, which greatly reduces the processing cycle time, and the ability to equip these machines with an automatic feeding device, thereby fully automating production and reducing labor costs and product defect rates.

As we delve deeper into the world of CNC Precision Automatic Lathes, we will continue to explore the precision, distinction, application, and advantages of these machines, as well as how companies like TMC Technologies are leveraging this technology to deliver excellence in the manufacturing industry.

Understanding the Precision of CNC Precision Automatic Lathe

Precision is a term that’s thrown around a lot in the manufacturing industry, but what does it truly mean in the context of a CNC Precision Automatic Lathe? Understanding this key attribute is essential for any manufacturing company that values top-tier quality components and the longevity of their machinery.

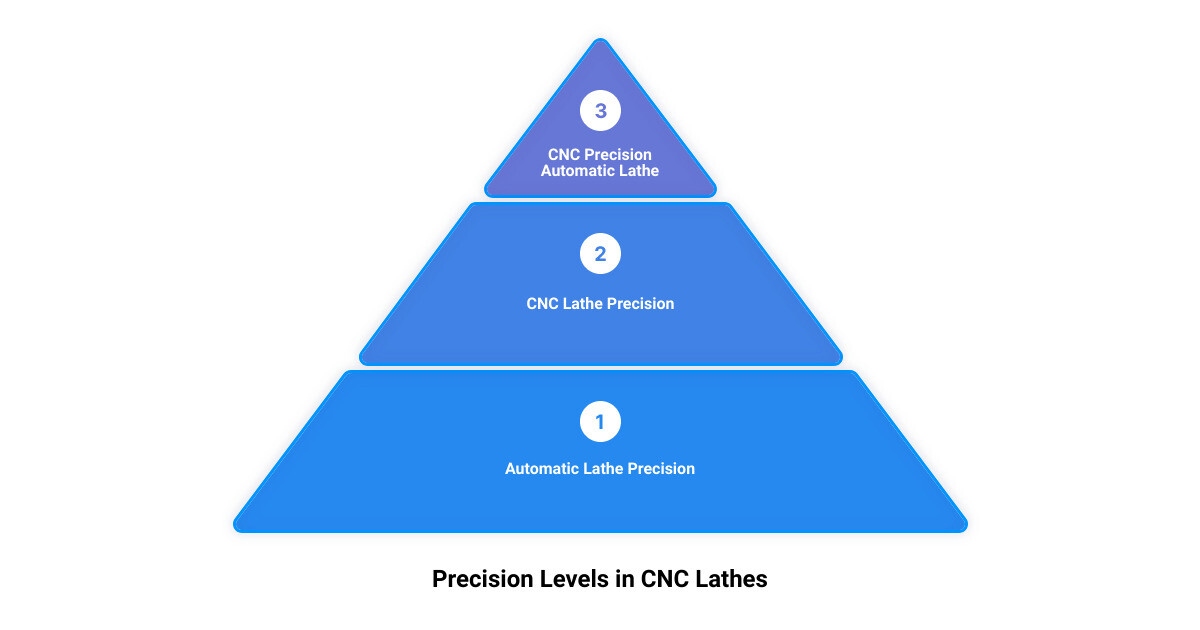

The Precision of Automatic Lathe

An automatic lathe, or CNC automatic lathe to be precise, is a highly sophisticated machine designed for precision machining. The processing accuracy of automatic CNC lathe machine manufacturers can generally reach 0.05-0.1MM. This means that the components produced by these machines are virtually flawless and perfectly measured. Each part is crafted to meet exact specifications, eliminating errors and reducing waste. This level of precision is highly sought after in various industries, where even the smallest deviation can lead to significant implications.

The Precision of a CNC Lathe

When we talk about the precision of a CNC lathe, we’re referring to its ability to deliver high-quality parts with tight tolerances. In the world of precise machining, the CNC lathe stands out for its ability to meet tolerances typically ranging from ±0.0002” (±0.00508 mm) to ±0.0005” (±0.0127 mm). This means that the CNC lathe can produce parts with a high degree of part complexity and precision. This is particularly important in industries such as aerospace and automotive, where component accuracy is absolutely critical.

