Deep in the heart of our world’s ever-evolving industries is a cornerstone of intricate technological prowess—aerospace machined parts. They are the unsung heroes that sit at the core of some of the most technologically advanced machinery man has ever achieved—the majestic aircrafts and spacecrafts that grace our skies and venture beyond earthly bounds. For manufacturing companies on the hunt for components that mirror their need for top-tier quality and precision, the journey often leads to exploring the intricate world of aerospace CNC machining.

This world of precision and intricacy introduces us to three primary players— the aerospace machinists, the CNC machining process, and of course, the aerospace components themselves. Each one plays an essential role in the grand scheme of aerospace industry. Our expert at TMC Technologies can testify to the countless hours and meticulous attention to detail invested into the crafting of each part. Not to mention, the highly-valued additional machining services for custom applications that bring the unique visions of our clients to life.

Venturing into this complex ecosystem, it becomes abundantly clear that accuracy, consistency and reliability are the commanding forces behind manufacturing process. It is not enough to just churn out components; it is a matter of crafting parts that uphold the rigorous standards of the aerospace industry and stand up to the test of constant use and time.

To give a panoramic view of what we mean when we dwell into aerospace machining parts, we’ve summarized the basics:

- Aerospace machinists use computer and mechanically controlled machines to create specialized aircraft parts.

- Aerospace CNC machining is a process that employs computer numerical control to create precision components.

- Aerospace components generally refer to products like airframes, fasteners, hardware and various system components.

It is our mission here at TMC Technologies to not just contribute to this industry, but to define it. From offering high-quality CNC machined parts to providing around-the-clock customer service, we embody the core principles of this industry with our commitment to providing the best for our clients. In this article, we pull back the curtain on the world of aerospace machined parts, diving deep into the intricacies of this industry through the lens of our long-standing experience in the field.

Stay tuned as we delve deeper into the fascinating universe of aerospace machining parts, from the rigorous process of their creation to their significant role in powering industries worldwide.

The Role of Aerospace Machinists

Aerospace machinists are the unsung heroes of the aerospace industry. They are key players in shaping the future of space travel and aviation. Their role extends from crafting detailed aircraft and spacecraft parts to using advanced computer-controlled machines, all while specializing in specific types of aircraft.

Creating Detailed Aircraft and Spacecraft Parts

The complexity of their job cannot be overstated. Aerospace machinists are responsible for creating a myriad of intricate components that find their place in different types of aircraft, from commercial planes to spacecraft. These parts not only need to be precise down to the smallest detail, but they also need to be robust enough to withstand the demanding environment of space or high-altitude flight.

At TMC Technologies, we understand the level of precision required in this process. We apply our wealth of experience and industry-leading technology to manufacture high-quality aerospace machined parts that meet the stringent specifications of the aerospace industry.

Use of Computer and Mechanically Controlled Machines

As the industry advances, so does the technology employed by aerospace machinists. Today, they utilize a range of computer and mechanically controlled machines, such as lathes and grinders, to create these parts.

At the heart of this process is the use of Computer Numerical Control (CNC) machines. CNC machining is a computerized manufacturing process that moves cutting tools using pre-programmed code and software to create parts with a level of precision and consistency that would be virtually impossible using manual methods.

Specialization in Specific Types of Aircraft

Machining parts for different types of aircraft requires a keen understanding of their unique demands. For example, parts for rotary-wing airplanes, like helicopters, may have different requirements compared to those for fixed-wing aircraft or spacecraft.

At TMC Technologies, we leverage our extensive experience across various aircraft types to meet these diverse needs. Whether you require components for a commercial jet or a cutting-edge spacecraft, our team of skilled aerospace machinists can deliver parts of the highest quality, tailored to your specific requirements.

In conclusion, the role of aerospace machinists is pivotal in the aerospace industry. Their expertise in creating detailed parts and use of advanced machines enables the creation of components that are essential for safe and efficient air and space travel. As we continue to push the boundaries of aerospace technology, their role will only become more vital.

In the next section, we will delve further into the fascinating process of Aerospace CNC Machining, shedding light on how it contributes to the precision and efficiency of manufacturing these intricate parts. Stay tuned.

Understanding Aerospace CNC Machining

Stepping into the realm of aerospace manufacturing reveals a world of precision, complexity, and futuristic technology. At the heart of this lies Computer Numerical Control (CNC) – an advanced system that has revolutionized the manufacturing process.

