In the world of manufacturing and precision machinery, the role of Vertical Turning Centers is rapidly growing. As manufacturers continuously seek to improve the accuracy, longevity, and cost-effectiveness of their machinery, the transition towards utilizing innovative equipment such as Vertical Turning Centers is becoming increasingly apparent.

Across numerous industries, efficient workshops and production centers have come to regard the Vertical Turning Center as a cornerstone of modern manufacturing. This machine’s vertically oriented spindle and its ability to perform 2.5 to 3-axis machining operations contribute significantly to its ovation.

Key factors such as precision, versatility, and innovation have significantly anchored the importance of the Vertical Turning Center to industries ranging from automotive, aerospace, to medical and industrial manufacturing. Most importantly, it’s the Vertical Turning Center’s cost-efficiency with little to no compromise on performance, that sets it apart from its counterparts.

As a company on the forefront of manufacturing innovation, TMC Technologies is deeply invested in harnessing the power of Vertical Turning Centers. Our manufacturing experts frequently adopt this game-changing equipment to optimize production processes, reduce error margins, and ensure high-quality output consistently.

Here’s a brief snippet of what you can expect from a Vertical Turning Center:

- Vertical Spindle Orientation: Its top-down approach allows for accurate and efficient cutting of workpieces.

- Broad Operational Capabilities: The machine can perform multiple functions like turning, milling, boring, tapping and more.

- Adaptable to Material Variety: Works efficiently with various materials like aluminum, stainless steel, brass, and titanium.

- Advanced Technologies: High-speed spindles and CNC capabilities aid in high-quality results.

- Cost-Efficiency: Typically lower priced than horizontal machining centers with similar functionality.

Stay tuned to learn more about the intricacies of these machines, the profound impact they have on various industries, and how TMC Technologies’ is leveraging the potentials of the Vertical Turning Center to stay at the forefront of manufacturing innovation.

Today, we’ll be diving deep into Vertical Turning Centers, exploring their structure and functions, key benefits, and how they make a difference in the manufacturing landscape.

What is a Vertical Turning Center?

A Vertical Turning Center is a specialized type of machine tool that stands out for its vertical orientation. This unique design, a hybrid between a traditional turning center and a vertical lathe, is specifically developed for handling shorter components that do not require a sub-spindle, tailstock, or bottom turret. The vertical construction of these machines gives them a smaller footprint compared to horizontal lathes, making them a practical choice for various machining operations.

The Difference Between Horizontal and Vertical Turning Centers

The fundamental difference between horizontal and vertical turning centers lies in the orientation of the spindle and how they interact with the workpiece. In a horizontal turning center, the spindle is horizontally oriented, and this setup is often used to mill grooves, slots, and shape flat surfaces.

In the case of vertical turning centers, the spindle axis is vertically oriented, and the milling cutters are held in the spindle as it rotates on its axis. This vertical orientation allows for more efficient chip evacuation and can accommodate larger, heavier workpieces.

The Difference Between a Lathe and a Turning Center

While the terms lathe and turning center are often used interchangeably, they refer to slightly different machines. A lathe, in its most traditional sense, performs a single operation – turning.

However, a turning center is a step up from a lathe. They are more advanced and can perform a variety of tasks, including facing, threading, knurling, drilling, boring, reaming, and taper turning.

In essence, while lathes provide basic turning functions, turning centers, such as a Vertical Turning Center, offer a more comprehensive range of capabilities, making them a versatile option in a machining environment.

Understanding these fundamental concepts about Vertical Turning Centers not only aids in making informed decisions about your machining needs but also opens up new possibilities in the realm of CNC machining. After all, precision machining isn’t just about cutting metal; it’s about harnessing the right technology to deliver superior results.

The Advantages of Vertical Turning Centers

The world of manufacturing is teeming with various machines, each designed to perform specific tasks. But, if there’s a machine that stands out for its versatility, efficiency, and precision, it’s the Vertical Turning Center. This powerhouse of a machine offers numerous benefits, including a compact and heavy-duty design, optimal use of gravity for stability, a smaller footprint, and suitability for heavy workpieces and complex parts.

Compact and Heavy-Duty Design

The strength of a Vertical Turning Center lies in its architecture. As we at TMC Technologies have observed, these machines are designed to be both compact and heavy-duty. This unique combination allows for efficient and accurate machining, even for the most demanding hard turning applications. The robust machine design, including a heavy-duty linear guide design for X and Z-axes, ensures long-term performance and maintainability.