The Accuracy of a CNC Lathe

It’s important to understand that precision and accuracy, while related, are not the same. The accuracy of a CNC lathe refers to how closely the machine can hit the target value. In other words, if a CNC lathe has a tolerance of +/- 0.01 mm, it means that the machining tool can introduce a deviation of 0.01 mm in every cut. This deviation can be either 0.01 mm extra than the standard value, or less than 0.01 mm by the standard value. This level of accuracy ensures that the final product matches the original design as closely as possible.

In conclusion, the precision and accuracy of a CNC Precision Automatic Lathe lie at the heart of its value in the manufacturing sector. By delivering components that meet exact specifications and tolerances, these machines guarantee high-quality outputs, thus enhancing the functionality and longevity of the end product. This level of precision and accuracy are key factors in why companies like TMC Technologies trust in the capabilities of CNC Precision Automatic Lathes.

The Distinction Between CNC Lathe and Automatic Lathe

Step into the world of precision machining and you’ll find a diverse array of equipment, each boasting unique capabilities and features. Two of the stars in this high-tech arena are CNC lathes and automatic lathes. While they may seem similar at first glance, they have distinct differences and unique roles in the manufacturing process.

The Difference Between CNC Lathe and Automatic Lathe

The essence of CNC lathes lies in their ability to produce complex parts with a high degree of accuracy. These machines are controlled by computer programs allowing for precise repeatability in the manufacturing process. CNC lathes can handle a wide range of materials and offer a variety of surface finishing options. They’re capable of maintaining tight tolerances, typically ranging from ±0.0002” (±0.00508 mm) to ±0.0005” (±0.0127 mm).

On the other hand, automatic lathes, also known as Swiss-type automatic lathes, are also precision machining equipment. They are typically used for the high-volume production of small parts and can achieve processing accuracy of 0.05-0.1MM. However, the term “automatic”, when used in the machining industry, often refers implicitly to cam-operated machines.

While all CNC machine tools are automatic, the term “automatic lathe” does not routinely refer to 2-axis CNC lathes, even if they are fully automated.

The Role of Automation in CNC Lathes

Automation is the heart and soul of CNC lathes. Driven by computer programs, these machines can operate with minimal human intervention, which not only boosts productivity but also reduces the risk of manual errors.

A CNC lathe can introduce a deviation of as little as 0.01 mm in every cut, ensuring a high degree of consistency and precision. This level of control is what makes CNC lathes an invaluable asset in industries where even the slightest deviation can lead to significant consequences.

In conclusion, while both CNC and automatic lathes have a role to play in the world of precision machining, it’s the level of automation and control that sets them apart. By understanding their unique capabilities, manufacturers can choose the right tool for their specific needs, ensuring optimal efficiency and quality in their products.

The Application and Advantages of CNC Precision Automatic Lathe

Unlocking the doors to a world of precision and efficiency, the CNC Precision Automatic Lathe has become a sought-after solution in the manufacturing landscape.