The Process of Using Computer Numerical Control

CNC is a computerized system that automates the manufacturing process, primarily by controlling the movement of tools and machinery. This technology follows instructions from intricate software to shape raw materials into components with exact dimensions. In essence, this is what we at TMC Technologies refer to when we talk about precision aerospace machining.

Benefits of CNC Machining in Aerospace

There are numerous benefits to using CNC machining in the aerospace industry, some of which include:

-

Greater precision and accuracy: CNC machining allows for high accuracy, repeatability, and quality control in creating parts. This technology minimizes waste by reducing scrap from incorrect dimensions or damaged surfaces caused by manual machining, ensuring efficient use of resources.

-

Increased production speed: With CNC machining, production speed is significantly increased, reducing time and boosting manufacturing efficiency. This automated process ensures that produced parts are accurate and consistent, leading to minimal waste.

-

Cost savings: The automation of CNC machining eliminates the need for manual labor, leading to considerable cost savings. This is particularly beneficial in an industry like aerospace, where precision is paramount, and any errors can lead to high costs.

The Importance of Precision and Consistency

In the aerospace industry, the demand for parts with extreme precision is high, given that most parts have complex designs and geometries. To meet this demand, aerospace precision machining is employed, using various CNC machine types to achieve high precision.

For instance, precision CNC milling, a multi-axis machining process, allows for the creation of intricate shapes and geometries. On the other hand, precision CNC turning, also known as subtractive machining, involves removing material to generate the desired shape – a process that is highly precise as the computer controls the speed and position of the tool and material used.

The importance of precision and consistency in aerospace CNC machining cannot be overstated. The stakes are high, as any errors or inconsistencies can lead to part failure, loss of property, and in worst-case scenarios, loss of life.

In our commitment to meeting these exacting standards at TMC Technologies, we ensure that our CNC machining processes adhere strictly to size, tolerance, and performance standards, delivering high-quality components that meet the demanding requirements of the aerospace industry.

Common Aerospace Components and Their Machining

In the vast and intricate world of aerospace engineering, various components come together to create the final product. Each piece is essential to the overall function and safety of the aircraft. Here, we will take a closer look at some of the most common components that we manufacture at TMC Technologies, and the critical role CNC machining plays in their production.

Airframes, Fasteners, and Hardware

The airframe is the mechanical structure of an aircraft, including the fuselage, wings, and undercarriage. It is responsible for withstanding all flight loads and is typically constructed from high-strength aluminum alloys. At TMC Technologies, we use advanced CNC machines to produce these complex airframe structures with high precision and consistency, ensuring they withstand the highest loads and stresses during flight operations.

Fasteners and hardware, though small in size, have a colossal impact on an aircraft’s safety and performance. From screws and nuts to rivets and bolts, these components are critical in securing various parts of the aircraft together. Our precision CNC machining services ensure that these hardware pieces are produced to exact specifications, contributing to the overall performance and longevity of the aircraft.

System Components and Their Importance

System components encompass a wide range of parts, from communication and navigation systems to fuel and hydraulic systems. These components are integral to the aircraft’s operation, and each one requires the utmost precision and accuracy in manufacturing. For instance, intricate parts for navigation and communication systems demand the highest level of accuracy and consistency.

At TMC Technologies, we understand the importance of precision in these critical components. Our state-of-the-art CNC machining services ensure each part is manufactured to exact specifications, adhering to the stringent quality and safety standards required in the aerospace industry.

The Role of CNC Machining in Manufacturing These Components

CNC machining plays a pivotal role in the aerospace industry. Its ability to consistently produce complex parts to precise specifications makes it an invaluable tool for manufacturing various aerospace components. From airframes and fasteners to intricate system components, our CNC machines at TMC Technologies deliver high-quality, reliable aerospace parts.

Through the use of computer-aided tools and components, we can produce and maintain aircraft and space parts with high accuracy and precision. Our advanced CNC machines move cutting tools using pre-programmed code and software, eliminating potential human error and increasing efficiency. This level of precision is paramount in the aerospace industry, where the slightest inaccuracy can lead to catastrophic results.

In conclusion, the manufacture of aerospace components involves a combination of precise materials, advanced CNC machining, and strict quality assurance. At TMC Technologies, we are dedicated to providing precision CNC machined parts that meet these stringent requirements, ensuring the safety and performance of your aircraft.

