Introduction to Precision Machined Components

Welcome to the world of precision machined components. Quite a mouthful, isn’t it? Don’t sweat it. We’ll dissect this term, making it as clear as your morning coffee.

As a manufacturer, you understand the importance of quality parts for your industrial machinery. Every unwilling screw or a millimeter of variance can disrupt your machine’s overall performance, efficiency, and lifespan. You’re likely nodding because you’ve experienced this. Well, you’re not alone.

Definition and Importance of Precision Machined Components

Here’s an easy-to-swallow definition: precision machined components are tiny heroes forged through a process called precision machining. They involve designing and developing parts, precisely cut from materials like aluminum, copper, plastics, or steel.

This extraordinary process ensures the perfect fit and high functionality of these small components inside big gizmos, regardless of the industry. From the minute grooves in your car engine to the complex elements flying high in aerospace, precision components are everywhere.

At TMC Technologies, we’re proud to be part of this transformative engineering process. We see firsthand how precision components heighten product quality across multiple industries, optimize performance and maximize efficiency.

The Role of Precision Machined Components in Modern Engineering

Today, our modern world is held together and driven forward by these precision components. Without them, transformative industries like aerospace, automotive, HVAC, and manufacturing would pause, stutter, or collapse. Think house of cards with missing parts. Understanding and valuing precision machined components is the golden key to engineering wonders.

- Aerospace: Precision components ensure the safe and perfect function of intricate parts.

- Automobile: Engine parts need exact requirements for optimum performance.

- HVAC: High-quality components enhance the functionality of modern equipment.

- Manufacturing Industry: Precision machining helps maintain quality standards.

Feeling a bit clearer? Great! Let’s make things even more palpable with an infographic.

Understanding the Precision Machining Process

Precision machining is a marvel of modern engineering. With it, we can turn a block of raw material into a finely-tuned component, ready to play its part in a larger machine. But how does this process work? Let’s dive into the details!

The Process of Precision Machining

Think of precision machining as sculpting, but instead of clay or marble, the raw material is metal or plastic. The process starts by taking a large chunk of this material, then gradually removing pieces until we’re left with a part that fits our exact specifications.

The secret to this process is a type of technology called Computer Numerical Control (CNC). This genius tech uses computer-aided design (CAD) and computer-aided manufacturing (CAM) software to guide the machine’s movements. This way, we can make incredibly precise cuts, down to the tiniest fraction of an inch.

Beyond the software, the choice of material is vital. The most common materials used in precision machining are metals like carbon steel, stainless steel, aluminum, and alloys. But we can also work with plastics and composites, depending on the job’s needs.

Examples of Precision Machines: Milling Machines, Lathes, Grinders, Laser Cutters, WaterJets, Non-traditional machines (EDM, ECM)

Now, let’s talk about the machines that make all this possible. They are the real stars of the show, each with its unique talents.

First, we have Milling Machines. These guys are the workhorses of our operation. They use rotary cutters to remove material, making them perfect for jobs that require versatility.

Next up, the Lathes. These machines are essential for creating cylindrical parts with high precision, such as axles and shafts. In CNC turning, the workpiece rotates, and a linearly moving cutting tool shapes the material.

Then, we have Grinders, the smoothing agents of the manufacturing world. They remove the smallest bits of material, improving the accuracy of the final product. These machines are crucial in industries where surface finish and dimensional accuracy are paramount.