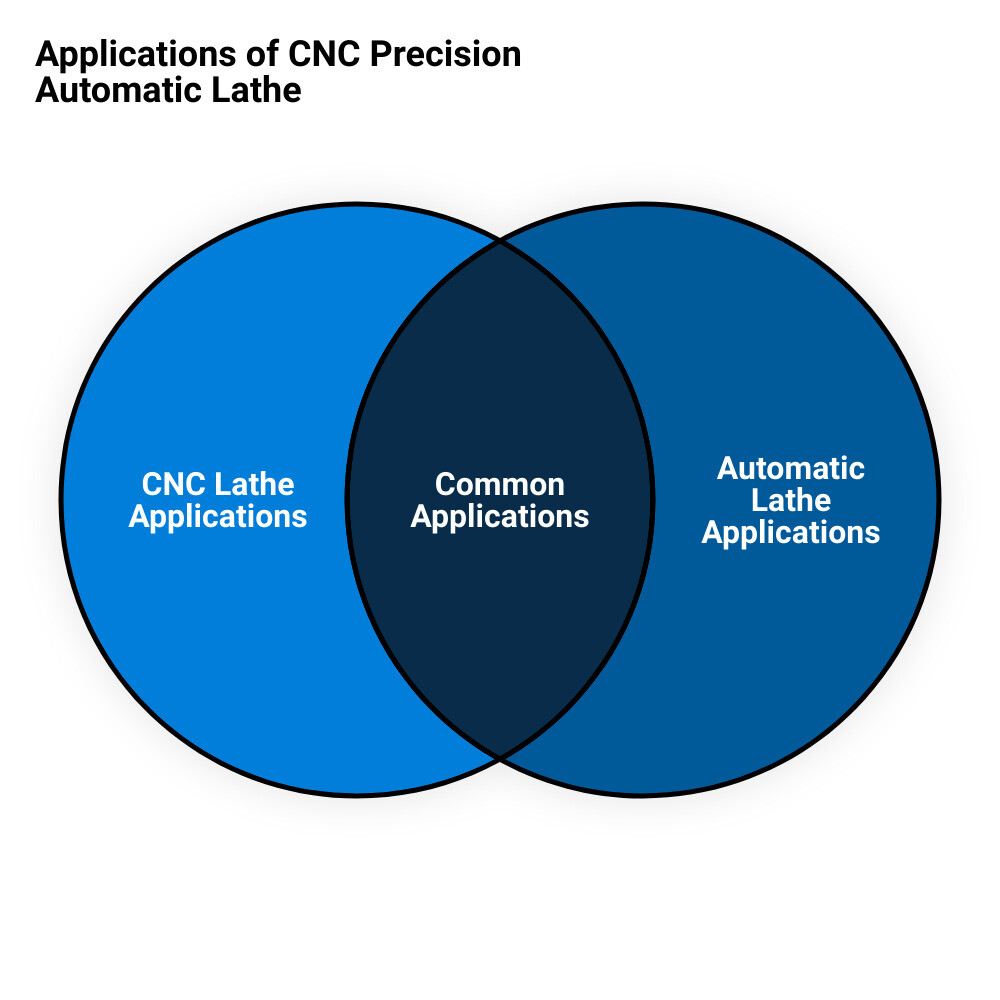

The Use of CNC Precision Automatic Lathe in Various Industries

The CNC Precision Automatic Lathe, also known as the Swiss-type automatic lathe, is a versatile piece of equipment that is utilized across a wide spectrum of industries. This includes the automotive sector for the production of car parts, the medical industry for creating intricate devices, and the aerospace field for manufacturing components to exact specifications. The lathe’s ability to accurately execute complex operations such as turning, milling, drilling, boring, tapping, and engraving makes it an indispensable asset in the production line.

The Swiss-type automatic lathe serves as a practical solution for the batch processing of precision hardware and non-standard shaft parts. This versatility is further amplified by the lathe’s capability to work with an array of materials including stainless steel, aluminum, and production-grade polymers.

The Benefits of Using CNC Precision Automatic Lathe

The CNC Precision Automatic Lathe brings a plethora of advantages to the table. One of its standout features is its capacity to significantly reduce setup time. By eliminating the need for workpiece repositioning or tooling angle adjustments, this machine increases efficiency and keeps the production line moving smoothly. This translates into quicker component delivery which addresses a major pain point for manufacturing companies.

In terms of precision, the CNC Precision Automatic Lathe truly shines. With its ability for precise positioning and orientation of the workpiece during machining, it ensures consistent accuracy across all surfaces. Furthermore, the tool maintains the correct cutting angle relative to the workpiece orientation, leading to a superior surface finish. This eliminates the need for rework or manual finishing operations, saving time, and resources, while guaranteeing that components meet the highest quality standards.

The CNC Precision Automatic Lathe also introduces a new level of versatility to CNC lathes. It can perform tasks traditionally associated with milling machines, such as complex machining operations, cross-drilling, cross-milling, and angled features. This expanded range of operations allows for a broader scope of work to be undertaken on a single machine.

