From the intricate components that make up the engines of commercial aircraft to the high-strength, lightweight parts of advanced spacecraft, every element in the aerospace industry shares a common factor: the relentless demand for precision. Welcome to the world of aerospace CNC machining, where precision is not just a goal, but an absolute necessity.

Aerospace CNC machining is the backbone of the aerospace industry, playing a pivotal role in the production of high-precision components that conform to strict international quality standards. This sophisticated manufacturing process combines the power of computer numerical control (CNC) technology with advanced machining techniques to create intricate parts and assemblies essential for the functionality, safety, and reliability of modern aircraft and spacecraft.

Whether it’s the manufacturing of complex geometries for airplane parts or the production of highly specialized components for eVTOL aircraft and spacecraft, aerospace CNC machining provides the expertise and aptitude required to achieve flawless outcomes. In this industry, there’s zero room for error. Even the tiniest deviation can have catastrophic consequences, making the high precision and accuracy delivered by aerospace CNC machining paramount.

Stay with us as we delve into the fascinating world of aerospace CNC machining, exploring its role in the aerospace industry, the process itself, the materials used, and its impact on the future of aerospace technology.

Understanding the Role of CNC Machining in the Aerospace Industry

As we embark on this exploration of aerospace CNC machining, we start by understanding its central role in the aerospace industry. This technology is a vital cog in the complex machinery of the aerospace sector, with its precision and accuracy being non-negotiable. Let’s explore why precision is of such importance and how CNC machining fits into the overall aircraft construction and space travel ecosystem.

The Importance of Precision in Aerospace CNC Machining

In the world of aerospace manufacturing, the phrase “close enough” is non-existent. With lives and millions of dollars at stake, every part created must meet the highest industry standards. The aerospace industry is notorious for its stringent safety controls and high production standards for CNC machining aerospace parts. As such, there is zero-tolerance for any dimensional errors or performance inconsistencies.

Precision machining in aerospace enables manufacturers to shape large pieces of material into more precise parts using computer numerical control (CNC) equipment. CNC machining plays a critical role in meeting these exact specifications, with the ability to produce complex components that adhere strictly to the precise dimensions, tolerances, and performance requirements of the aerospace industry.

Moreover, CNC machines can achieve tolerances up to 0.002 mm using aerospace-grade metals and plastics. This level of precision is crucial to ensure that the components do not fail in flight. A single faulty or imperfect component can lead to a loss of thousands of dollars in aircraft and space stations, not to mention the potential for catastrophic consequences.

The Role of CNC Machining in Aircraft Construction and Space Travel

CNC machining has found its place in nearly every step of aircraft construction and space travel, from the tiniest internal components to the major exterior parts of an aircraft or spacecraft. The process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles, using kits, components, and assemblies essential for crafts used in the aerospace industry.

CNC machining allows for the production of various aircraft parts, ranging from bushings, hinges, and clamps to custom parts, all meeting the highest quality standards. Whether it’s for commercial aircraft, eVTOL aircraft, or spacecraft, CNC machining ensures that these components function properly without posing any form of danger.

In the realm of space travel, the role of CNC machining becomes even more significant. Space shuttles and their components must withstand extreme conditions, from fluctuating temperatures to high-pressure environments. CNC machining creates parts designed to endure these harsh environments, ensuring the safety and success of space missions.

In conclusion, aerospace CNC machining is a critical player in the aerospace industry, ensuring the safety, reliability, and efficiency of aircraft and spacecraft. Its role in creating high-precision, quality parts is undeniable, and as aerospace technology continues to advance, the importance of precision machining in this industry will only grow.

The Process of Aerospace CNC Machining

When it comes to aerospace manufacturing, precision is the name of the game. The process of aerospace CNC machining taps into the power of computer-aided tools and carries out major operations like precision CNC milling and precision CNC turning. Let’s delve into these areas in more detail.