Use of Gravity for Stability and Accuracy

One of the most significant advantages of Vertical Turning Centers is their strategic use of gravity. With the workpiece’s weight going straight down into the machine’s foundation, stability is reinforced, and inaccuracies are minimized. This unique feature dramatically reduces the clamping force needed for workpiece holding, enabling the machine to handle larger and heavier workpieces without compromising on precision.

Smaller Footprint Compared to Horizontal Turning Centers

Space is a precious commodity in any manufacturing setup. Vertical Turning Centers, with their vertical orientation, typically have smaller footprints than their horizontal counterparts. This aspect makes them an ideal choice for manufacturing units where space is at a premium, without compromising on the machine’s capabilities.

Suitable for Heavy Workpieces and Complex Parts

Vertical Turning Centers are ideally suited for heavy-duty cutting of large and heavy workpieces. They are designed with a rotating table to support large workpieces in conjunction with a bridge-type construction for the X-axis. This combination improves cycle times and overall efficiency. Furthermore, some models offer options for live spindle, live tooling, and a C-axis for more complex workpieces, further enhancing their versatility.

In conclusion, Vertical Turning Centers are more than just another machine on the manufacturing floor. They are a testament to the power of innovative design and the strategic use of physical forces. As we continue to push the boundaries of manufacturing capabilities at TMC Technologies, we remain committed to leveraging the best that technology has to offer. And Vertical Turning Centers are undoubtedly a part of that commitment.

Key Features of a High-Quality Vertical Turning Center

As a leading provider of top-tier components and additional machining services, we at TMC Technologies understand the essentials of a high-quality vertical turning center. Let’s delve into the key features that make these machines the backbone of precision and efficiency in any machining shop.

Maximum Cutting Diameter, Length, and Swing

A high-quality vertical turning center offers a considerable maximum cutting diameter, length, and swing. These parameters, such as the Ø15.75 in cutting diameter, 17.72 in cutting length, and Ø19.69 in swing, set by the Okuma V40R, allow the machine to accommodate large and complex workpieces. This flexibility ensures that a wide range of industries, from automotive to aerospace, can benefit from the precision and efficiency of vertical turning centers.

Rapid Traverse Speed in X and Z Directions

The rapid traverse speed in the X and Z directions is another critical feature. This refers to the speed at which the cutting tool moves along the X and Z axes when not engaged in cutting. A high rapid traverse speed, such as the Okuma V40R’s 78.74 fpm, allows the machine to complete non-cutting movements quickly, reducing idle time and increasing overall productivity.

Spindle Speed and Power

The spindle speed and power are crucial determinants of the vertical turning center’s performance. For instance, the Okuma V40R’s spindle operates at a speed of 25 to 2,500 min⁻¹ and delivers power up to 30/25 hp. This range of spindle speed and power enables the machine to handle a variety of materials with different properties, enhancing its versatility.

Options for Live Spindle, Live Tooling, and a C-Axis

A high-quality vertical turning center often comes with options for live spindle, live tooling, and a C-axis. As we have previously discussed, the introduction of a C-axis in vertical turning centers allows for intricate multi-axis machining operations. Live spindles and live tooling, on the other hand, increase the range of operations that can be performed, including drilling, milling, and tapping. This combination of features enables the production of complex parts with high precision and efficiency.

In conclusion, these key features define the performance and versatility of a high-quality vertical turning center. They allow for the efficient production of precise and complex components, making vertical turning centers an invaluable asset in any machining operation. At TMC Technologies, we harness these features to provide our clients with top-tier CNC lathe parts and additional machining services, ensuring the accuracy and longevity of their machinery.

Popular Models of Vertical Turning Centers

In the world of CNC machining, not all vertical turning centers are created equal. Some models, due to their advanced features and innovative design, stand out as the top choices for businesses seeking to enhance their production efficiency and precision. Let’s delve into some of the most popular models in the market today:

CTV 160 and CTV 250: Linear Vertical Lathes for High Productivity

The CTV 160 and CTV 250 models are renowned for their high productivity. Linear vertical lathes, these machines are designed to automate manufacturing processes, achieving efficient production rates without compromising on precision. Their robust design supports heavy-duty cutting of large and complex parts, making them an ideal choice for businesses that value productivity and accuracy.