In summary, the benefits of using the CNC Precision Automatic Lathe extend beyond just precision. It’s about efficiency, versatility, and the quality of the final product. These features make it an invaluable tool for companies like TMC Technologies, who are committed to delivering the best in CNC machining services.

TMC Technologies: Delivering Excellence in CNC Precision Automatic Lathe

Overview of TMC Technologies

In the realm of precision machining, TMC Technologies emerges as a formidable force, setting a new benchmark for excellence with its state-of-the-art CNC Precision Automatic Lathe services. With more than three decades of experience, the company has mastered the art of precision machining, carving out a niche for itself in the highly competitive landscape of aerospace components manufacturing.

TMC Technologies’ reputation is built on its consistent delivery of high-quality services, making it a leader in CNC lathe parts manufacturing. The company’s team of highly trained engineers and technicians use the latest machining technologies such as 3D modeling, CNC turning, and machining to ensure accuracy and superior workmanship.

Moreover, the company’s deep understanding of the strict protocols and regulations of the aerospace industry is a testament to their dedication to upholding the highest quality standards in manufacturing CNC lathe parts.

The Unique Selling Proposition of TMC Technologies

What sets TMC Technologies apart is its holistic approach to precision machining services. Beyond high-quality manufacturing, the company offers an extensive range of services that include grinding, heat treating, light fabrication/assembly, and other secondary operations.

TMC Technologies also excels in using cutting-edge automated tools and technology, enabling them to manufacture a variety of materials, including aluminum alloys, brass, titanium, stainless steel, and plastics, in an efficient and cost-effective manner.

In a fast-paced industry where time is of the essence, TMC Technologies recognizes the importance of quick turnarounds. Therefore, they strive to deliver short lead times without compromising on the high-quality workmanship they are known for.

Above all, TMC Technologies’ unwavering commitment to customer satisfaction sets them apart. Their meticulous attention to detail and dedication to quality ensures that clients can rely on them to fulfill their machining needs to the highest standards.

In essence, the unique selling proposition of TMC Technologies lies in their blend of extensive industry experience, cutting-edge technology, rigorous quality control, and a commitment to customer satisfaction. This powerful combination makes them a trusted partner in the world of precision aerospace machining.

Conclusion: The Future of CNC Precision Automatic Lathe

As we usher in a new era of advanced manufacturing, the future of CNC Precision Automatic Lathes glows with promise. The industry’s steady march towards automation, precision, and efficiency is being spearheaded by trailblazers like TMC Technologies. Their commitment to delivering excellence in every component, along with their embrace of the latest in technological advancements, sets the stage for a future where CNC Precision Automatic Lathes play an increasingly critical role in diverse industries.

The integration of machine learning, artificial intelligence, and Industry 4.0 technologies into CNC machining processes is expanding the horizons of what these machines can do. Predictive maintenance, real-time monitoring, enhanced optimization, and data-driven decision-making are just the tip of the iceberg. The rise of 5-axis CNC machines is transforming the industry, enabling the production of more complex parts with fewer setups and shorter lead times. This translates into higher productivity, fewer errors, improved surface finishes, and significant cost savings.

Moreover, the adoption of C Axis milling and its growing importance in modern manufacturing underscores the versatility and precision of CNC lathes. The ability to perform simultaneous multi-axis machining, reduce setup time, increase accuracy, and enhance surface finish are compelling reasons why CNC Precision Automatic Lathes are quickly becoming the new standard in manufacturing.

TMC Technologies, with their advanced 3 and 4 axis CNC machining capabilities and their dedication to customer satisfaction, is leading the way in this exciting journey. Their investment in the latest technology and training ensures that they remain at the forefront of the high precision CNC machining industry, poised to meet the rising demand for CNC Precision Automatic Lathes.

In conclusion, the future of the CNC Precision Automatic Lathe is not only bright but also crucial in driving the next wave of manufacturing excellence. As we look forward to the advancements that lie ahead, companies like TMC Technologies are prepared to unlock new levels of precision, efficiency, and innovation, ensuring their clients stay at the cutting edge of their respective industries.