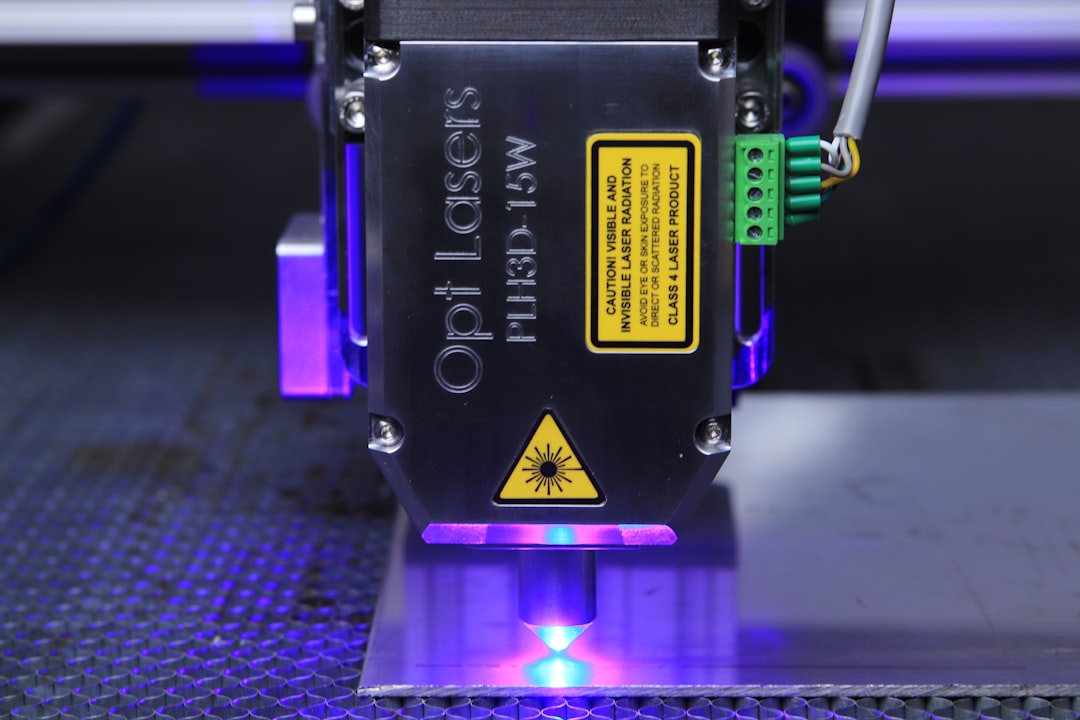

Laser Cutters and WaterJet Machines are other examples of precision machines. They use a high-frequency laser beam and high-pressure water streams, respectively, to cut materials with remarkable precision. These machines can work with both metals and non-metals, making them versatile tools in the manufacturing industry.

Finally, there are the Non-traditional Machines, including Electrical Discharge Machines (EDM) and Electrochemical Machines (ECM). These machines use electrical discharges or chemical processes to shape materials. They’re preferred when working with the hardest metals that are difficult to machine with traditional milling machines.

In conclusion, precision machining is a complex but fascinating process. It’s the backbone of many industries, from automotive to aerospace. And at the heart of it all are the precision machines, carefully crafting parts with incredible accuracy. At TMC Technologies, we’re proud to be part of this process, helping to drive the future of engineering with our top-quality precision machined components.

The Application of Precision Machined Components in Various Industries

Precision machined components, crafted with utmost accuracy, are the building blocks of numerous industries. Be it automotive, aerospace, medical, or electronics, precision machining is the lifeline that ensures functionality and reliability. At TMC Technologies, we’re not just part of this process, we’re leading it.

Precision Machined Components in the Automotive Industry

In the automotive world, every part counts. From engine components to chassis elements and custom fasteners, precision machined components are the pulse of every vehicle. These components ensure the right fit and function, contributing to the vehicle’s longevity and performance. We, at TMC Technologies, are committed to providing consistent, efficient machining services for the automotive sector.

Precision Machined Components in the Aerospace Industry

The aerospace sector is another arena where precision is not just a requirement, but a necessity. Precision machined components help build components that meet stringent safety and performance standards. We work under the AS9100, a universally accepted quality standard for manufacturing, and use exceptional metals to create environmentally friendly solutions.

Precision Machined Components in the Medical Industry

In medical and dental industries, precision machining is critical. In an industry where even the slightest error can have significant consequences, there’s no room for error. Precision machining is essential in the production of medical devices and surgical tools, ensuring a proper fit with other components. We, at TMC Technologies, manufacture high-quality parts that ensure the reliability of medical equipment.