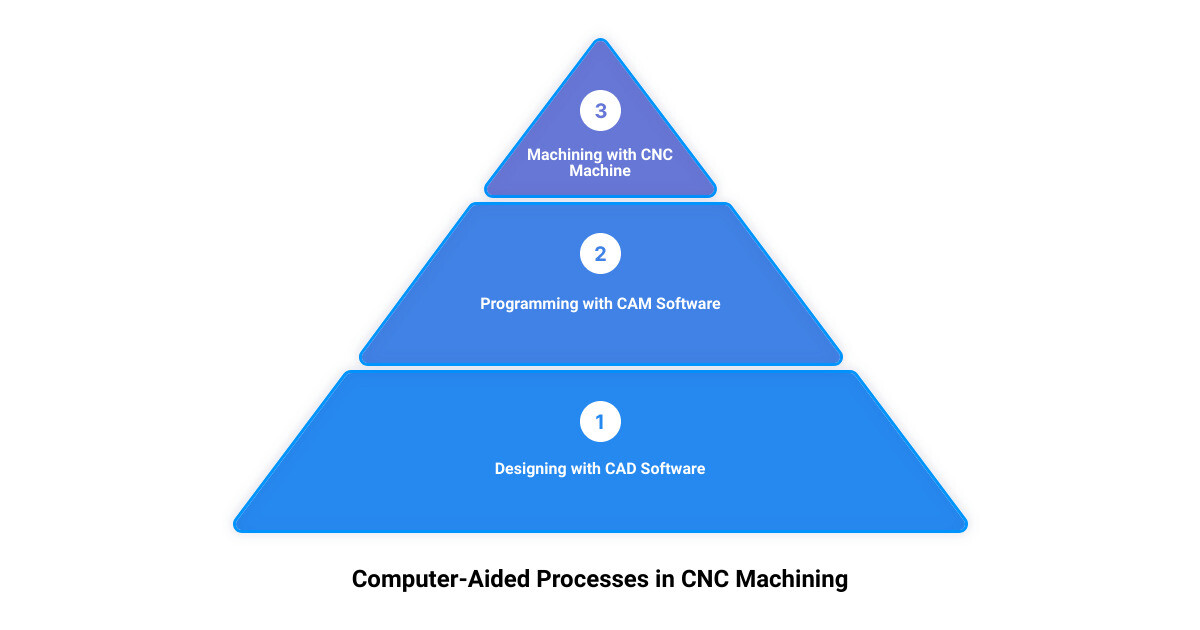

The Use of Computer-Aided Tools and Components in Aerospace CNC Machining

The world of aerospace CNC machining revolves around Computer Numerical Control (CNC), a technology that turns digital blueprints into physical parts with incredible accuracy. This process relies heavily on computer-aided design (CAD) and computer-aided manufacturing (CAM) tools. These software programs allow engineers to design complex parts and generate the precise instructions that CNC machines follow.

The digital nature of this process offers several key advantages. For one, it eliminates the risk of human error that can come with traditional manual machining. This leads to a significant reduction in part errors and defects, resulting in improved accuracy and consistency. Furthermore, the use of computer-aided tools in CNC machining allows for the creation of complex shapes and geometries that would be virtually impossible to achieve manually.

Major CNC Machine Operations: Precision CNC Milling and Precision CNC Turning

Aerospace CNC machining often involves two major operations: precision CNC milling and precision CNC turning.

Precision CNC milling is a multi-axis machining process that uses a milling machine to create parts. This machine moves along the X, Y, and Z linear axes and A and B rotational axes, making it possible to create intricate shapes and geometries. Specifically, 5-axis CNC milling machines are frequently used in the aerospace industry as they can work on up to five directions of the workpiece in a single operation. This not only reduces errors but also significantly cuts down on lead time.

On the other hand, precision CNC turning, also known as subtractive machining, involves removing material to generate the desired shape. This process is particularly useful for creating aerospace parts with cylindrical shapes like screws, nuts, threads, connector pins, fasteners, and shafts. Just like with CNC milling, the computer controls the speed and position of the tool and material used, ensuring a highly precise process.

Understanding these processes is crucial when navigating the world of aerospace CNC machining. By leveraging the power of computer-aided tools and mastering major operations like precision CNC milling and turning, manufacturers can create high-quality, reliable parts for the aerospace industry.

Materials and Surface Finishes in Aerospace CNC Machining

In the realm of aerospace CNC machining, the choice of materials and surface finishes plays a pivotal role in determining the functionality, durability, and longevity of the manufactured parts. This section delves into the commonly used materials and surface finishes in aerospace CNC machining, shedding light on their unique characteristics and their impact on the final product’s quality.