Materials Used in Aerospace Machining

In the world of aerospace manufacturing, the selection of materials is a critical aspect that determines the workability, longevity, and performance of the final product. At TMC Technologies, we understand how important it is to work with materials that can withstand the tough demands of aerospace applications. As such, we work with a variety of materials, each bringing their unique properties and machining requirements.

Aluminum and Aluminum Alloys

Aluminum, known for its lightweight yet strong nature, is one of the most widely used metals for machining aerospace parts. Its high tensile strength and lightweight properties make it ideal for various aerospace applications. Aluminum is also very formable, which simplifies machining for CNC machines.

Among the aluminum alloys, aluminum 7075, whose primary alloying component is zinc, is notably popular in the aerospace industry. This alloy is notable for its good fatigue strength and has been used extensively to produce wings, fuselage, and support structure components.

We also work with other machinable aircraft aluminum alloys like 4047 (cladding/filler), 6951 (fins), and 6063 (structural). Alloys of the 6000-series, in particular, are considered easier to machine than others, making them a preferred choice for aerospace components.

Titanium and Titanium Alloys

Titanium, another crucial material used in aerospace machining, is renowned for its high strength-to-weight ratio and corrosion resistance. It works well at high temperatures, which makes it an indispensable material in aerospace manufacturing.

Commercial and military aircraft like the Airbus A380 and Boeing B787, as well as helicopters like the F-22, F/A-18, and UH-60 Black Hawk, all require significant amounts of titanium for various parts. Components for airframes and jet engines made of titanium include discs, blades, shafts, and casings.

However, it’s worth noting that titanium can be more challenging to machine due to its hardness, leading to tool wear and heat buildup, which could distort the material. This necessitates running titanium aerospace machining at a lower machine RPM and with a higher chip load.

Engineering Plastics

Engineering plastics also play a crucial role in aerospace machining, thanks to their incredibly low weight, excellent impact and vibration resistance, sealing capabilities, and chemical resistance. Compared to metals, they provide better electrical insulation and are ideal for prototyping.

PEEK, polycarbonate, and Ultem are high-performance polymers used in aerospace machining. These plastics can be CNC-machined to create aircraft parts like cabin interiors, tray tables, wear pads, armrests, back-lit instrument panels, valve components, housings, tubing, and insulation.

At TMC Technologies, we understand the unique machining requirements of these materials and use our expertise to deliver high-quality, accurate, and durable components. Our commitment to quality and precision ensures that the aerospace machined parts we produce meet and exceed the stringent standards of the industry.

The Benefits of CNC Machining for Aerospace Parts

As industry leaders in aerospace CNC machining, we at TMC Technologies have seen firsthand the myriad benefits this advanced manufacturing method brings to the table. Not only does CNC machining allow us to create complex parts with incredible accuracy and precision, but it also offers unparalleled consistency and efficiency.

Creating Lightweight Components

Weight plays a pivotal role in the world of aviation and space travel. Every gram can have a significant impact on fuel consumption, cargo capacity, and overall performance. That’s where CNC machining shines. It allows us to fabricate robust yet lightweight parts by using advanced materials and creating thin-walled structures. This is one of the most critical factors that make CNC machining perfect for the aerospace industry.

Minimal Part Errors

Traditional manufacturing methods often introduce dimensional errors due to the human element involved, leading to part failure. However, with precision CNC machining, this risk is considerably reduced. Our state-of-the-art CNC machines ensure that aerospace parts comply with strict size, tolerance, and performance standards, ensuring high performance while preventing part failure.

High Accuracy and Precision

The margin for error in the aerospace industry is minuscule, and precision is paramount. Our CNC machines are accurate to a few micrometers, ensuring that parts fit accurately and prevent general part failure and consequent loss of property. The high level of precision and accuracy achieved through CNC machining not only enhances safety but also improves the performance of the aircraft.

Consistency and Efficiency

CNC machining significantly boosts manufacturing efficiency in the aerospace industry. Our automated process increases production speed and reduces time, ensuring that the parts we produce are consistent and accurate. This high level of consistency means that there is minimal waste, and parts seldom need to be reworked due to dimensional inaccuracies.

The use of CNC machining in the creation of aerospace parts is a testament to the industry’s commitment to safety, efficiency, and innovation. From creating lightweight components to ensuring minimal part errors, high precision, and consistency, the benefits of CNC machining are undeniable. At TMC Technologies, we’re proud to be at the forefront of this technology, delivering the highest quality parts to meet the exacting demands of the aerospace industry.