Precision Machined Components in the Electronics Industry

In the electronics industry, precision machined components such as stand-offs, spacers, retainers, bushings, and shafts play a crucial role. These parts not only enhance the assembly process but also ensure the proper functioning of electronic devices. Our team at TMC Technologies is experienced in creating these precision parts ensuring your electronics perform at their best.

Precision machining has revolutionized these industries, and at TMC Technologies, we’re proud to be part of this revolution. Our commitment to quality and precision ensures that we meet the unique needs of each industry, driving innovation and progress.

The Role of CNC Technology in Precision Machining

Understanding CNC Technology

So, you ask, what exactly is CNC technology? Simply put, CNC stands for Computer Numerical Control. This technology is the backbone of precision machining. It involves the use of computer-controlled machines to create precision machined components with exact dimensions.

These machines operate under sophisticated software, allowing for greater efficiency and less variance compared to other metal fabrication methods. This means that CNC machines work faster and produce fewer errors than human-operated machines, saving time and reducing material waste.

The Use of CNC Machines in Building Custom Metal Parts

CNC machines play a crucial role in building custom metal parts. At TMC Technologies, we use the power of CNC technology to create components with high accuracy, repeatability, and efficiency. This is a testament to the importance of precision in the manufacturing process.

Using CNC technology, we’re able to create a wide range of complex metal parts. For instance, our machine parts manufacturers use computer numerically controlled machines (CNC machines) to create a broad range of complex metal parts.

We also use CNC machines to execute designs created with computer-aided design (CAD) software. This software allows us to make a 3D diagram of a sketch, which we then put into the CNC machines. The machines then remove the raw material to develop the precise parts, following a path of accuracy based on the software instructions. This process allows us to make precise cuts with fewer errors, and to repeatedly generate hundreds of identical parts with similar specifications and tolerances.

CNC technology and precision machines together form the cornerstone of our precision machining parts manufacturing process. This combination contributes to the production of reliable, high-quality components that meet the needs of various industries.

At TMC Technologies, we’re not just creating parts – we’re crafting components that meet stringent quality standards and precise specifications. Each CNC lathe part that comes out of our facility is a testament to our commitment to detail and accuracy. From prototype parts to full production runs, we deliver the highest quality of CNC lathe parts, competitively priced, and with fast delivery times.

In conclusion, CNC technology plays a pivotal role in the creation of precision machined components. Its importance in ensuring accuracy, efficiency, and longevity in various manufacturing processes cannot be overstated. At TMC Technologies, we’re proud to harness the power of CNC technology to deliver high-quality components that meet the exact specifications of any project.

TMC Technologies: A Leader in Precision Machined Components

Overview of TMC Technologies

As the manufacturing world spins fast, one name comes up top for precision machined components – TMC Technologies. We are a company that has grown strong roots in the industry over the past 30 years. Our rich history and experience have allowed us to develop advanced technologies and skillfully use them to deliver components that meet strict tolerance and high-quality standards. Our team is made up of highly skilled engineers and technicians, all adept at handling complex requirements and delivering precise solutions.

At TMC Technologies, we understand the importance of each component in a machine, no matter how small. We believe in quality, efficiency, and affordability. These are the principles that guide our entire production process.

TMC Technologies’ Unique Selling Proposition: High-Quality CNC Lathe Parts and Additional Machining Services

When it comes to precision machined components, our unique selling proposition is our unwavering commitment to precision and quality. We don’t just produce components; we create parts that are reliable, durable, and precise. This is because we understand that the longevity and optimal performance of your equipment rely on the quality of each component.

We don’t just manufacture components. We offer a comprehensive range of services, from design and CAD services to fabrication and assembly. Our capabilities extend to CNC lathe operations, and diverse secondary equipment, including heat treating. This means that when you partner with us, you get more than just components. You get the complete package – all under one roof.

But our commitment to quality doesn’t mean we compromise on speed. We understand the urgency often associated with the need for precision parts. Therefore, we strive to deliver short lead times without sacrificing quality.