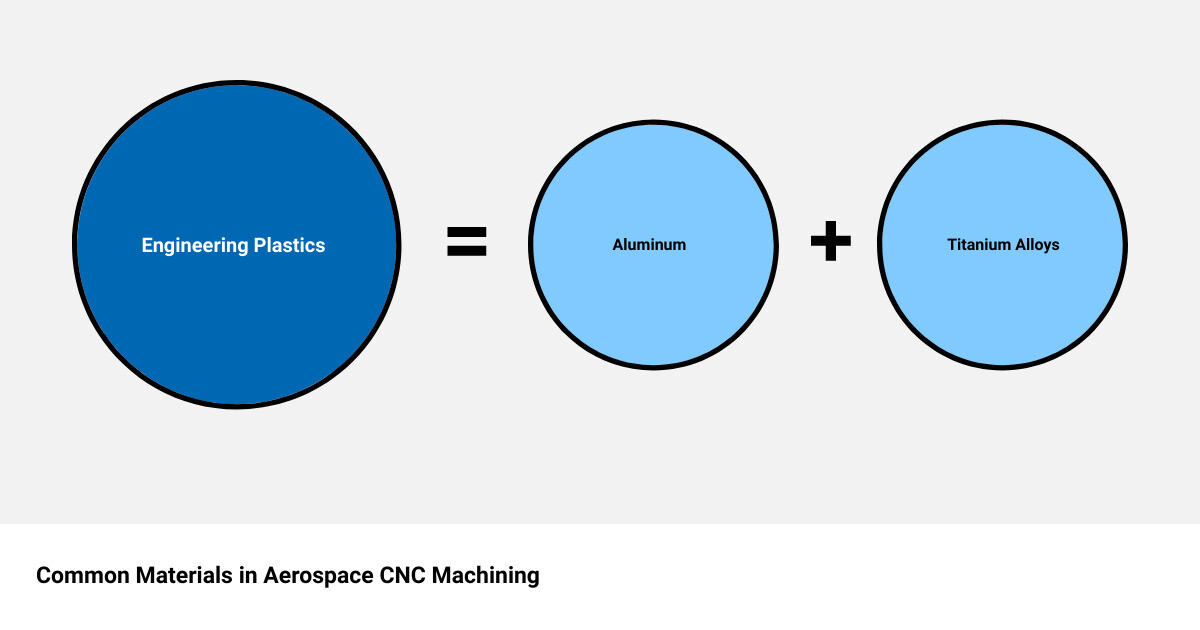

Commonly Used Materials: Aluminum, Titanium Alloys, and Engineering Plastics

The aerospace industry often resorts to specific materials for their unique properties that align with the stringent demands of aerospace applications. The most commonly used materials include aluminum, titanium alloys, and engineering plastics.

Aluminum and Aluminum Alloys are frequently used for their high tensile strength and lightweight, making them ideal for constructing aircraft parts. Popular alloys such as Aluminum 7075, which is rich in zinc, offer good fatigue strength and are used extensively for wings, fuselage, and support structure components.

Titanium and Titanium Alloys are another staple in the aerospace industry. Renowned for their excellent performance under high temperatures, corrosion resistance, and impressive strength-to-weight ratio, titanium alloys are used in commercial and military aircraft alike. Despite being harder to machine than aluminum, the benefits of titanium make it a preferred choice for parts such as discs, blades, shafts, and casings.

Engineering Plastics like PEEK, polycarbonate, and Ultem are also used in aerospace CNC machining. Their low weight, excellent impact and vibration resistance, sealing capabilities, and chemical resistance make them a valuable alternative to metals, especially for prototype CNC machining. These plastics are used for creating parts like cabin interiors, tray tables, wear pads, and valve components.

Surface Finishes for CNC Aircraft Parts: Anodizing, Passivation, Polishing, and Powder Coating

The selection of the right surface finish is crucial in aerospace CNC machining as it directly impacts the part’s performance, durability, and maintenance requirements. Notable surface finishes used in the industry include anodizing, passivation, polishing, and powder coating.

Anodizing involves immersing the part into an electrolyte solution to create a uniform oxide layer on the part’s surface, effectively protecting it from corrosion and wear. There are two popular types of anodizing used on aerospace parts: Type II for decorative purposes and Type III for a stronger, protective hard coat layer.

Passivation is a post-processing method that improves the surface quality and functionality of products by enhancing corrosion resistance and reducing surface impurities, thus reducing the need for maintenance.

Polishing is a straightforward procedure that uses abrasion to create a smooth, attractive finish. Apart from aesthetic enhancement, polishing can also increase a material’s durability by reducing the chances of chipping or cracking.

Powder Coating is a common surface finish for metallic aerospace parts due to its functional diversity and durability. This finish provides resistance to scratches and fading, while also offering a wide range of color options for improved aesthetics.

By understanding these materials and surface finishes, manufacturers can make informed decisions to ensure the production of high-quality, accurate, and durable aerospace parts. And with companies like TMC Technologies providing top-tier CNC lathe parts, the future of precision aerospace CNC machining is indeed promising.

Applications and Benefits of Aerospace CNC Machining

As we navigate through the intricate world of aerospace CNC machining, it becomes clear that it’s not just about the process, but also about the end products it yields.