Precision CNC Milling and Turning in the Aerospace Industry

In the world of aerospace manufacturing, where precision, consistency, and efficiency are the name of the game, precision CNC milling and turning play pivotal roles. These processes allow us at TMC Technologies to produce complex, high-precision parts, adhering to strict quality standards.

The Role of Precision CNC Milling

Precision CNC milling, a cornerstone of our operations, is a cutting process that uses rotary cutters to remove material from a workpiece. This process is guided by a computer program, ensuring that each part is machined to exact specifications. With the use of advanced CAD and CAM software, CNC milling allows us to craft intricate geometries and components that are integral for the functionality, safety, and reliability of aerospace applications.

At TMC Technologies, our advanced multi-axis CNC machines not only offer functionality but also the capability to machine aerospace parts with innovative design trends. These machines can perform simultaneous translation and rotational movements, allowing for precise machining of intricate parts and complex tool designs.

The Role of Precision CNC Turning

Precision CNC turning is another vital process in the production of aerospace machined parts. Turning involves rotating the workpiece while a single-point cutting tool is moved parallel to the axis of rotation. This process is commonly used for creating cylindrical parts such as screws, nuts, and shafts that are essential components in aerospace applications.

Our CNC turning systems at TMC Technologies are designed to meet the exacting demands of the aerospace industry. We can create components that adhere to tight tolerances, achieving precision as small as 4μm. This high level of accuracy is critical in an industry where even the smallest error can have significant consequences.

The Importance of Surface Finishes

Beyond the machining process, surface finishes play a crucial role in the performance and longevity of aerospace components. Different surface finishes provide varying levels of protection against wear, corrosion, and other environmental factors that could potentially harm the parts.

The aerospace industry commonly employs four types of surface finishes for CNC machined parts: anodizing, passivation, polishing, and powder coating. Each of these treatments has its unique benefits. For instance, anodizing forms a protective oxide layer on the part’s surface, improving its resistance to corrosion. Polishing, on the other hand, enhances the material’s durability by reducing the chance of chipping or cracking.

At TMC Technologies, we recognize the importance of surface finish in the overall quality and performance of aerospace machined parts. We ensure that our CNC machining processes are complemented with the appropriate surface treatments to meet the rigorous standards of the aerospace industry.

In the high-stakes game of aerospace manufacturing, precision CNC milling and turning, coupled with the right surface finish, are keys to unlocking success. These processes allow us to create high-quality, reliable, and durable components that meet the stringent demands of the aerospace industry.

Tips for Machining Aerospace Parts

Demystifying the complex process of aerospace manufacturing isn’t an easy task. However, with the right approach and adherence to certain best practices, the production of aerospace machined parts becomes less daunting and more efficient. Here, we’ll explore some tried-and-tested strategies that can enhance the production process, leading to superior quality products.

Running a Simulation

The first step to flawless machining is to test out your designs and processes in a simulated environment. Before diving into actual part production, it’s advisable to leverage CNC machining simulation software. This software allows you to visualize your aerospace parts, ensuring that you get everything right from the get-go. It’s like rehearsing a play before the actual performance. This way, it’s easier to identify and rectify potential issues before they become costly production mistakes.

Using the Right Machine and Cutting Tools

Different aerospace parts require different machines and cutting tools. Not all CNC machines and tools are suitable for creating every type of aerospace component. For instance, a job may require a large, high-speed mill specifically designed for such a task. It’s crucial to match the right tools and machines to specific jobs to boost efficiency and accuracy. As the saying goes, using the right tool for the right job is half the battle.

Breaking Up Production into Specialized Parts

The production of aerospace parts can be overwhelming when viewed as a single, monolithic task. To make it manageable, break up the production process into specialized parts. This approach allows you to focus on each component’s unique requirements and characteristics, simplifying the overall production process. Think of it as assembling a jigsaw puzzle—each piece has its place, and focusing on one piece at a time makes the task less daunting and more manageable.

Committing to Proper Design

The design phase is arguably one of the most critical steps in product development. A well-thought-out design not only ensures the part’s function and fit but also significantly impacts the machining process. A poorly designed part can lead to increased machining time, higher production costs, and potential quality issues. Therefore, it’s essential to commit to proper design practices right from the start.

Remember, these tips are not a one-size-fits-all solution. Every aerospace part is unique, and its production may require different strategies and approaches. At TMC Technologies, we pride ourselves on our ability to adapt and tailor our processes to meet the specific needs of each project. Our commitment to excellence and precision ensures that we deliver high-quality aerospace machined parts that meet or exceed industry standards.