These models are also equipped with advanced control systems that allow for smooth and precise tool movements, ensuring consistent high-quality output. Whether your manufacturing needs are simple or complex, the CTV 160 and CTV 250 linear vertical lathes are equipped to handle the task with aplomb.

CTV 250 DF: Designed for Constant Velocity Joints

The CTV 250 DF is a model specialized for the production of constant velocity joints. These critical components, used in the automotive industry, require high precision and consistency in manufacturing. The CTV 250 DF excels in this area, ensuring accurate and efficient production of constant velocity joints.

Furthermore, this vertical lathe model is designed for automation, adding an extra layer of efficiency to your production processes. With the CTV 250 DF, you can optimize your production of constant velocity joints, ensuring high-quality output while minimizing production time.

CTV 315: Another High-Productivity Linear Vertical Lathe

Lastly, the CTV 315 is another high-productivity linear vertical lathe that deserves a mention. Similar to the CTV 160 and CTV 250 models, this machine is designed for automation, achieving high productivity rates. It supports heavy-duty cutting of large and complex parts, making it ideal for businesses with demanding manufacturing requirements.

At TMC Technologies, we recognize the value of these superior vertical turning center models. We leverage their innovative features and capabilities to provide our clients with high-quality CNC lathe parts, ensuring the accuracy and longevity of their machinery.

In the next section, we explore how TMC Technologies plays a pivotal role in the vertical turning center revolution, offering unrivaled quality and service in the CNC machining industry.

TMC Technologies and the Vertical Turning Center Revolution

In the realm of CNC machining, TMC Technologies stands as a beacon of innovation and quality. Our commitment to delivering precision and quality in every product and service we offer has made us a trusted partner for businesses across various industries. We understand the significance of each component that goes into your machinery, and that’s why we don’t just provide parts—we deliver solutions tailored to your specific manufacturing needs.

TMC Technologies’ Unique Selling Proposition

At TMC Technologies, we believe in more than just the manufacturing of high-quality CNC lathe parts. We aim to offer a complete, end-to-end solution that caters to your unique business needs. Our unique selling proposition lies in our dedication to precision and quality, combined with our ability to deliver fast turnaround times and exceptional customer service.

Our new vertical machining center is a testament to our commitment to driving innovation in the CNC machining industry. Equipped with advanced features such as temperature stability through integral cooling, user-friendly CNC controls, and on-board probing for part location and feature inspection within the cutting cycle, our vertical turning center provides an efficient and precise solution for your manufacturing needs.

TMC Technologies’ High-Quality CNC Lathe Parts

When it comes to our CNC lathe parts, our focus is on delivering exceptional precision and consistency. Our new vertical turning center, with its 3-, 4-, and 5-axis capabilities, enables us to process diverse part shapes, thus opening a world of possibilities for your manufacturing projects.

Quality control is an integral part of our manufacturing process. Every part we create is subjected to rigorous inspection to ensure it meets our high standards of precision manufacturing. Whether you need parts for small or large part machining in a low- or high-volume production environment, we are here to provide you with high-quality, consistent results.

Additional Machining Services Offered by TMC Technologies

Beyond just manufacturing parts, we offer a range of additional machining services, including design & CAD services, fabrication & assembly, and supply chain management. Our CNC machinery can handle multiple projects at once, accommodating both small-scale and large-scale orders.

With our comprehensive machining services, we aim to be your one-stop-shop for all your machining needs. Whether you need high-quality CNC components, additional machining services, fast turnaround times, or exceptional customer service, TMC Technologies is the partner you can trust.

In conclusion, our commitment to driving innovation, delivering high-quality CNC lathe parts, and offering additional machining services backed by outstanding customer service, make us an ideal partner in your vertical turning center revolution journey. We are not just a manufacturer; we are a partner dedicated to helping you maximize efficiency, precision, and reliability in your production processes.