Applications: Electrical Connectors, Valve Components, Oxygen Generation Components, Shafts, and More

From the tiny valves to the all-important electrical connectors, CNC machining aids the production of numerous components that are integral to the aerospace sector. Electrical connectors, for instance, are a critical part of the aircraft’s electrical system. Given the weight and space constraints, the production of these components often relies on CNC machining.

Valve components may be small, but they have widespread applications in the aerospace sector. CNC-machined valves ensure part accuracy and efficient, secure operations, while oxygen generation components produced through CNC machining are strong, temperature-resistant, and lightweight, contributing to the safety systems of aircraft.

Then, we have shafts, which play a key role in power transmission in aeronautical applications. CNC machining allows the production of strong items made of heat-resistant materials. Other applications of aerospace CNC machining include the production of cabin parts, wing ribs, fuselage components, actuators, motion controls, engine housings, landing gear components, discs, and filter bodies.

Benefits: Lightweight Components, Minimal Part Errors, High Accuracy, and Efficiency

Beyond the vast applications, aerospace CNC machining brings several benefits to the table. One of the most notable benefits is the ability to create lightweight components. With weight being a vital factor in aerospace technology, CNC machining can produce robust yet lightweight materials, ensuring the aircraft or spacecraft can maintain optimal performance without unnecessary weight burden.

The precision inherent in CNC machining also results in minimal part errors. Traditional manufacturing methods may be prone to failure due to human-induced dimensional errors. However, with CNC machining, aerospace parts adhere to strict size, tolerance, and performance standards, ensuring high performance and preventing part failure.

Moreover, CNC machining guarantees high accuracy and consistency. With accuracy to a few micrometers and a minuscule margin for error, CNC machines produce parts that fit accurately into aircraft, preventing general part failure and consequential loss of property.

Lastly, CNC machining enhances efficiency in the aerospace industry. Being an automated process, it increases production speed, reduces time, and ensures the production of accurate and consistent parts. This not only minimizes waste but also reduces the need for rework due to dimensional inaccuracies.

In a nutshell, aerospace CNC machining offers a blend of wide-ranging applications and benefits that make it a game-changer in the aerospace industry. Whether it’s about creating lightweight components or ensuring high accuracy, CNC machining is indeed precision at its finest.

The Impact of CNC Machining on the Aerospace Industry

As the curtain lifts on the new normal of a post-COVID world, the aerospace industry is readying for a sharp ascent. At the heart of this recovery and advancement lies the precision and efficiency of CNC machining.

The Role of CNC Machining in the Economic Recovery of the Aerospace Industry Post-COVID-19

The pandemic dealt a devastating blow to the aerospace industry, grounding flights and stalling production. However, the industry is now poised for a robust recovery, and CNC machining plays a pivotal role in this resurgence. While commercial aerospace is still struggling due to the reduced travel demand, the defense sector remains strong, driven by consistent government budgets.

The need of the hour for aerospace manufacturers is to ramp up production swiftly, eliminate errors, and offer top-quality parts to make up for the lost time and to meet the emerging market demands. Enter CNC machining. With its ability to manufacture parts at high speed and precision, CNC machining is essentially the secret weapon for the aerospace industry’s recovery. It allows manufacturers to meet tight schedules and high quality standards, hence contributing significantly to the sector’s economic rebound.

The Shift Towards Lightweight and Heat-Resistant Materials in Aerospace Manufacturing

Beyond its role in the industry’s economic recovery, CNC machining is also at the forefront of a major shift in aerospace manufacturing: the move towards lightweight and heat-resistant materials. While aluminum was once the mainstay, the focus has now shifted towards more heat-resistant alloys and non-metal composites.

Materials like nickel and titanium, known for their high-temperature resistance, have become increasingly popular. Non-metal composites like ceramics are also gaining traction due to their light weight and high stress endurance. These materials are crucial for parts that experience extreme temperatures and high stresses during flight, such as engine components.

However, these materials pose new challenges—they are harder to machine than aluminum. But thanks to advanced CNC machining and computer-aided manufacturing (CAM) software, these challenges can be overcome, ensuring safe and efficient machining.

In conclusion, the impact of CNC machining on the aerospace industry is transformative, driving both its post-pandemic recovery and the shift towards advanced materials. This highlights the central role of CNC machining in the future trajectory of the aerospace industry, ensuring precision, efficiency, and innovation at every turn.