Applications of Aerospace CNC Machining

CNC machining isn’t just about creating aircraft or spacecraft. It’s a technology that’s critical to the production of a wide range of aerospace components, each serving a specific purpose in the overall system. Let’s take a closer look at some of these vital elements.

Electrical Connectors

Ease up on the throttle and let’s zoom into the world of electrical connectors. These are crucial components of an aircraft’s electrical system. Given the limited space on board, these parts need to be compact yet highly efficient, and that’s where CNC machining comes in. We at TMC Technologies leverage our expertise to produce these components, ensuring they meet the weight and space constraints of the aircraft.

Valve Components

Valve components may be small in size, but their role in aerospace applications is immense. They regulate and control the flow of fluids within an aircraft, ensuring safe and secure operations. The precision and accuracy offered by CNC machining make it the ideal process for producing these components. At TMC Technologies, we understand the importance of these tiny parts and are committed to delivering CNC-machined valves that meet stringent aerospace standards.

Oxygen Generation Components

In the aerospace industry, safety is paramount. To ensure a safe environment for passengers and crew, aircraft are equipped with oxygen-generating systems. These systems need to be lightweight, temperature-resistant, and robust. We utilize CNC machining to produce these components, guaranteeing that they meet all these criteria.

Shafts

Shafts are the unsung heroes of aeronautical applications. They play a critical role in power transmission, enabling the aircraft to function efficiently. To produce these vital components, we at TMC Technologies use CNC machining. This process allows us to create strong, heat-resistant shafts, ensuring the reliable and smooth operation of the aircraft.

In addition to these, aerospace CNC machining also finds applications in the production of various other components, including cabin parts, wing ribs, fuselage components, actuators, motion controls, engine housings, landing gear components, discs, and filter bodies. Each of these parts plays a specific role in the function and safety of an aircraft or spacecraft, and at TMC Technologies, we are committed to delivering high-quality, precision machined components for every purpose.

TMC Technologies: A Leader in Aerospace CNC Machining

As the aerospace industry continues to evolve, so does the demand for high-quality, precision-machined parts. At TMC Technologies, we have honed our skills and broadened our capabilities to meet and surpass these demands, positioning ourselves as a trusted leader in aerospace CNC machining.

High-Quality CNC Lathe Parts

At the core of our services is our commitment to providing high-quality CNC lathe parts. With over three decades of experience under our belt, we have the expertise to handle the intricate demands of aerospace applications. Our team of highly trained engineers and technicians use state-of-the-art machining technologies like 3D modeling and CNC turning to ensure accuracy and superior workmanship.

Our reputation extends beyond just providing parts. We are also known for the consistent delivery of high-quality services, which has allowed us to carve out a niche in the competitive landscape of aerospace components manufacturing.

Additional Machining Services

Beyond manufacturing, we offer a wide range of additional machining services. These include grinding, heat treating, light fabrication/assembly, and other secondary operations. Our comprehensive approach ensures that your aerospace parts are not only manufactured to the highest standards but also finished and assembled with the utmost precision.

Our CNC milling, drilling, grinding, and fabrication services cater to a variety of aerospace applications. We also offer rapid prototyping services to help you test out your ideas before committing to production runs, ensuring cost-effectiveness and minimizing risks.

Tool Design and Fabrication for Custom Applications

At TMC Technologies, we understand that every aerospace application is unique. As such, we offer custom tool design and fabrication services to meet your specific needs. Whether you need a specialized tool for a complex part or a custom fixture for an unconventional assembly, we have the expertise and the resources to deliver.

Our team works closely with your engineers to understand your specific requirements and design the perfect tool for the job. This collaborative approach ensures that the final product is not only functional but also optimizes your production process for efficiency and cost-effectiveness.

In conclusion, when it comes to aerospace CNC machining, TMC Technologies is a name you can trust. Our blend of extensive industry experience, advanced technology, rigorous quality control, and commitment to customer satisfaction positions us as your ideal partner in the world of precision aerospace machining. Contact us today to learn more about our services and how we can help you achieve your production goals.