Conclusion: The Future of Vertical Turning Centers

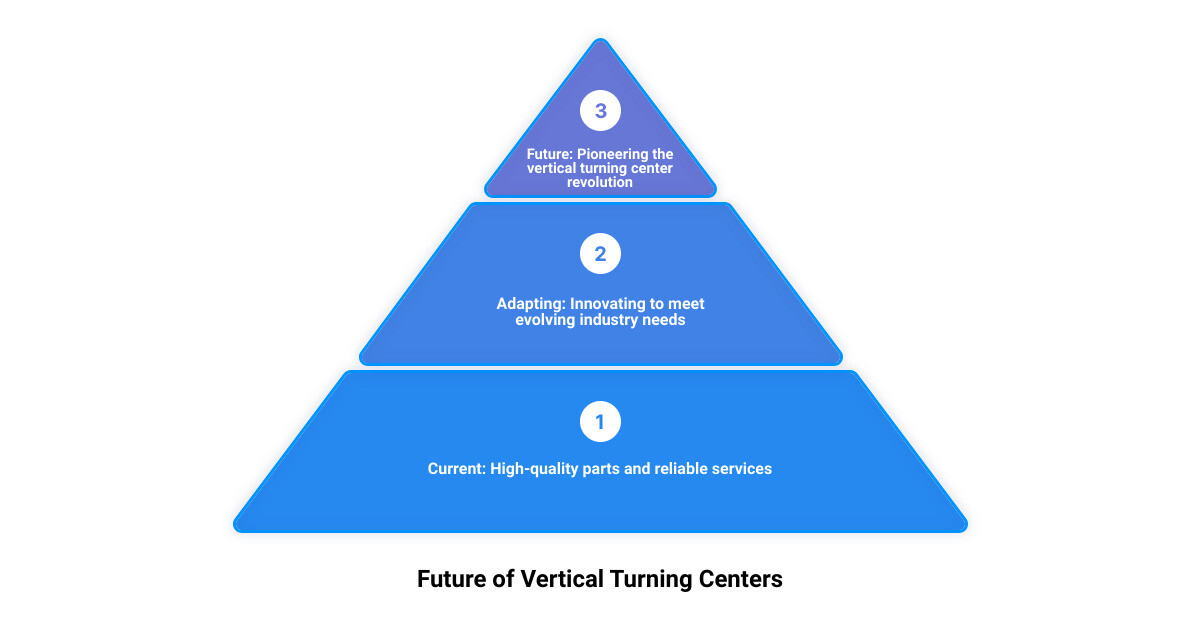

As we look to the future, the vertical turning center revolution is just beginning. The advent of high-precision tools, advanced sensors, and control systems is setting the stage for unprecedented levels of efficiency, precision, and productivity. At TMC Technologies, we are not just observers of this revolution; we are active participants and pioneers.

The role of high-precision machine tools is becoming increasingly pivotal in the CNC machining process. With the ability to fabricate parts from a variety of materials with exacting tolerances, these machines are transforming the manufacturing landscape. At TMC Technologies, our CNC Horizontal Machining Centers are designed to produce complex components with exacting tolerances, ensuring that your parts are created accurately and consistently with the highest quality.

In addition to high-precision machine tools, advanced sensors and control systems are playing a crucial role in the future of CNC machining and vertical turning centers. These systems are responsible for controlling the movement and operation of the machine tools, ensuring that they function optimally and produce the desired output. At TMC Technologies, we leverage advanced CNC capabilities, including conversational control programming, to ensure the flexibility and capability of our vertical turning centers.

The future of vertical turning centers also lies in the hands of manufacturers who are able to adapt to the evolving needs of various industries. As technologies continue to evolve, so must our machining processes. At TMC Technologies, we continuously innovate and adapt to the changing landscape, ensuring that we remain at the forefront of the vertical turning center revolution.

We are excited about what the future holds for vertical turning centers. With the continuous advancements in technology, we are confident that we can continue to provide the highest quality parts and the most reliable services to our customers. We are committed to being your partner in the vertical turning center revolution, providing you with the tools and expertise you need to succeed.

In the world of manufacturing, the right choice of machinery can make a significant difference in efficiency, precision, and cost-effectiveness. Vertical turning centers have proven to be a valuable asset in this regard. As we step into the future, we at TMC Technologies are proud to be part of this exciting journey, and we look forward to helping our customers navigate the ever-evolving landscape of CNC machining.

In conclusion, the vertical turning center revolution is a testament to the power of innovation and technology in manufacturing. With every passing day, we are getting closer to realizing the full potential of these remarkable machines. At TMC Technologies, we are committed to being a part of this revolution, and we invite you to join us on this journey towards a future of unparalleled efficiency, precision, and productivity.