TMC Technologies: A Leader in Aerospace CNC Machining

In the realm of precision, efficiency, and innovation, one name stands out—TMC Technologies. With over three decades of experience and a deep understanding of the aerospace industry’s strict protocols and regulations, TMC Technologies has emerged as a leader in aerospace CNC machining.

TMC Technologies’ Unique Selling Proposition: High-Quality CNC Components and Additional Machining Services

The unique selling proposition of TMC Technologies lies not only in their ability to manufacture high-quality CNC components but also in their comprehensive suite of additional machining services. Besides precision CNC machining, they offer grinding, heat treating, light fabrication/assembly, and various other secondary operations.

TMC Technologies leverages state-of-the-art automated tools and technology, allowing them to manufacture a variety of materials efficiently and cost-effectively. These include but are not limited to aluminum alloys, brass, titanium, stainless steel, and plastics. This versatility enables them to cater to a wide array of aerospace applications, making them a one-stop shop for all CNC machining needs.

Moreover, the team at TMC Technologies understands the urgency often associated with the need for precision parts in the aerospace industry. They strive to deliver short lead times without compromising the high-quality workmanship they are known for. This balance of speed and quality is a testament to their expertise and commitment to customer service.

The Use of 5-Axis CNC Machining at TMC Technologies for Complex Aerospace Components

To tackle the challenges of creating complex aerospace parts such as landing gear, electrical components, and transmissions, TMC Technologies leverages the power of 5-axis CNC machining. This advanced machining process allows them to work on up to five directions of the workpiece in a single operation. This not only reduces errors and lead time but also ensures part accuracy and precision.

The use of 5-axis CNC machining demonstrates TMC Technologies’ commitment to staying at the forefront of technology. It allows them to produce intricate shapes and geometries with high precision, ensuring that the produced parts fit accurately and perform reliably in the demanding environment of aerospace applications.

In conclusion, TMC Technologies has carved a niche for itself in the realm of precision aerospace machining. Their combination of extensive industry experience, cutting-edge technology, rigorous quality control, and a commitment to customer satisfaction makes them a trusted partner in the aerospace CNC machining industry. Their work is a testament to the transformative impact of CNC machining on the aerospace industry, embodying precision, efficiency, and innovation at every turn.

Conclusion: The Future of Aerospace CNC Machining

As we trace the contours of the horizon, it’s clear that the future of aerospace CNC machining is not only bright but teeming with untapped potential. The combination of advanced automation, utilization of precision materials, and the increasing importance of skilled professionals is shaping an exciting trajectory for this sector.

The Role of Automation and CNC Machining Centers

The aerospace industry has always been at the forefront of technological innovation, and their adoption of advanced CNC machining centers is no exception. With the integration of sophisticated technologies like multi-axis machines and automated cells composed of robotics, measurement, and vision systems, the industry is poised for a new wave of efficiency and precision. This shift towards automation isn’t just a futuristic concept; it’s a reality that’s already transforming the way aerospace components are manufactured, ensuring they meet exact specifications and the highest international quality standards.

The Rise of Lightweight and Heat-Resistant Materials

The future is also witnessing a shift towards lightweight and heat-resistant materials in aerospace manufacturing. While aluminum once dominated the industry, more composites and alloys are now taking its place. Heat-resistant alloys, often nickel and titanium, and nonmetal composites like ceramics are becoming more common. These materials are more difficult to machine than aluminum, but with advanced CAM software and precision CNC machining, the aerospace industry is meeting this challenge head-on.

The Vital Role of Skilled Professionals

While we marvel at the wonders of technology, we cannot overlook the crucial role of skilled professionals in the future of aerospace CNC machining. These aren’t just operators; they are problem solvers and innovators. They navigate the complexity of modern machining tools, automation, and strict regulatory guidelines, ensuring high-quality CNC machined parts. Companies like TMC Technologies, with their team of dedicated professionals, are at the forefront of harnessing the power of skilled personnel in the industry.

TMC Technologies: A Leader in Aerospace CNC Machining

As we look to the future, the blend of automation and skilled professionals, coupled with the rise in the use of advanced materials, will continue to drive aerospace CNC machining to new heights. TMC Technologies is leading this charge, delivering high-quality CNC components and additional machining services. Their use of 5-axis CNC machining for complex aerospace components exemplifies the fusion of advanced technology and skilled craftsmanship that is propelling the industry forward.

In conclusion, the future of aerospace CNC machining is a bright one, marked by continuous innovation, precision, and efficiency. It’s a future where the industry’s commitment to safety and quality is matched only by its relentless pursuit of technological advancement. And in this future, companies like TMC Technologies are setting the pace, proving that when it comes to aerospace CNC machining, precision, indeed, is at its finest.