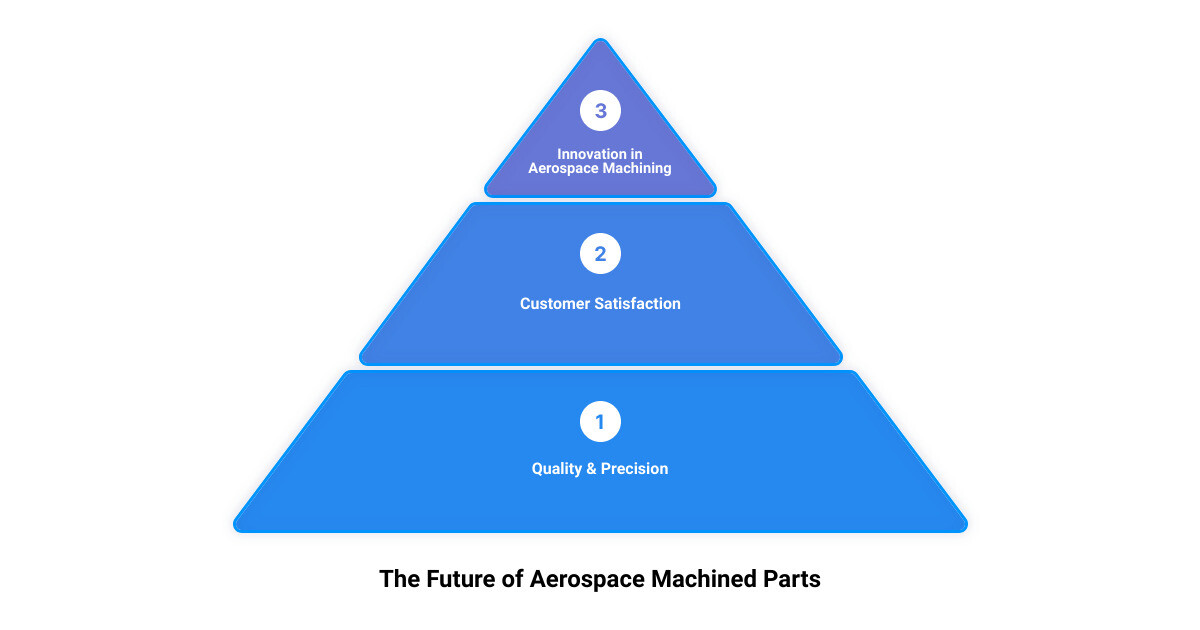

Conclusion: The Future of Aerospace Machined Parts

A new chapter is dawning in the world of aerospace machined parts. Impeccable precision, cutting-edge technology, and industry innovation are driving this transformation. As we navigate this exciting age of aerospace engineering, we at TMC Technologies are committed to leading the charge.

Automation and skilled professionals are two pivotal factors shaping the future of precision aerospace machining. The aerospace industry has always been a pioneer in adopting innovative technologies, and the increasing use of automation is a testament to this. Automated machining processes offer unmatched precision, speed, and reliability – all of which are critical in the aerospace industry.

From automated cells composed of robotics to integrated error-proofing techniques, the landscape of aerospace manufacturing is becoming more efficient and accurate. Yet, it is important to remember that behind this technological advancement, our skilled professionals remain at the heart of the industry. As problem solvers and innovators, they navigate the complexity of modern machining tools, automation, and strict regulatory guidelines.

Our team at TMC Technologies is dedicated to producing high-quality CNC machined parts with quick turnaround times. Our machinists are not just operators; they are innovators who use advanced productivity tools to augment the value of the most skilled manufacturing professionals.

Manufacturing components for the aerospace industry is a highly specialized field that requires precision, consistency, and a deep understanding of the unique challenges associated with aircraft and spacecraft parts production. We bring decades of experience and cutting-edge technology to the table, ensuring that each part we produce meets the highest standards of quality and precision.

The future of aerospace machined parts looks promising, with companies like TMC Technologies leading the charge. Our commitment to quality, precision, and customer satisfaction makes us a trusted partner for your aerospace machining needs.

In the end, the exciting advancements in aerospace machining are only as good as the expertise and quality control of those who harness them. At TMC Technologies, we live by this principle, ensuring that every aerospace part we manufacture is a testament to our dedication to excellence.

As we look to the future, we’re excited to continue pushing the boundaries of what’s possible in aerospace machining. Through our commitment to innovation, precision, and quality, we’re helping to shape the future of the aerospace industry, one machined part at a time.

This infographic shows the future trends in aerospace machined parts, highlighting the increasing role of automation, the importance of skilled professionals, and the commitment to precision and quality in aerospace machining.

Thank you for embarking on this journey with us. We hope to partner with you on your next project, leveraging our expertise to unlock the full potential of precision aerospace machining. Contact us today to learn more about how we can help you achieve your production goals.