When you choose us, you’re not just picking a supplier. You’re choosing a partner who understands your needs, values quality, and delivers precision. You’re choosing a company that doesn’t just meet expectations but exceed them. That’s why TMC Technologies is more than a manufacturer; it’s a leader in the world of precision machined components.

In the end, it all comes down to our commitment to quality, efficiency, and customer satisfaction. These are the pillars that hold TMC Technologies high in the industry. And it is this commitment that will continue to drive us into the future of precision machined components.

The Future of Precision Machined Components

In a rapidly evolving world, the realm of precision machined components is no exception. The future of this industry is teeming with possibilities and opportunities, all driven by technological advancements.

The Impact of Technological Advancements on Precision Machining

The ushering in of the era known as Industry 4.0 is reshaping the future of machined components manufacturing. In this new age, machines, systems, and even products are interconnected, communicating and making decisions autonomously. This level of interconnectivity enhances precision, efficiency, and opens up new avenues for innovation.

The rise of smart factories is also having a significant impact, revolutionizing how we design, manufacture, and deliver precision machined components. Essentially, these advancements herald a future where precision, efficiency, and quality are the defining hallmarks of every component we produce.

Moreover, other technological advancements like AI and machine learning are also finding their place in precision machining. They contribute to further improving the accuracy and efficiency of the machining process, pushing the boundaries of what’s possible.

The Role of Precision Machined Components in the New Era of Engineering

In this new era of engineering, precision machined components are more critical than ever. They are the linchpin of high-quality production, playing a pivotal role in ensuring accuracy, efficiency, and longevity in various manufacturing processes.

These components, whether they are engine parts, custom fasteners, or intricate parts for navigation systems, are produced with the highest level of accuracy. This ensures they fit perfectly and function optimally, contributing to the overall performance and longevity of final products across various industries.

At TMC Technologies, we’re not just observers of this new era, we’re active participants. We understand the importance of staying ahead of the curve, constantly innovating, and adapting to meet the needs of our customers. We’re committed to ensuring the accuracy, performance, and longevity of the precision machined components we produce, driving progress across industries.

In conclusion, the future of precision machined components is bright and promising. With each technological advancement, we’re pushing the boundaries of what’s possible, driving innovation, and setting new standards in precision machining. As we move forward, we at TMC Technologies are excited to continue leading the way, delivering high-quality, reliable, and efficient solutions for all your precision machining needs.

Conclusion: The Importance of Precision Machined Components in Modern Engineering

In the bustling realm of modern engineering, precision machined components are the unsung heroes. They’re the cogs that keep the wheels of progress turning, driving innovation and efficiency across a wide array of industries, from automotive and aerospace, to medical and electronics.

Every part matters. Think about it. Even the smallest screw plays a pivotal role in the overall performance, efficiency, and longevity of a machine. In industries such as automotive and aerospace, the quality and reliability of these components can mean the difference between success and failure.

At TMC Technologies, we understand the stakes and are committed to delivering top-notch quality. We use advanced Computer Numerical Control (CNC) equipment to meticulously craft parts designed to optimize the performance of various machinery. Our expertise in precision CNC components manufacturing allows us to exceed expectations and contribute to the success of your business.

Precision machining is the cornerstone of modern manufacturing. It’s a process that takes large pieces of material and finely shapes them with advanced CNC equipment to exact specifications. It’s the art of creating finely-tuned components that power our world.

In an era where technology is rapidly evolving, staying ahead of the curve is vital. By choosing a reliable machining components manufacturer like us, you’re not just investing in high-quality, precision-engineered components. You’re investing in the future of your business, paving the way for continuous growth and innovation.

In conclusion, precision machined components are indeed a game-changing factor in modern engineering. Their precision, efficiency, and innovation are integral to the advancement of various industries and their ability to deliver high-quality products and services.

Let’s embrace the new era of engineering together. With TMC Technologies, the future is bright and promising.